Laser marking equipment for modified heavy-duty motorcycle nameplate

A technology of laser marking equipment and motorcycles, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of manpower and time, low work efficiency, etc., achieve good results, reduce the trouble of maintenance and oiling, Easy access to collected effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

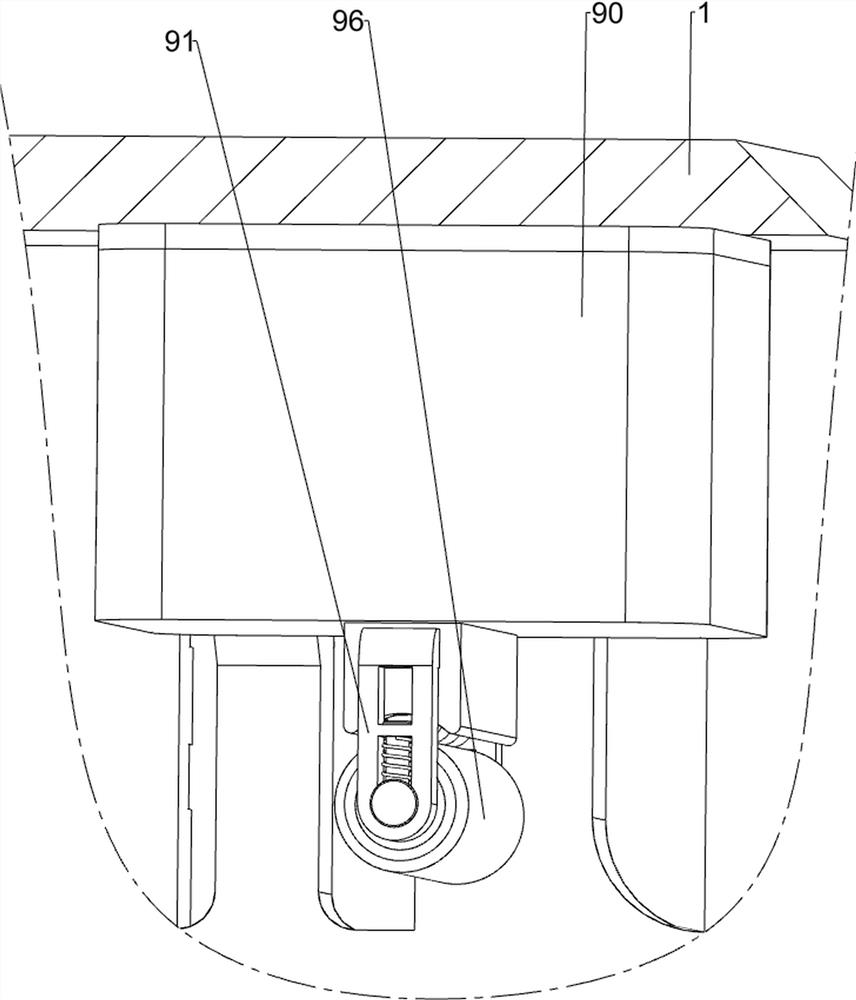

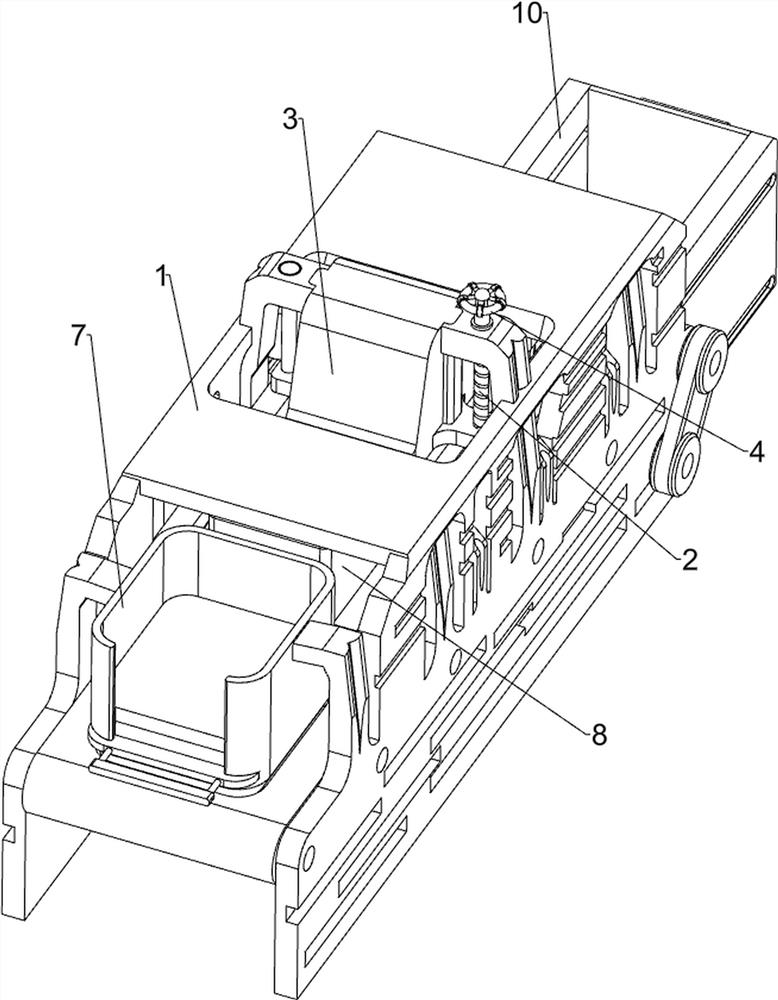

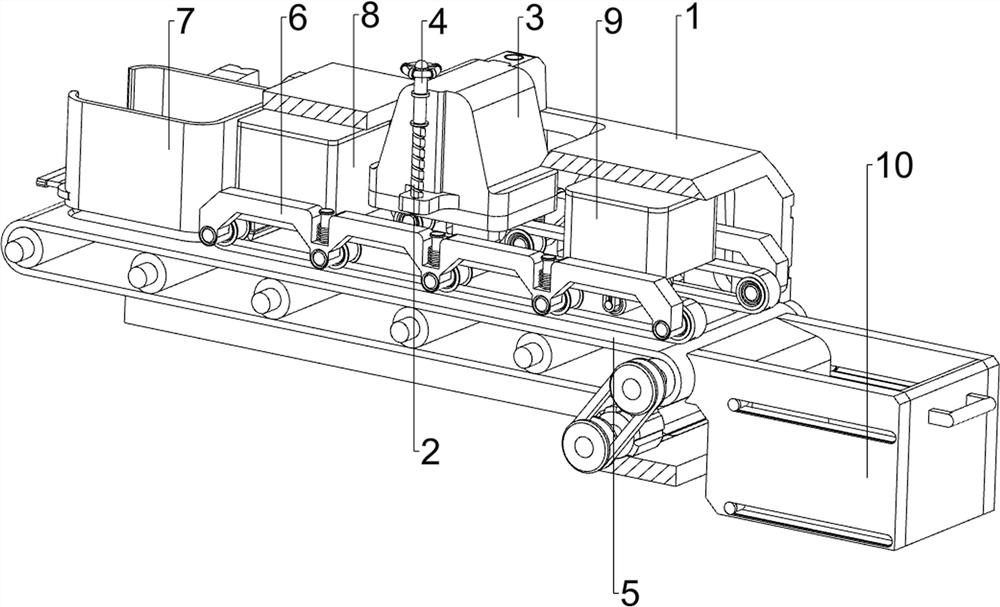

[0037] A modified heavy-duty motorcycle nameplate laser marking equipment, such as Figure 1-7 As shown, it includes a mounting bracket 1, a screw 2, a marking device 3, a handle 4, a transmission mechanism 5 and a clamping mechanism 6. The right side of the middle part of the mounting bracket 1 is connected to the screw 2 in a rotating manner, and the middle part of the mounting bracket 1 is sliding. A marking device 3 is connected, and the marking device 3 is connected with the screw rod 2 through threads, the upper side of the screw rod 2 is welded with a handle 4, the inner side of the mounting bracket 1 is provided with a transmission mechanism 5, and the inner side of the mounting bracket 1 is provided with a clamping mechanism 6.

[0038] When it is necessary to carry out laser marking on the modified heavy-duty motorcycle name cover, the handle 4 can be controlled to drive the screw 2 to rotate according to the thickness of the modified heavy-duty motorcycle name cover...

Embodiment 2

[0043] On the basis of Example 1, such as image 3 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a feeding mechanism 7 is also included, and the feeding mechanism 7 includes a material storage frame 70, a baffle plate 71 and a first handle 72, the upper front side of the mounting bracket 1 is connected with a material storage frame 70, and the bottom of the material storage frame 70 A baffle 71 is slidably connected, and a first handle 72 is connected to the front side of the baffle 71 .

[0044] When it is necessary to carry out laser marking on the modified heavy-duty motorcycle nameplate, the modified heavy-duty motorcycle nameplate is stacked in the storage frame 70, and the modified heavy-duty motorcycle nameplate will be blocked by the baffle 71. When the modified heavy-duty motorcycle nameplate needs to be placed When on the conveyor belt 56, control the first handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com