A device and method for forming pipe fittings based on electromagnetic attraction

A technology of attractiveness and pipe fittings, which is applied in the field of forming and processing of metal pipe fittings, can solve problems such as limited application scenarios and difficulties in bulging and forming of small pipe fittings, and achieve the effects of reducing production costs, solving difficult problems, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

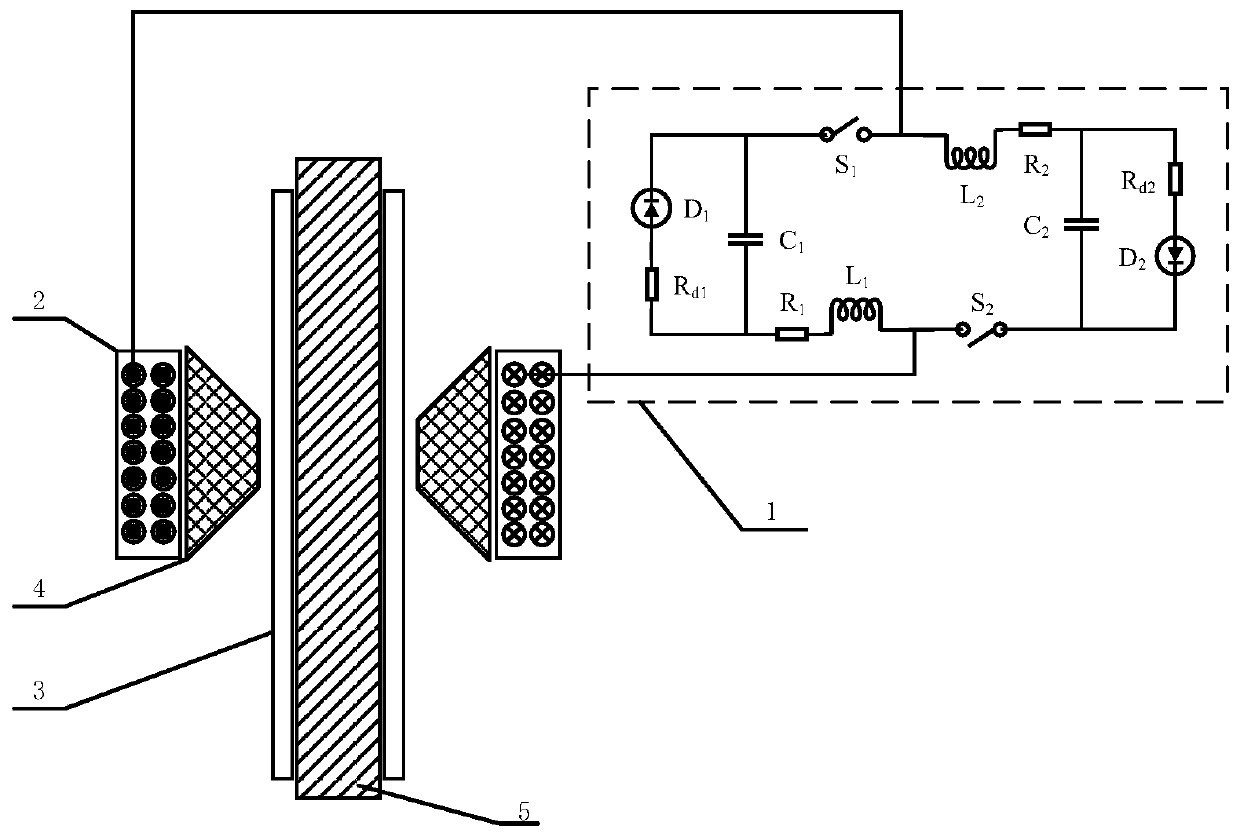

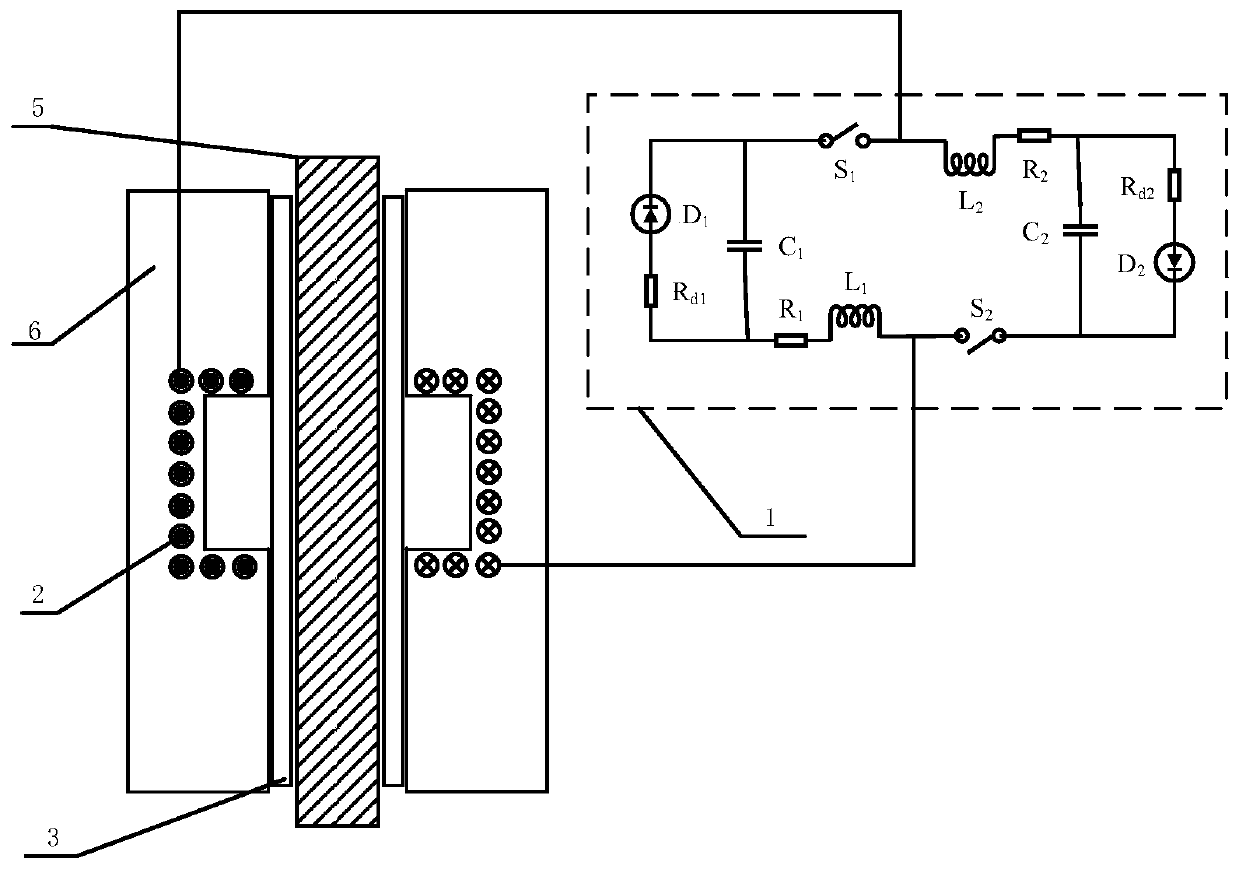

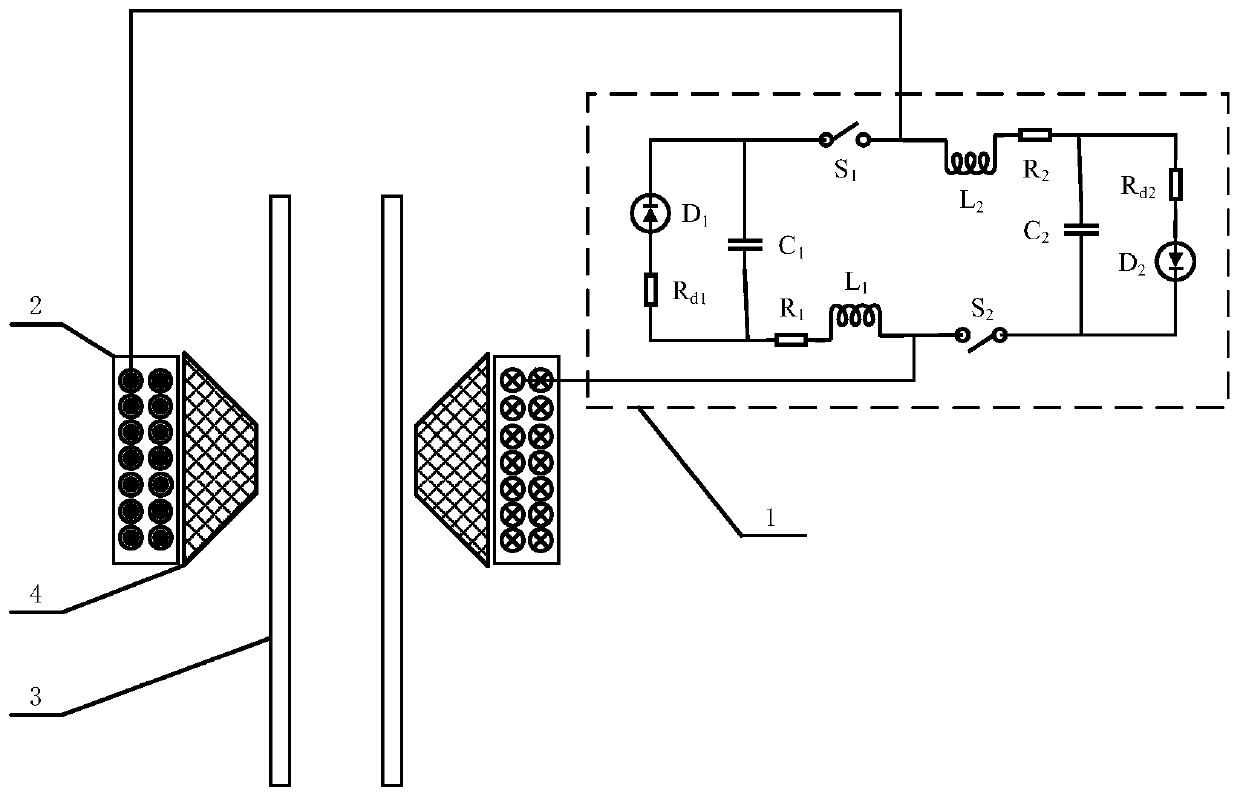

[0028] The present invention provides a tube forming device and method based on electromagnetic attraction. The specific technical solutions are as follows:

[0029] A pipe forming device based on electromagnetic attraction. The end of the metal pipe 3 is fixed by a mechanical structure or a hydraulic structure. A solenoid forming coil 2 is sleeved on the metal tube 3 to be formed, and fixed by a mechanical structure or a hydraulic structure to leave a certain forming gap.

[0030] The fixing method of mechanical structure or hydraulic structure is as follows:

[0031] A positioning ring is placed between the outer wall of the metal tube 3 and the inner wall of the solenoid forming coil 2 to make the two coaxial and to align the center area of the solenoid forming coil 2 with the area to be formed of the metal tube wall 3. At the same time, a hydraulic press is used to restrain the entire device at the end to prevent the device from shaking in the axial direction.

[0032] A wide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com