Microswitch assembling equipment

A technology for micro-switches and assembling equipment, applied in electrical switches, assembling machines, metal processing equipment, etc., can solve the problems of reduced production efficiency, long time consumption, dislocation of moving pieces, etc., and achieves the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

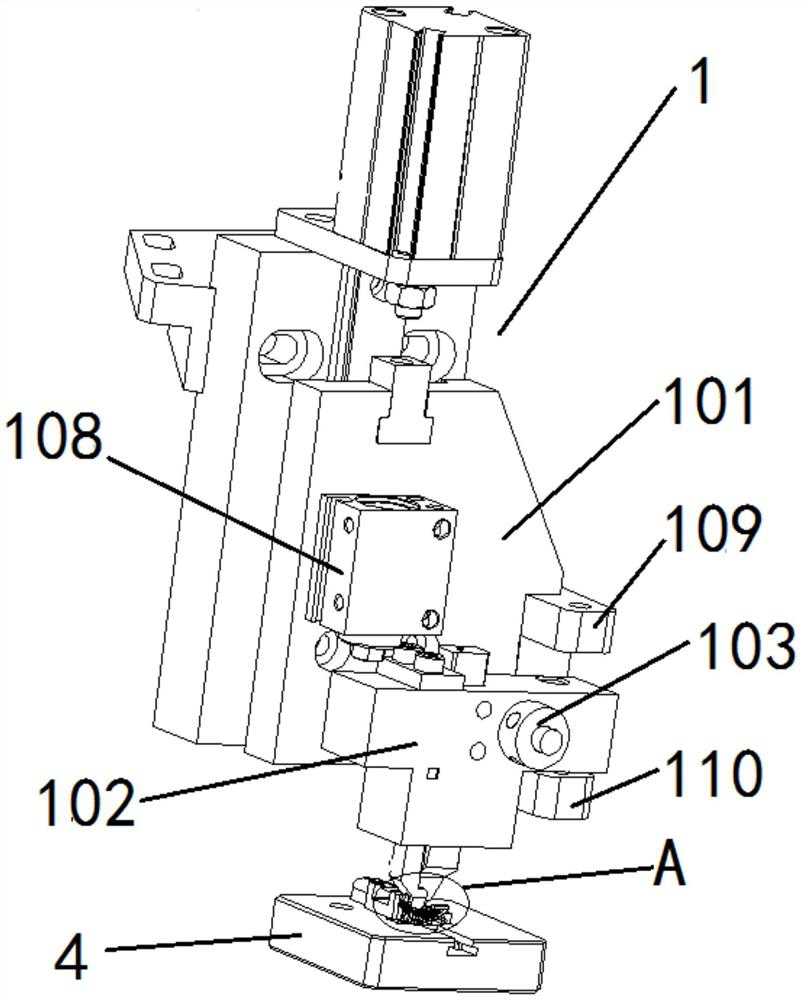

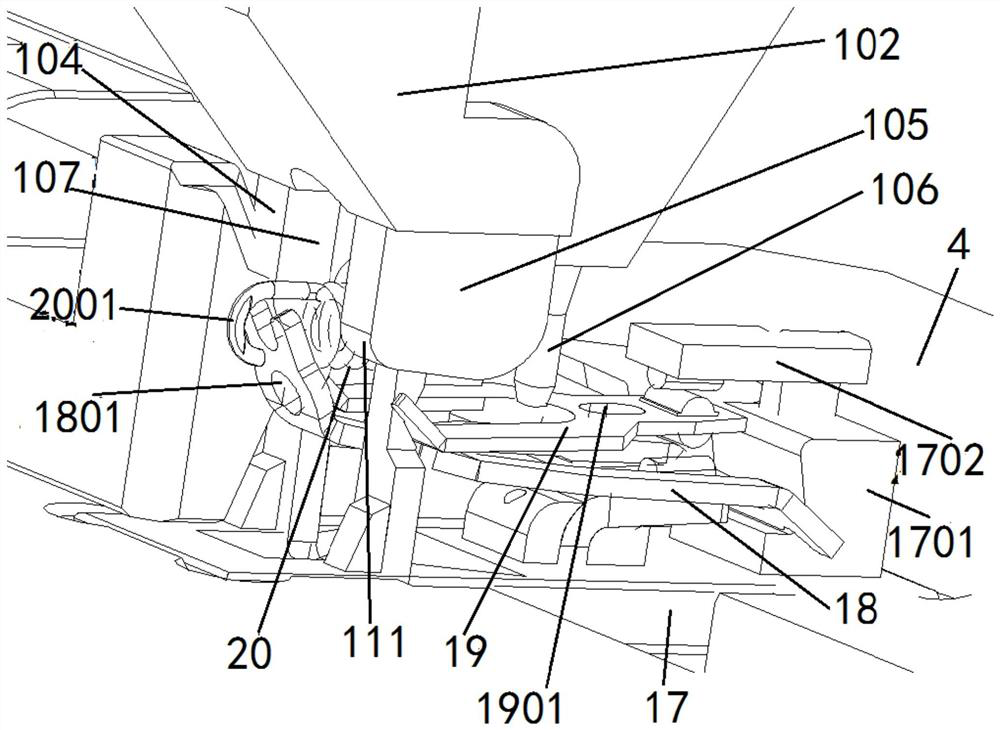

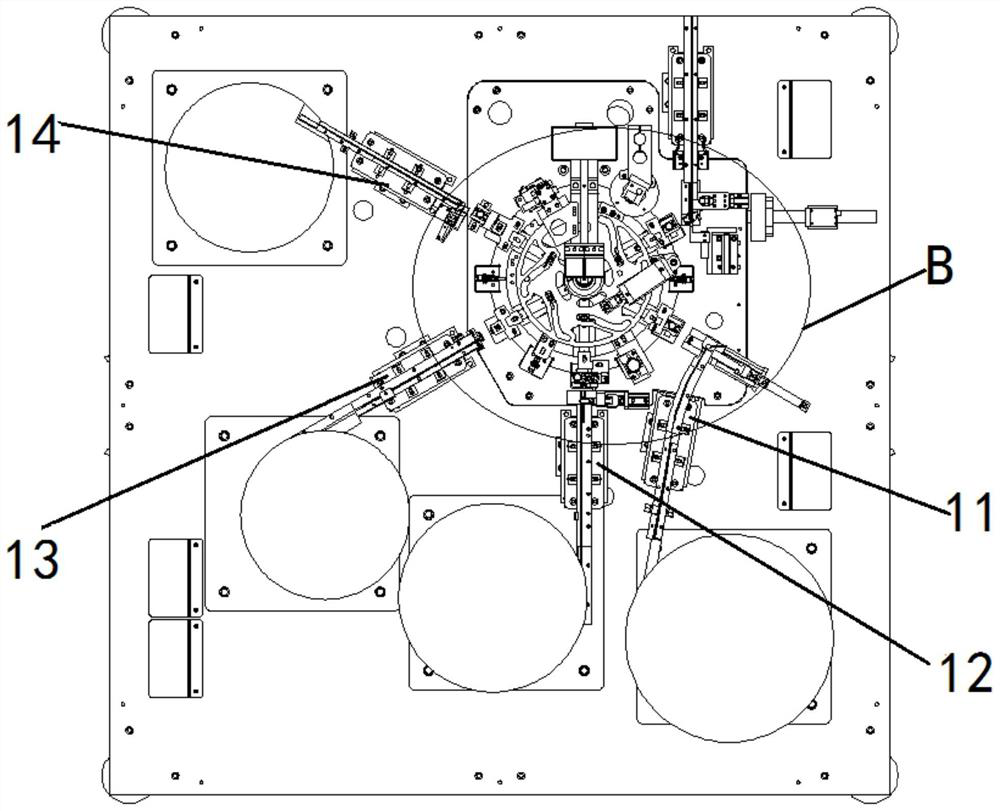

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention, but this does not constitute a limitation to the protection scope of the present invention.

[0033] In the present invention, for a clearer description, the following description is made: the observer faces the attached figure 1 For observation, the left side of the observer is set as left, the right side of the observer is set as right, the front of the observer is set as front, the back of the observer is set as back, the top of the observer is set as up, and the bottom of the observer is set as bottom. It should be pointed out in the text The terms "front end", "rear end", "left side", "right side", "middle", "above", "below", etc. indicating the orientation or positional relationship are based on the orientation or positional relationship set in the drawings ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap