Rail outline and undulatory wear sensor positioning mechanism for tracking central line of top of steel rail

A sensor, centerline technology, applied in the field of three-dimensional flexible positioning mechanism, can solve problems such as front and rear swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

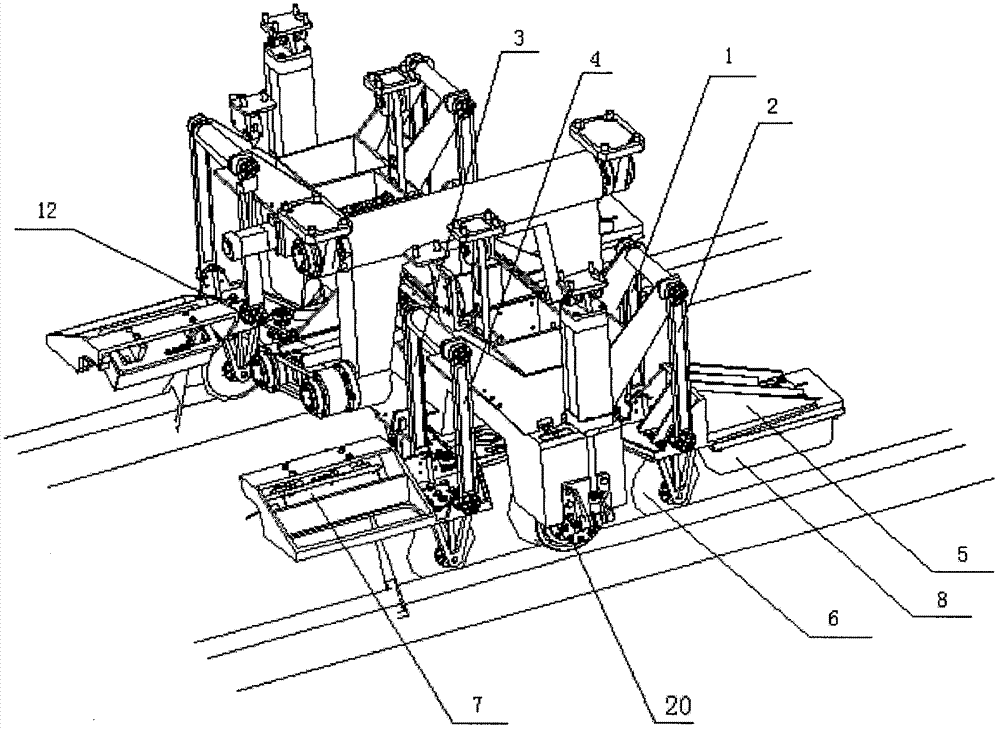

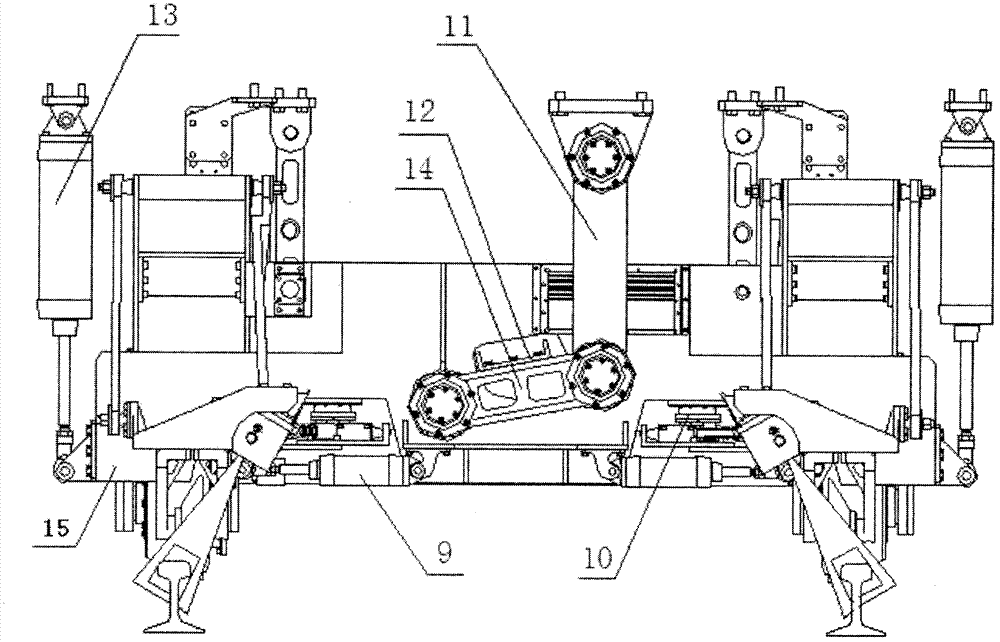

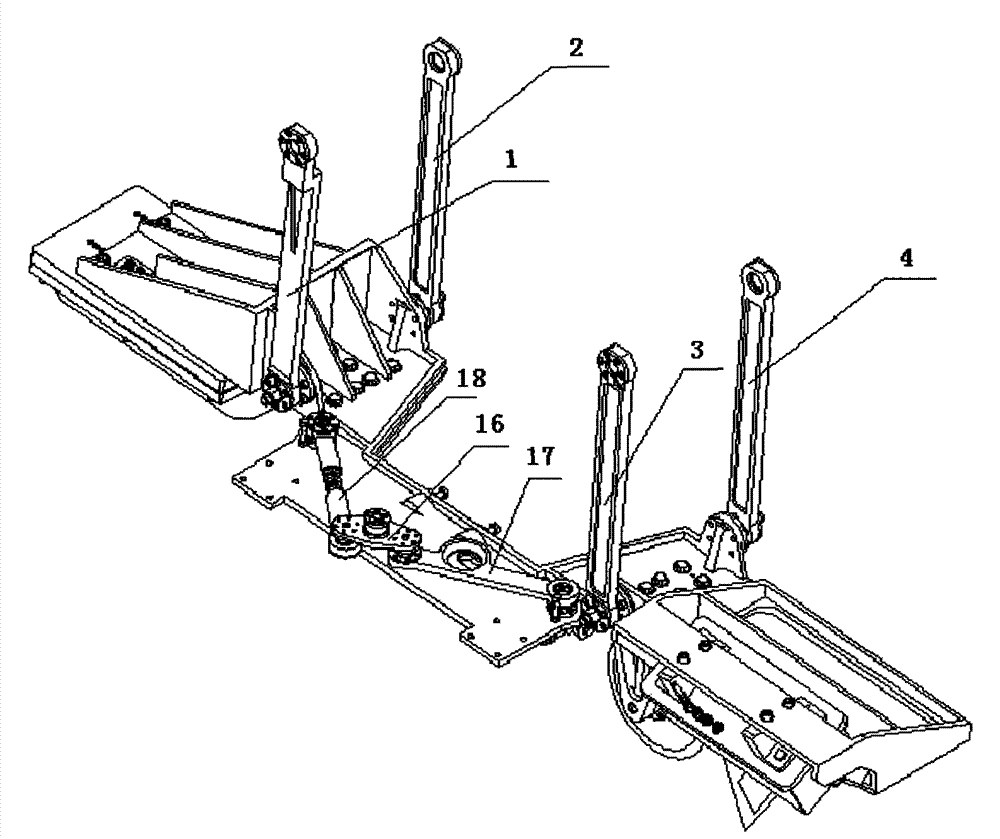

[0012] The track profile corrugation sensor positioning mechanism of the present invention, which tracks the center line of the rail top, is installed on the chassis of the detection car and moves smoothly with the train. Its main structure is as follows: figure 1 , figure 2 Shown: including main shaft beam 11, synchronous support 12, two cantilever frames 14, support beam 15 and the support wheel 20 that is arranged on the left and right bottom of support beam 15, all are provided with four connecting rods 1-4 on each side guide rail, positioning Wheel support 5, positioning wheel 6, positioning wheel supporting cylinder 9, "Z" shape connecting rod 10, master cylinder 13; supporting wheel 20 moves along the left and right sides guide rails.

[0013] The rail profile sensor 7 and the corrugation sensor 8 are respectively installed at the front and rear ends of the positioning wheel bracket 5. The top ends of the four connecting rods are all connected above the support beam 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com