Electro-hydraulic torque power device for aviation engine

An aero-engine and power device technology, applied in the field of mechanical installation and power, can solve problems such as low operating efficiency, low degree of automation, and poor anti-reaction torque effect, so as to improve operating efficiency, improve the level of automated operation, and protect against damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

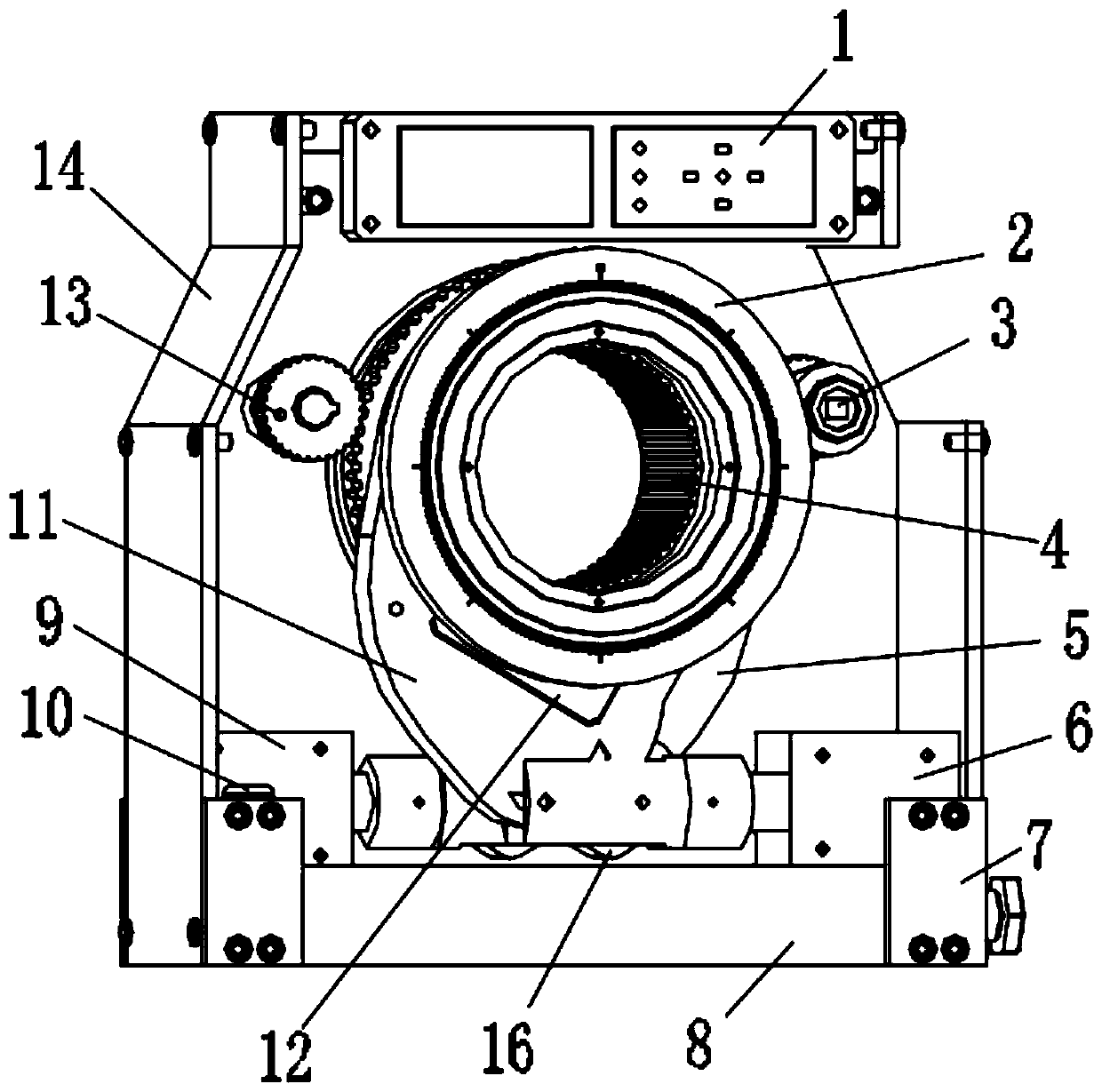

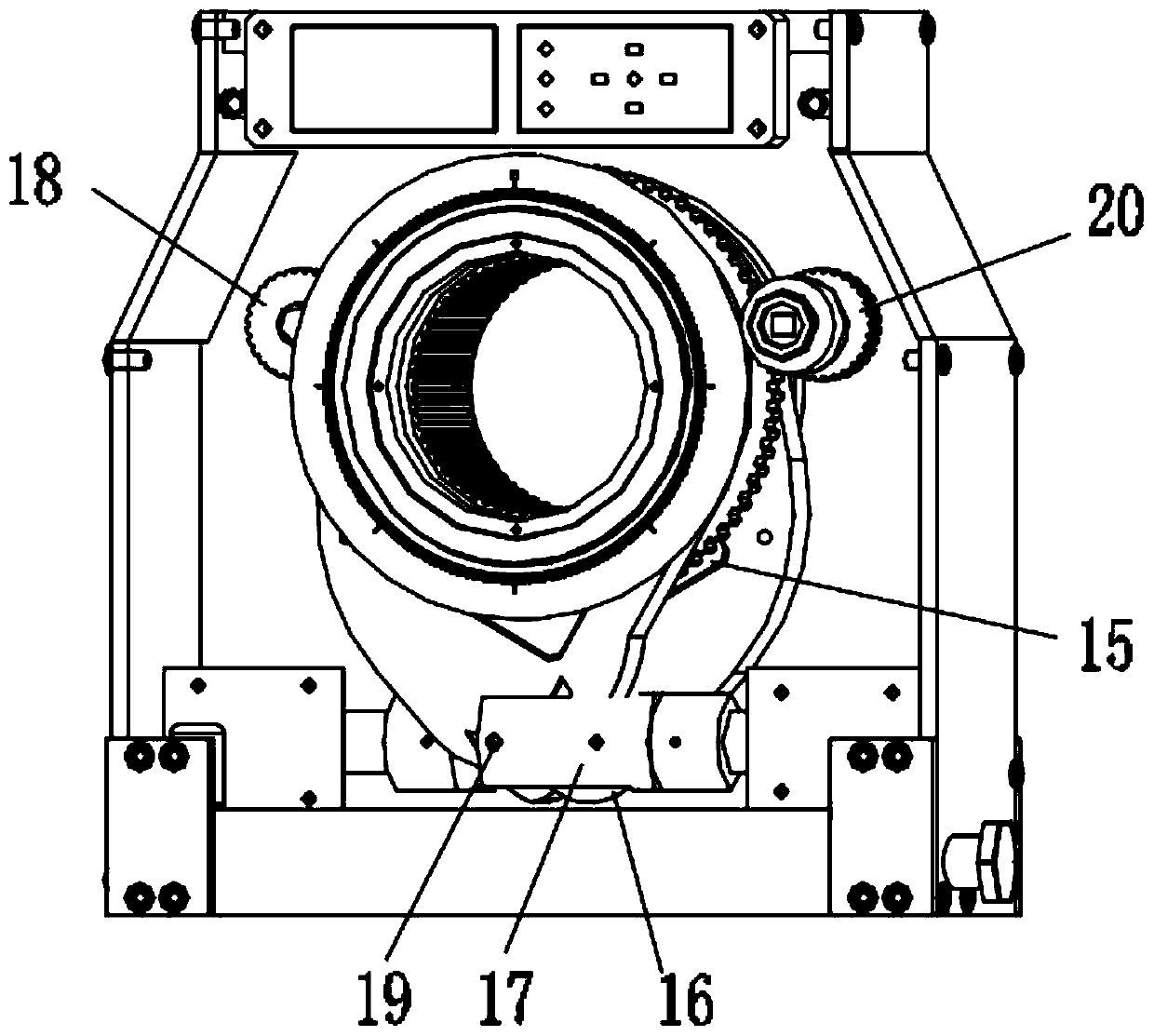

Embodiment 1

[0019] An electro-hydraulic torque power device for an aeroengine, comprising a central ratchet 4, a bearing 24, a claw 17, a driving block 6 and a driving device; two driving rings are arranged side by side on the bearing 24; the two driving rings are In the ring structure with the same structure, the inner ring is provided with an opening for installing the pawl, and the outer surface is provided with a chute 1102; the opening is provided with a spring mounting hole 1101; the pawl passes through the spring mounting hole 1101 The spring is connected to the drive ring; the central ratchet 4 is provided with two helical gears, which are respectively connected to the helical pawls in the inner rings of the two drive rings; the pawl meshes with the central ratchet 4 and is driven by the drive ring; The claw 17 is provided with a U-shaped opening, and two sets of connecting through holes are provided on both sides of the U-shaped opening; the driving block 16 is provided with a thr...

Embodiment 2

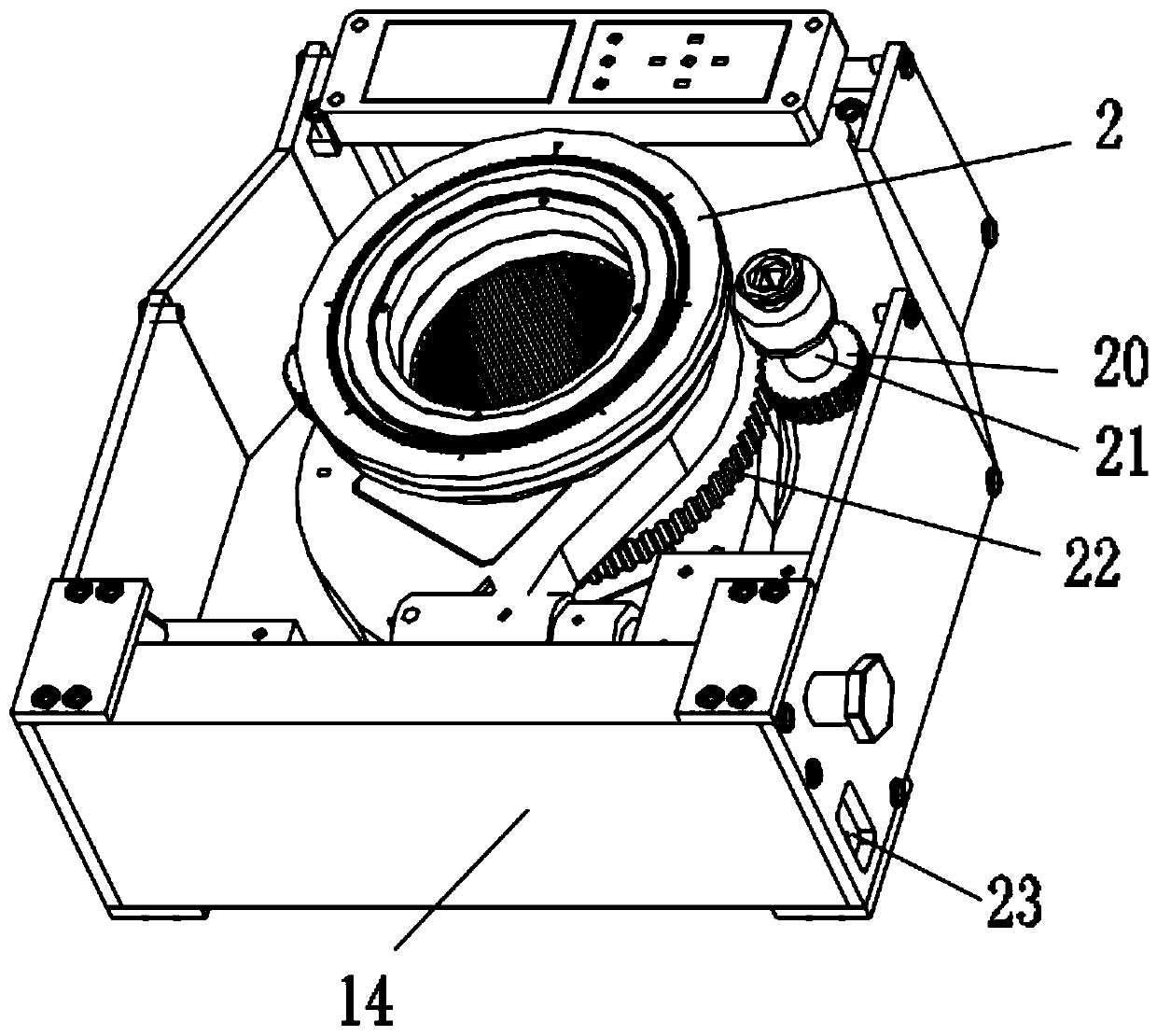

[0021] An electro-hydraulic torque power device for an aero-engine, the driving device includes an oil cylinder, an oil block 8, a diverter valve 7 and an oil inlet port 23; the oil block 8 is provided with an oil inlet port 23, and the oil block 8 Oil cylinders are respectively arranged at both ends; the oil circuit block 8 is connected to the oil cylinders at both ends through the diverter valve 7; The two drive rings are the first drive ring 11 and the second drive ring 5; the two pawls are the first pawl 12 and the second pawl 15; the two cylinders are the first cylinder 6 and the second cylinder. Two oil cylinders 9; the first oil cylinder 6 drives the jaws 17 to perform horizontal reciprocating motion, so that the first drive ring 11 swings, thereby making the central ratchet 4 rotate clockwise; the second oil cylinder 9 drives the jaws 17 to perform horizontal reciprocation movement, so that the second drive ring 5 swings, so that the central ratchet 4 rotates countercl...

Embodiment 3

[0023] An electro-hydraulic torque power device for an aeroengine, a central transmission gear 22 is arranged between the two drive rings; a first gear 18 and a second gear 20 are respectively arranged on both sides of the central transmission gear 22; A gear 18 is provided with a torque sensor 13; the second gear 20 is connected with a manual wrench input port 3 through a connecting rod 21, and the manual wrench input port 3 is for nut tightening or dismounting, when the required torque is small, the manual wrench input port 3 is used. The wrench is inserted into the manual wrench input port 3 to quickly tighten and disassemble the nut to achieve the purpose of improving work efficiency, and then the driving device of the hydraulic part drives the output torque; the frame 14 is provided with a display screen 1; the oil block 8 is provided with a pressure sensor 10; the angle scale 2 is connected to the side of the central ratchet 4 on the outside by screws; the pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com