Circumferential mechanical property testing device of valve-model type thin-wall tube

A technology for testing equipment and pipe fittings, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the circumferential mechanical properties of the pipe fittings cannot be accurately represented, and the small-sized thin-walled pipe fittings cannot be cut and rolled. Achieve the effect of improving engineering reliability, improving test accuracy and eliminating test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

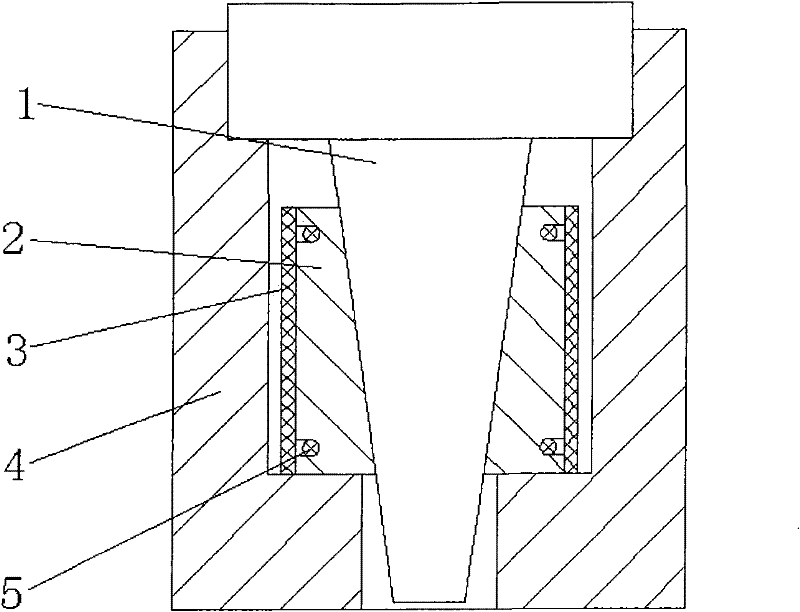

[0019] This embodiment is a device for testing the circumferential mechanical properties of 7050 high-strength aluminum alloy pipe fittings. The specific size of the applicable test piece is 20mm×1mm, height is 20mm.

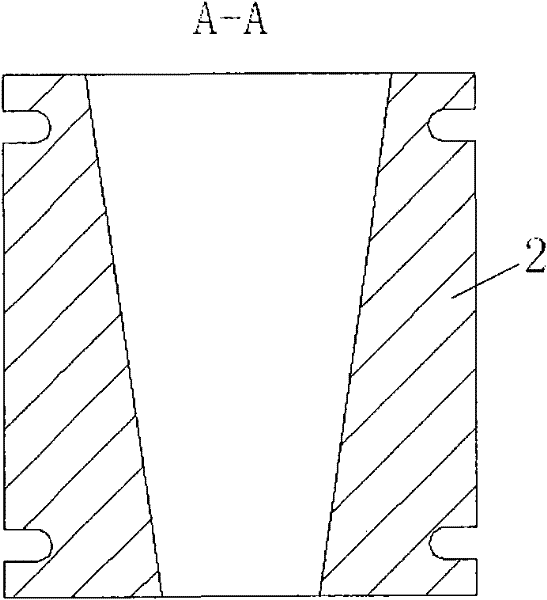

[0020] This embodiment includes a conical indenter 1 , a flap mold 2 and a protective sleeve 4 . Both the conical indenter 1 and the valve mold 2 are made of Cr12Mo1V1 steel, and the protective sleeve 4 is made of 45# steel. The valve mold 2 is placed in the tested tube 3, and there is a clearance fit between the two. The conical indenter 1 is located in the valve mold 2 and placed in the protective sleeve 4 together. There is a clearance fit between the maximum inner diameter of the protective sleeve and the outer diameter of the platform of the conical indenter.

[0021] The conical indenter 1 is a body of revolution, and its profile is "T" shape. One end of the conical indenter 1 is a matching platform in contact with the indenter of the mechanical prop...

Embodiment 2

[0026] This embodiment is a device for testing the circumferential mechanical properties of 7050 high-strength aluminum alloy pipe fittings. The specific size of the applicable test piece is 22mm×1mm, height 20mm.

[0027] This embodiment includes a conical indenter 1 , a flap mold 2 and a protective sleeve 4 . Both the conical indenter 1 and the valve mold 2 are made of Cr12Mo1V1 steel, and the protective sleeve 4 is made of 45# steel. The valve mold 2 is placed in the tested tube 3, and there is a clearance fit between the two. The conical indenter 1 is located in the valve mold 2 and placed in the protective sleeve 4 together. There is a clearance fit between the maximum inner diameter of the protective sleeve and the outer diameter of the platform of the conical indenter.

[0028] The conical indenter 1 is a body of revolution, and its profile is "T" shape. One end of the conical indenter 1 is a matching platform in contact with the indenter of the mechanical propert...

Embodiment 3

[0033] This embodiment is a device for testing the circumferential mechanical properties of 69111 high-strength steel pipe fittings. The specific size of the applicable test piece is 25mm×1mm, height 22mm.

[0034] This embodiment includes a conical indenter 1 , a flap mold 2 and a protective sleeve 4 . Both the conical indenter 1 and the valve mold 2 are made of Cr12Mo1V1 steel, and the protective sleeve 4 is made of 45# steel. The valve mold 2 is placed in the tested tube 3, and there is a clearance fit between the two. The conical indenter 1 is located in the valve mold 2 and placed in the protective sleeve 4 together. There is a clearance fit between the maximum inner diameter of the protective sleeve and the outer diameter of the platform of the conical indenter.

[0035] The conical indenter 1 is a body of revolution, and its profile is "T" shape. One end of the conical indenter 1 is a matching platform in contact with the indenter of the mechanical properties of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com