Synchronous rapid replacement stainless steel container forming die

A molding die, stainless steel technology, applied in the field of stamping dies for stainless steel containers, can solve the problems affecting the bulging of stainless steel tubes, affecting the bulging speed of stainless steel round tubes, etc., to achieve the effect of convenient bulging and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

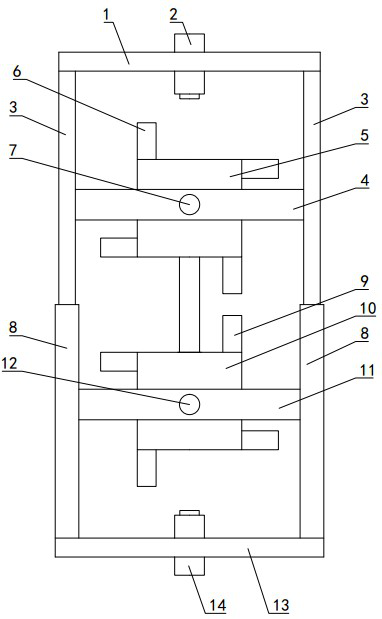

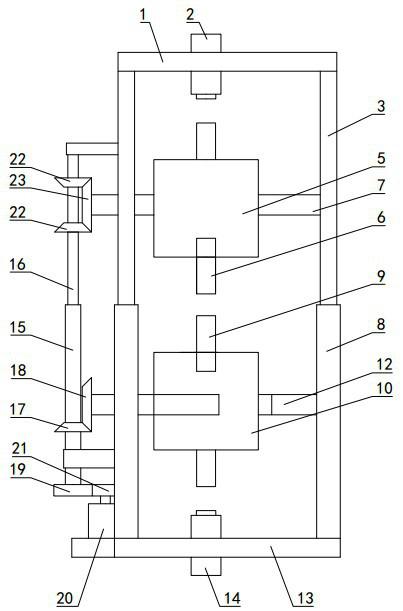

[0028] Such as Figure 1~2 Shown: This synchronous quick-change stainless steel container forming mold also includes an upper mounting frame 1, a lower mounting frame 13, a guide device, an upper mounting beam 4, and a lower mounting beam 11, and the upper mounting frame 1 and the lower mounting frame 13 are all horizontal Setting, the lower mounting frame 13 is arranged on the lower side of the upper mounting frame 1 at intervals, the upper rotating frame 5 and the lower rotating frame 10 are all arranged between the upper mounting frame 1 and the lower mounting frame 13, and the guide device is arranged on the upper mounting frame 1 and the lower mounting frame 13. Between the lower mounting frames 13, several guiding devices are evenly distributed around the upper rotating frame 5 and the lower rotating frame 10 at intervals. The upper mounting beam 4 is horizontally installed on the top of the guide device. The upper mounting beam 4 has two symmetrically arranged on both s...

Embodiment 2

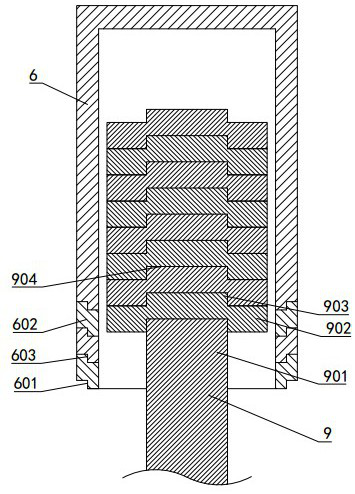

[0052] Such as Figure 6 As shown: the difference between embodiment 2 and embodiment 1 is that the upper mold cylinder 602 is spliced by several arc-shaped plates, and the connecting groove of the upper mold body is set on the inner side of the bottom of the upper mold body, surrounding the top of the upper mold cylinder 602 A docking platform matched with the connection groove is provided, the docking platform extends into the connection groove, and the docking platform and the connection groove are attracted by magnets. A hoop 31 is arranged outside the upper mold barrel 602, so that the cooperation of each lower mold barrel 602 is reliable. During use, when a certain piece of the upper mold cylinder 602 is damaged or has a large amount of wear, only the corresponding piece of the upper mold cylinder 602 can be replaced.

[0053] The lower mold main body 902 has one and only one piece, and the lower mold main body 902 is spliced by several pieces. The upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com