Tray for fixing ring bobbin of bobbin winder

A winding machine and spun yarn technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve problems such as warping and weaving difficulties, yarn tension fluctuations, and affecting the shape of bobbins, and achieves improved Stability, eliminate tension fluctuation, reduce the effect of yarn climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

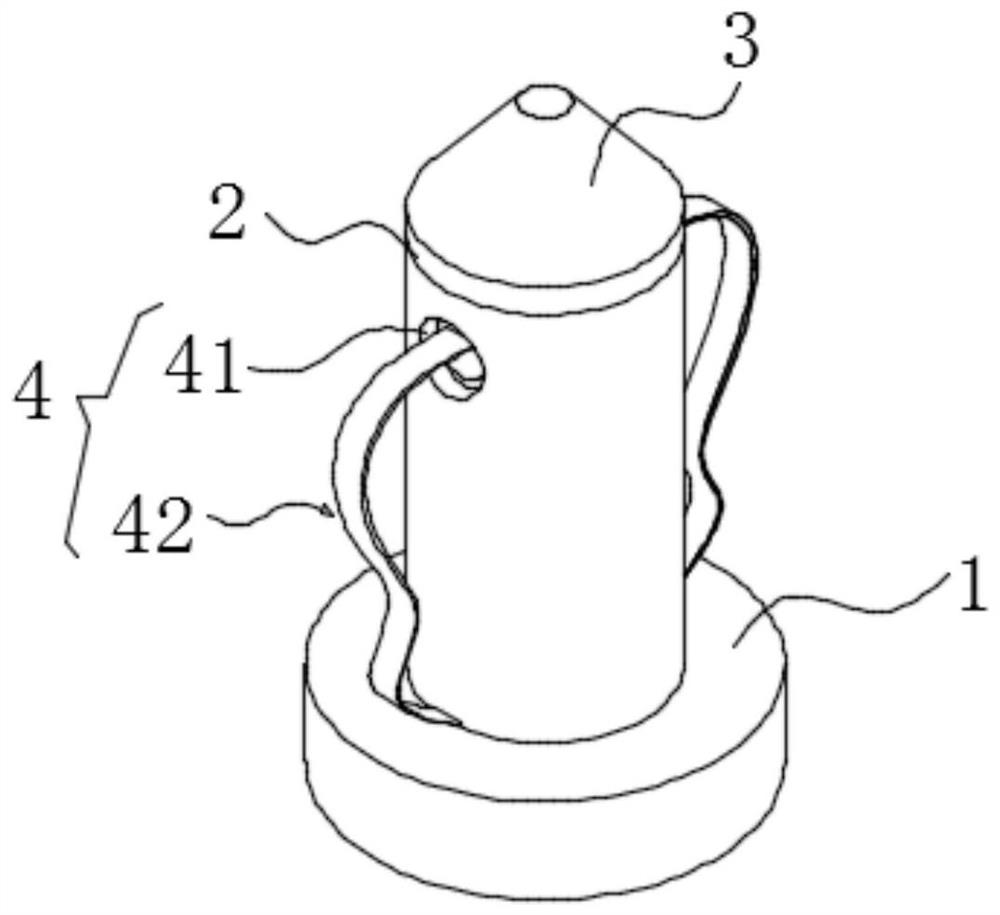

[0036] Embodiment one, with reference to Figure 1-2 , a tray for fixing the spun bobbin of a winding machine, comprising: a support tube body 2 and an expansion support assembly 4;

[0037] The bottom of the supporting tube body 2 is fixedly connected with a circular tray 1, and the top of the supporting tube body 2 is detachably connected with a tapered end 3;

[0038] The expansion support assembly 4 is arranged through the support tube body 2 , and the expansion support assembly 4 is assembled to automatically support and fix the spun yarn sleeved on the support tube body 2 .

[0039] The expansion support assembly 4 includes a circular opening 41 and an elastic support mechanism 42;

[0040] The circular opening 41 is horizontally opened on the support tube body 2 , and the elastic support mechanism 42 is provided through the circular opening 41 .

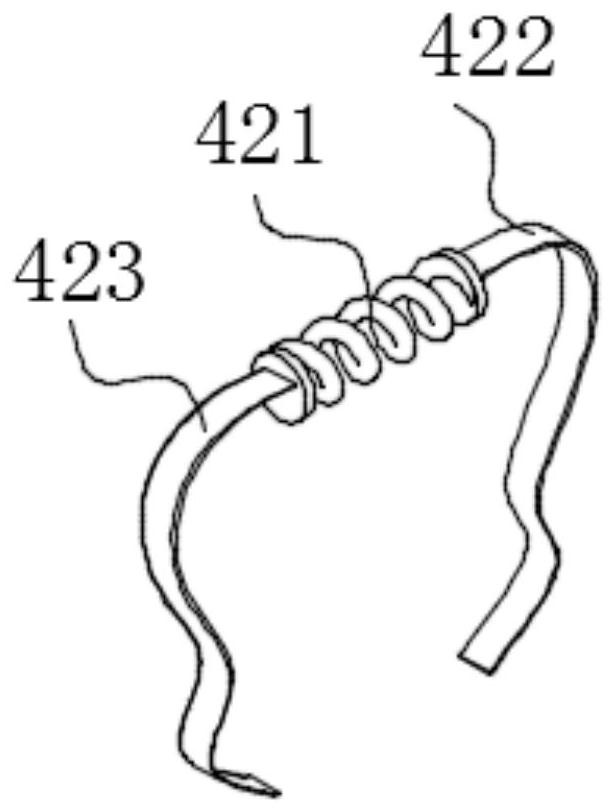

[0041] The elastic support mechanism 42 includes a first support spring 421 , a first support elastic piece 422 and a seco...

Embodiment 2

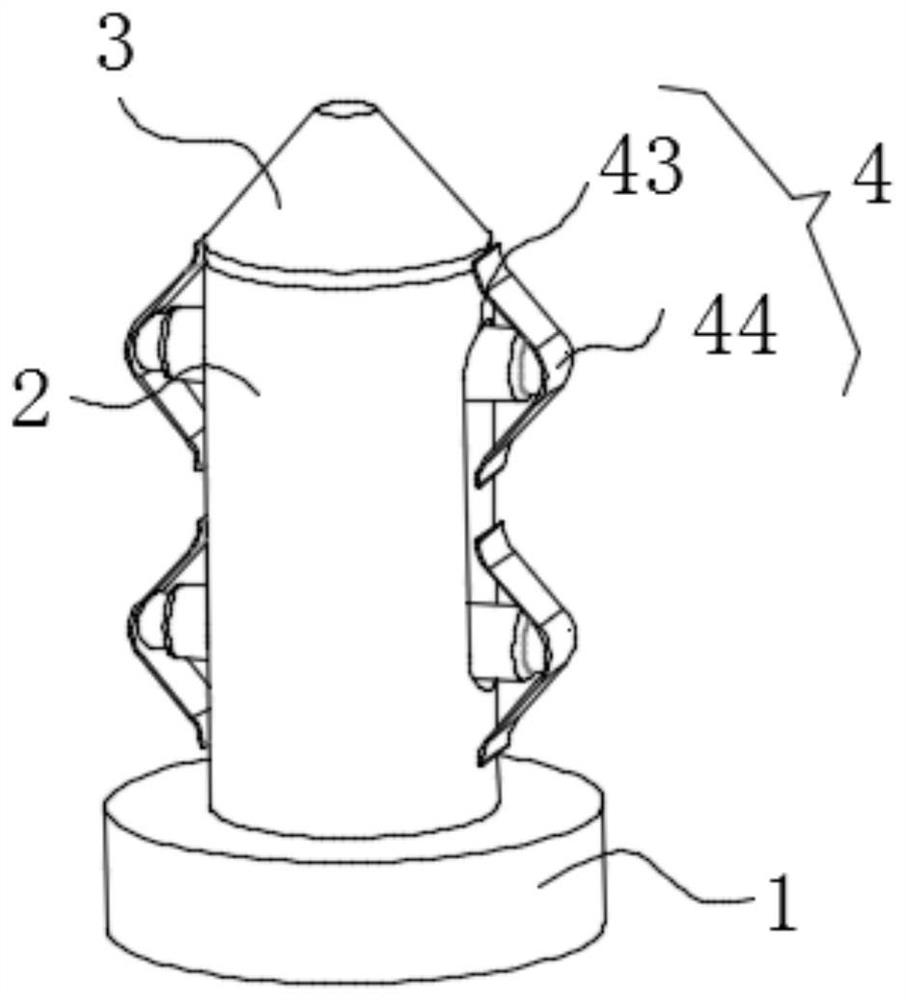

[0044] Embodiment two, refer to Figure 3-6 , a tray for fixing the spun bobbin of a winding machine, comprising: a support tube body 2 and an expansion support assembly 4;

[0045] The bottom of the supporting tube body 2 is fixedly connected with a circular tray 1, and the top of the supporting tube body 2 is detachably connected with a tapered end 3;

[0046] The expansion support assembly 4 is arranged through the support tube body 2 , and the expansion support assembly 4 is assembled to automatically support and fix the spun yarn sleeved on the support tube body 2 .

[0047] The expansion support assembly 4 includes a strip opening 43 and a support expansion mechanism 44;

[0048] The strip-shaped opening 43 runs through the support tube body 2 along the length direction of the support tube body 2 , and the support expansion mechanism 44 penetrates through the support tube body 2 and extends to the outside of the support tube body 2 through the strip-shaped opening 43 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com