Multi-station laser marking machine for semiconductor intelligent manufacturing

A laser marking machine and intelligent manufacturing technology, applied in the field of laser marking machines, can solve the problems of untimely marking and reducing equipment work efficiency, and achieve the effect of facilitating processing and preventing marking errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

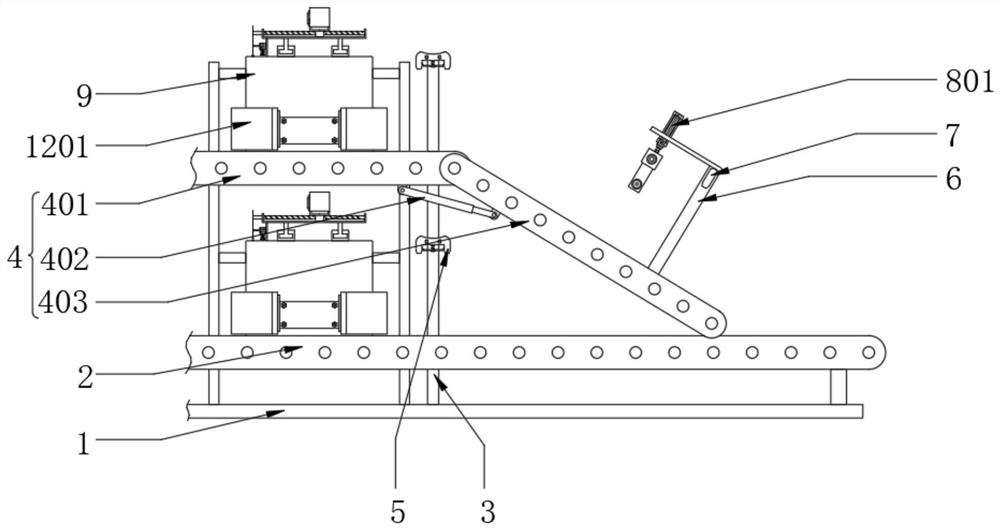

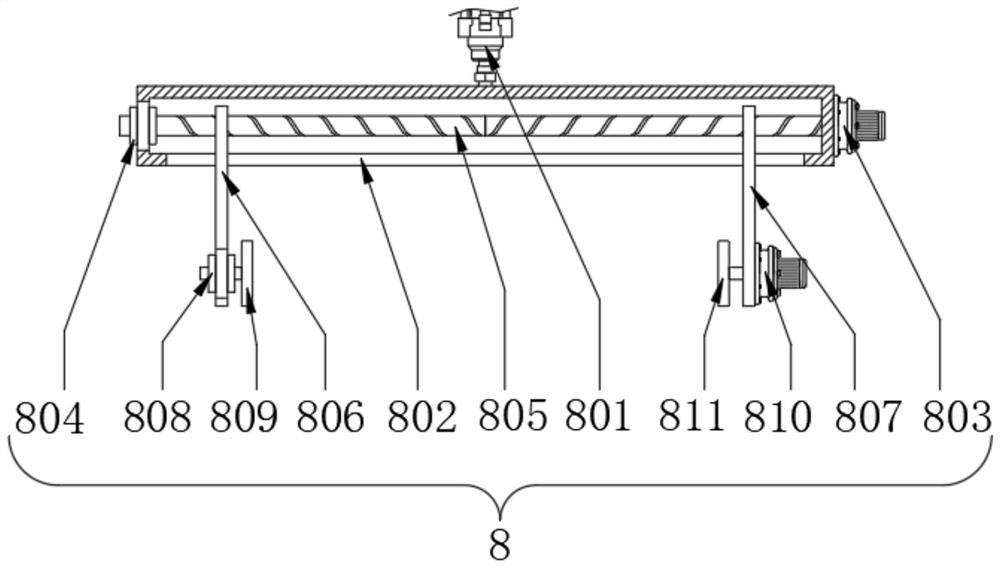

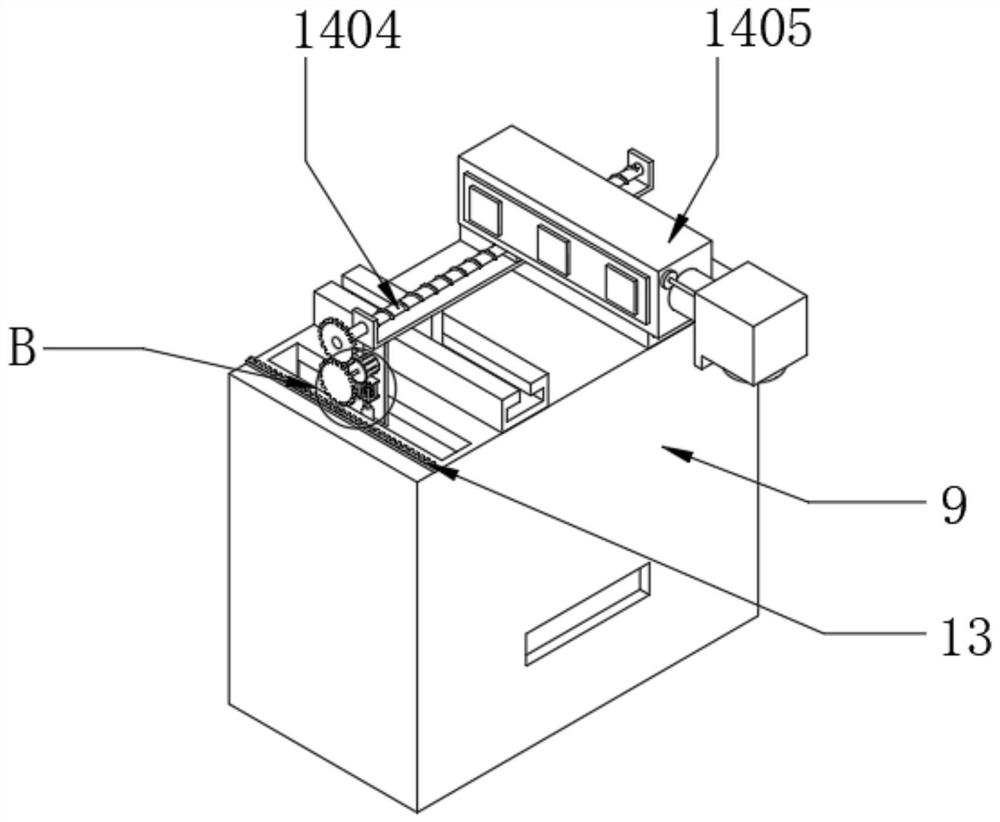

[0031] like Figure 1 to Figure 8 As shown, the present invention provides a technical solution: a multi-station laser marking machine for semiconductor intelligent manufacturing, including a base 1 and a support base 6, and a first roller transmission belt 2 and a Support 3, and the middle end and the upper end of support 3 are equipped with the first scanner 5, the upper end of the first roller transmission belt 2 is provided with layered assembly 4, and layered assembly 4 includes the second roller transmission belt 401, the first electric pusher The rod 402 and the third roller transmission belt 403, the lower end of the second roller transmission belt 401 is connected with the first electric push rod 402, and the right end of the second roller transmission belt 401 is movably connected with the third roller transmission belt 403, the support base 6 is located in the layered assembly 4 The upper end of the upper wall, and the lower end of the upper wall of the support seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com