Power cable erection conveying device having clamping mechanism

A technology of power cables and transmission devices, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to fix cables and inconvenient adjustment of cable heights, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

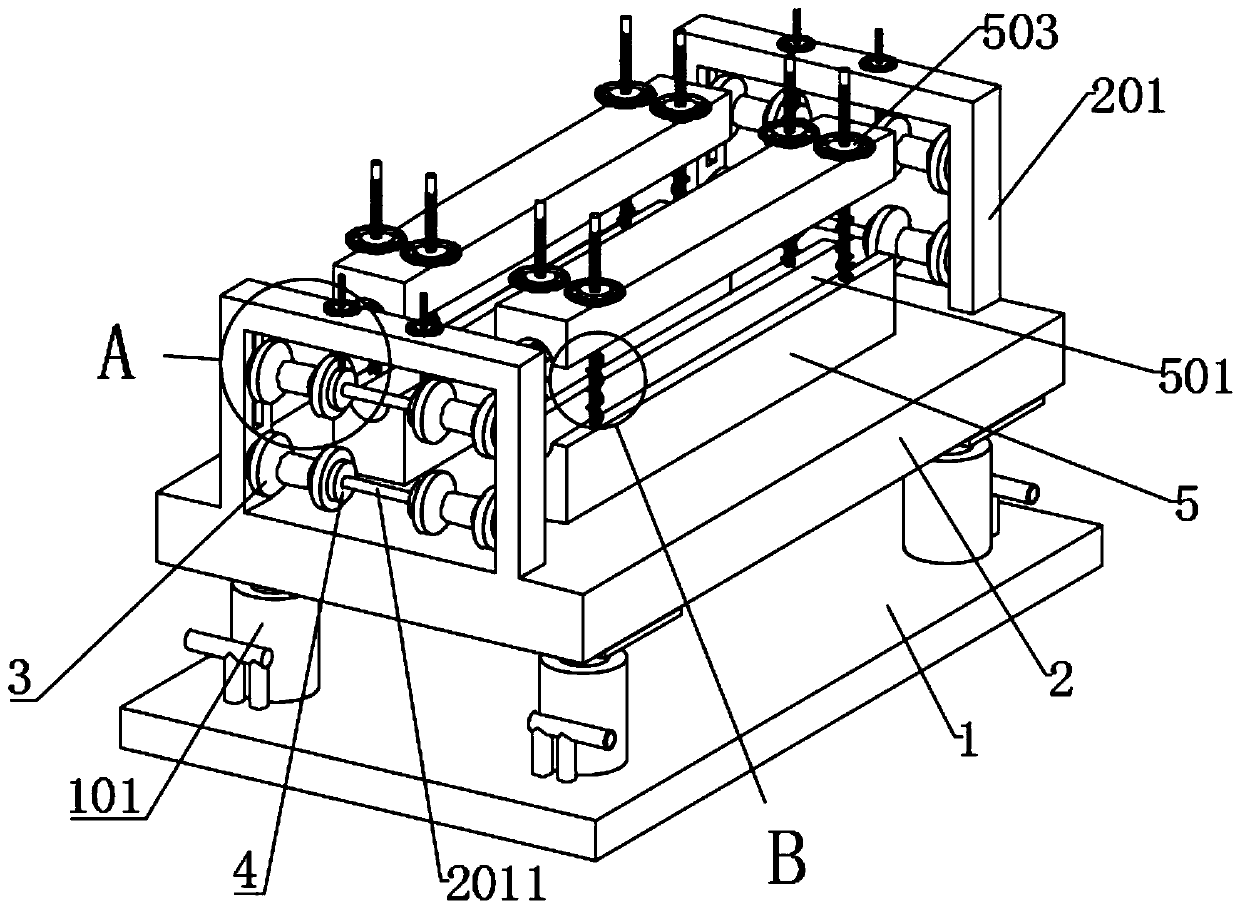

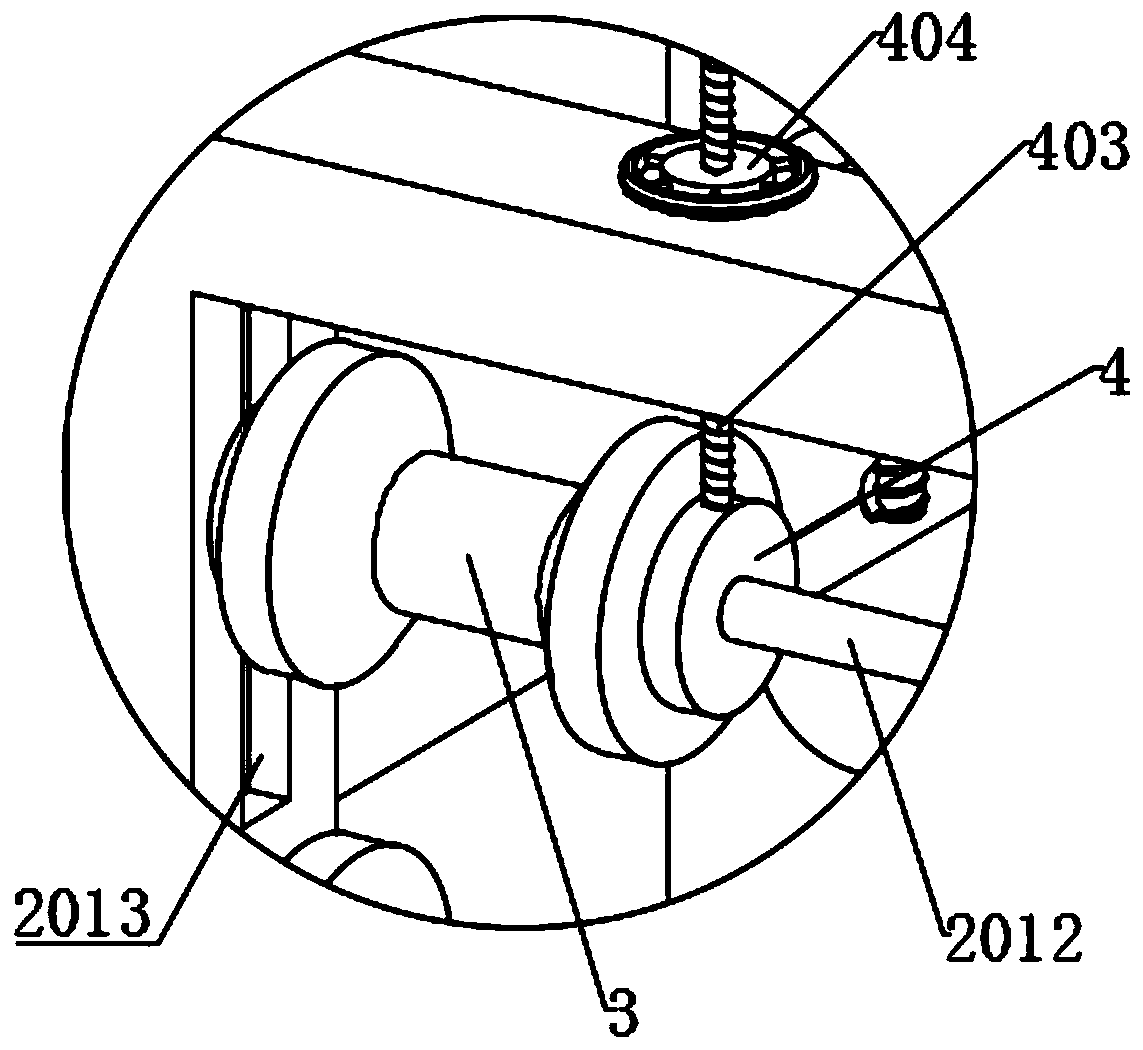

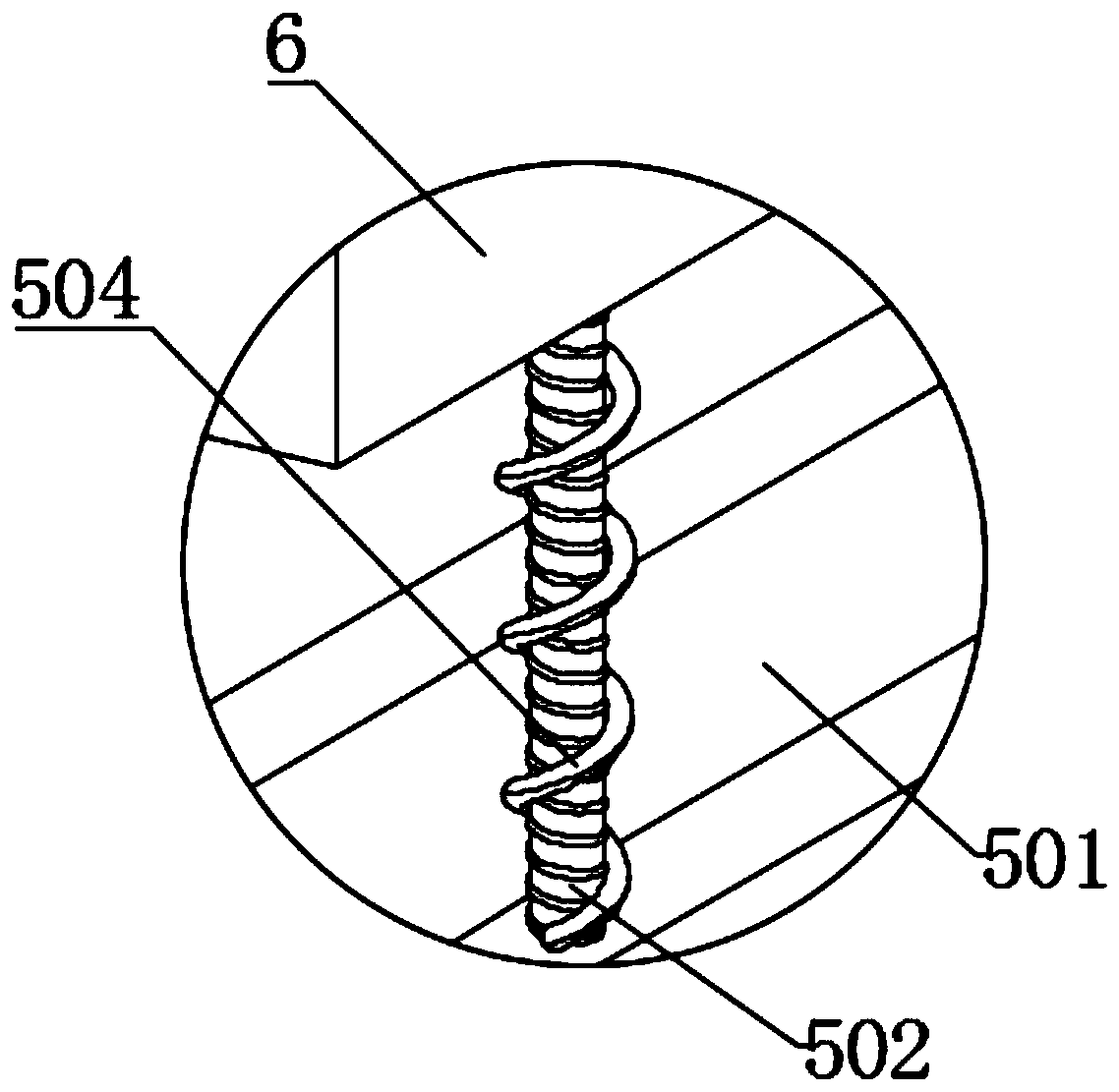

[0033] as attached figure 1 To attach Figure 7 Shown:

[0034] The present invention provides a power cable erecting and conveying device with a clamping mechanism, including a bottom plate 1, a jack 101, an adjusting support plate 2, a square frame 201, a fixing cross bar 2011, an adjusting cross bar 2012, an adjusting chute 2013, and a pulley 3 , through hole 301, bearing 302, limiting circular plate 4, internal thread hole 401, ball 402, adjusting screw A403, adjusting hand wheel A404, lower bar 5, arc groove 501, adjusting screw B502, adjusting hand wheel B503 , spring 504 and upper strip 6; jacks 101 are fixedly installed on the top four ends of the bottom plate 1, and the top of the jack 101 is screwed into the bottom end surface of the adjustment brace 2 by screws, and the adjustment brace 2 Both ends are provided with a square frame 201, and the inner lower end of the square frame 201 is welded with a fixed cross bar 2011, and both ends of the fixed cross bar 2011 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap