Concrete intercepting device and using method thereof

An interception device and concrete technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of unbearable time cost and long waiting time, and solve the difficulty of concrete scheduling, improve sealing and fixing strength , to strengthen the effect of the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

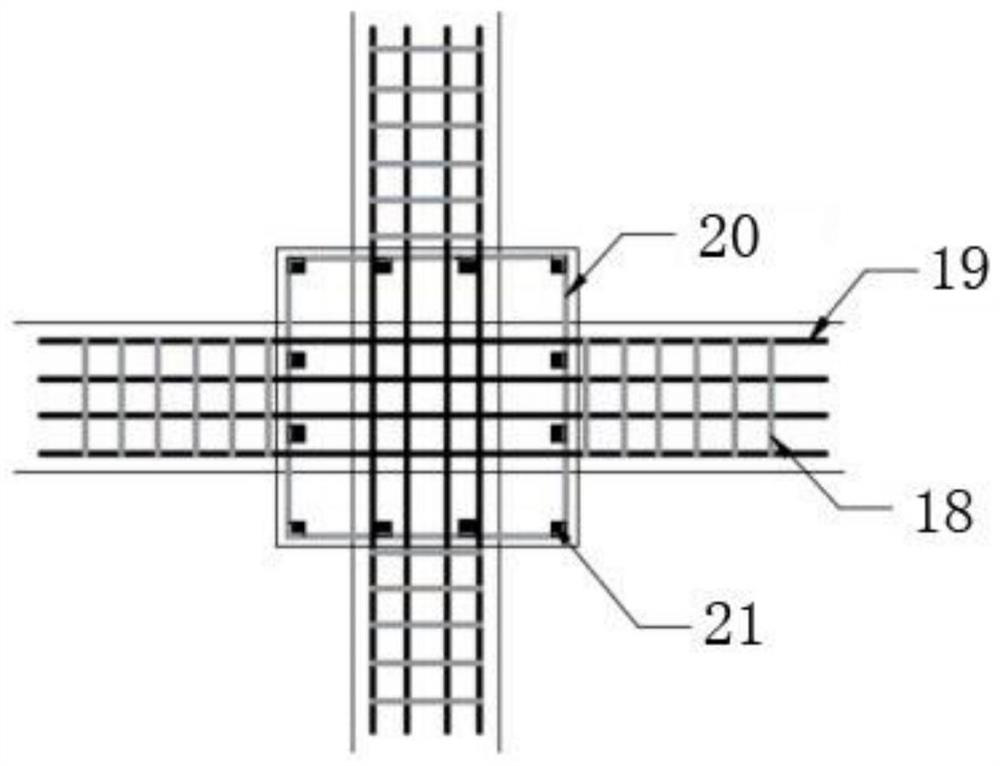

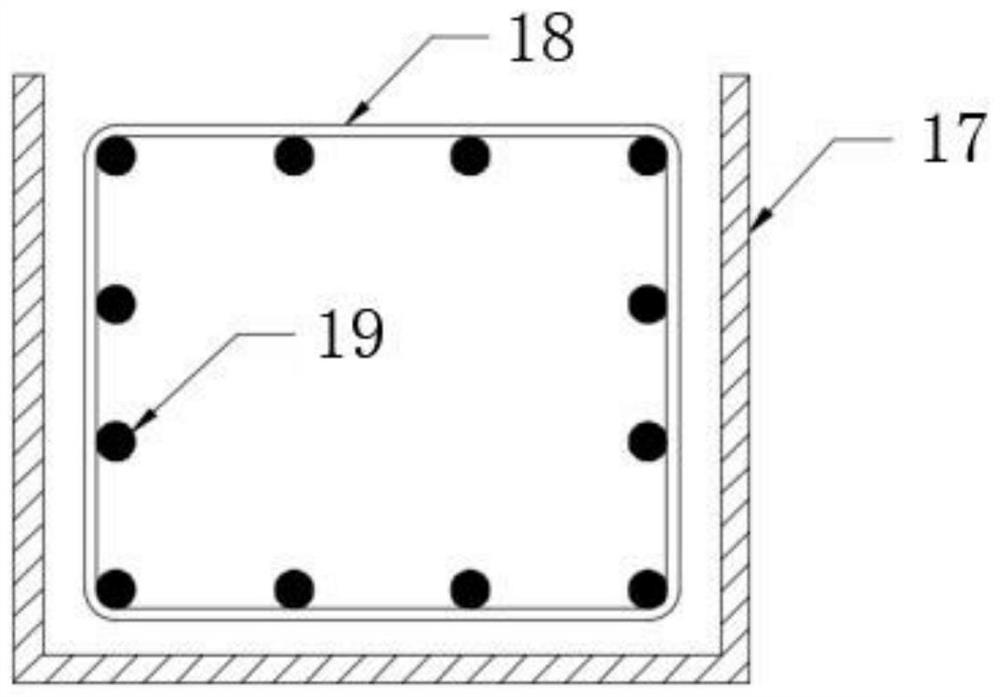

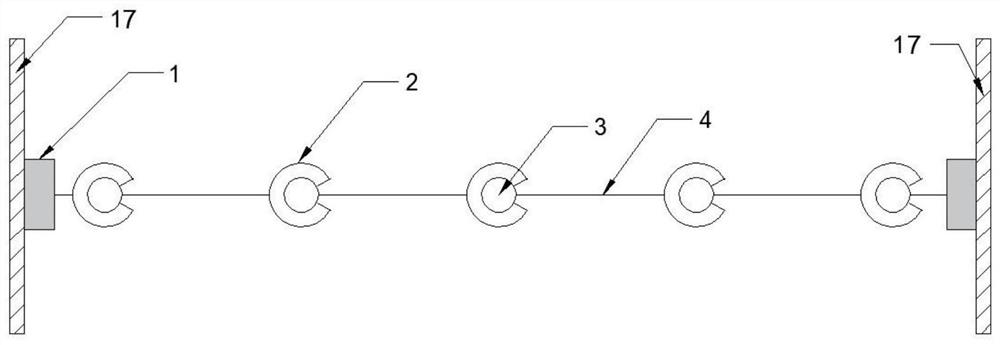

[0045] See attached Figure 1-3 , 5-7, 10-14, the present embodiment provides a concrete interception device, including a support body 1 and an interception unit; the support body 1 is a rigid vertical rod structure, which is used to provide support to fix the interception device on The template frame 17 includes an edge vertical rod 101 and a central vertical rod 102. There are at least two edge vertical rods 101, which are fixedly installed close to the vertical side wall of the template frame 17. The central vertical rod 102 is vertically arranged on Between the vertical bars 101 at the two edges. The top of the edge vertical bar 101 is provided with an L-shaped ear 103 extending outward to the outer wall of the formwork, the outer plate of the ear 103 extends downward parallel to the edge vertical bar 101, and the outer plate is set At least one through hole 104, the through hole 104 is a nail hole or an internal thread hole; the bottom of the edge vertical bar 101 is pro...

Embodiment 2

[0056] See attached Figure 4-6 , 8-14, the difference from Embodiment 1 is that: the vertical bars constituting the support 1 include two edge vertical bars 101 and at least one central vertical bar 102; the central vertical bar 102 can be against the beam hoop ribs; the bottom of the central vertical bar 102 is also provided with positioning nails 105 .

[0057] The invention provides a method for using a concrete intercepting device, comprising the following steps:

[0058] Step S1. Install interception device:

[0059] Step S1-1. Fixing the vertical bars: vertically set the two edge vertical bars 101 against the side walls of the formwork in the formwork frame 17, and vertically set the central vertical bar 101 against the beam stirrup 18 in the middle of the formwork frame 17 Nail the positioning nails at the bottom of the edge vertical bar 101 and the central vertical bar (102) into the bottom template, and fix the ears 103 of the edge vertical bar 101 to the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com