Rail guided vehicle (RGV) matching device for intelligent automatic striding of travelling crane

A small car and automatic technology, applied in the direction of lifting devices, trucks, transport buses, etc., can solve the problems of low efficiency and high efficiency, and achieve the effect of increasing the carrying area and expanding the storage height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

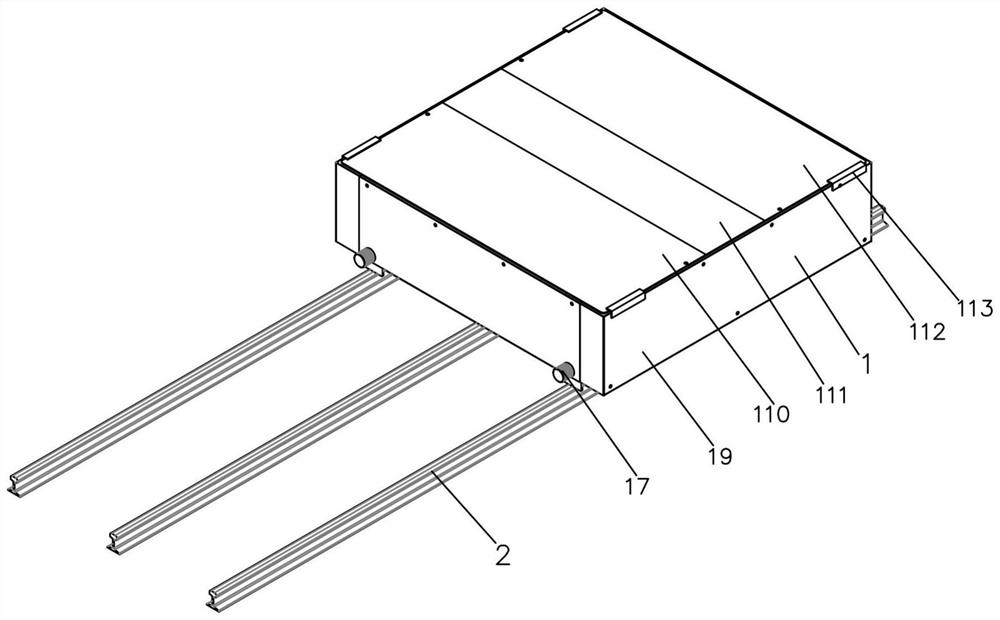

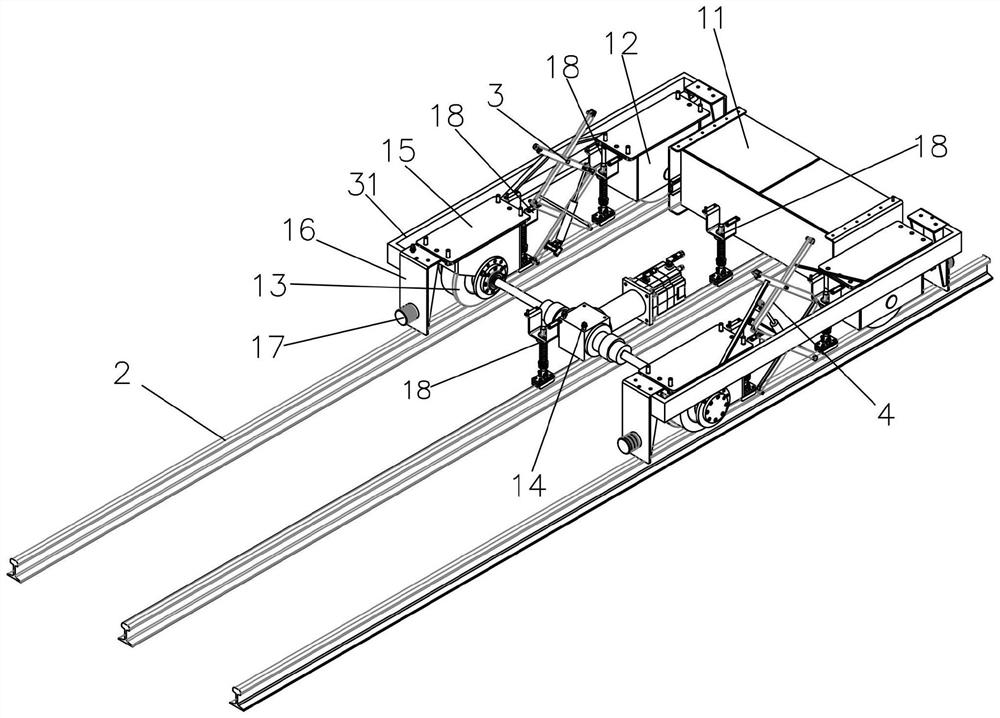

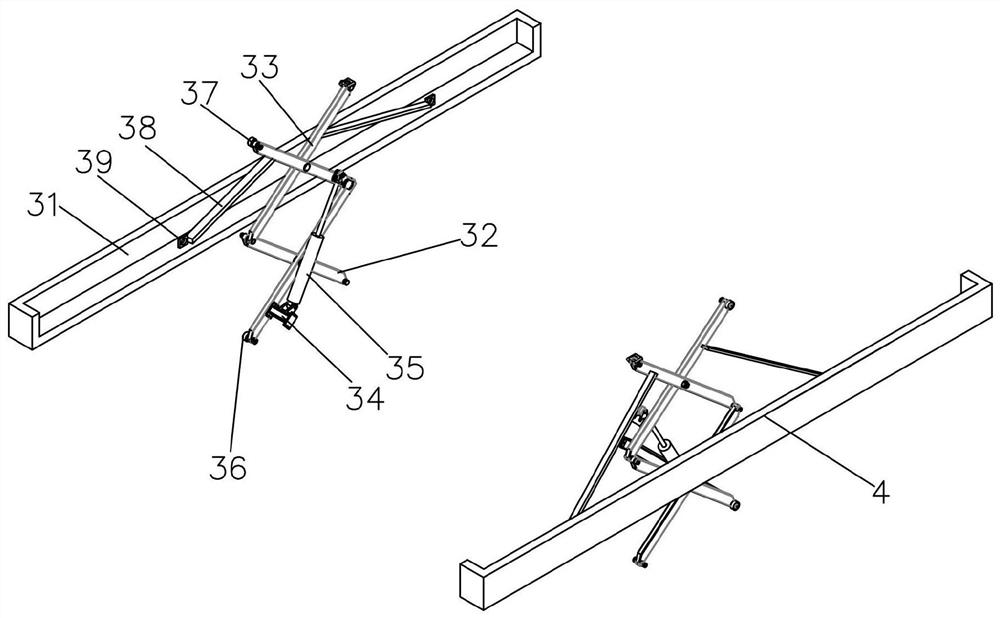

[0018] Embodiment: a kind of RGV trolley corollary device for intelligent automatic over-span of driving, such as Figure 1-Figure 4 As shown, it includes the RGV trolley body 1 and the track 2, the RGV trolley body 1 is slidably connected to the top of the track 2, the rear side of the RGV trolley body 1 is provided with a first lifting device 3, and the front side of the RGV trolley body 1 is provided with a The second lifting device 4, the tops of the first lifting device 3 and the second lifting device 4 are all provided with a lifting plate 111, and the lifting plate 111 is inserted on the top of the RGV trolley body 1 and is parallel to the top. Both sides are provided with a first limiting seat 1111 .

[0019] The RGV trolley body 1 includes a control box 11, two passive wheel frames 12 and two active wheel frames 13. On the left side of the passive wheel frame 12, two active wheel frames 13 facing each other are provided with a reduction motor unit 14, and the two pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com