Opposite-pulling electricity-leading type universal hanging tool used in screw head electroplating process

An electroplating process and screw head technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of increasing labor intensity, increasing electroplating costs, wasting energy, resources and efficiency, etc., to avoid manual labor, reduce electroplating costs, and ensure electroplating effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

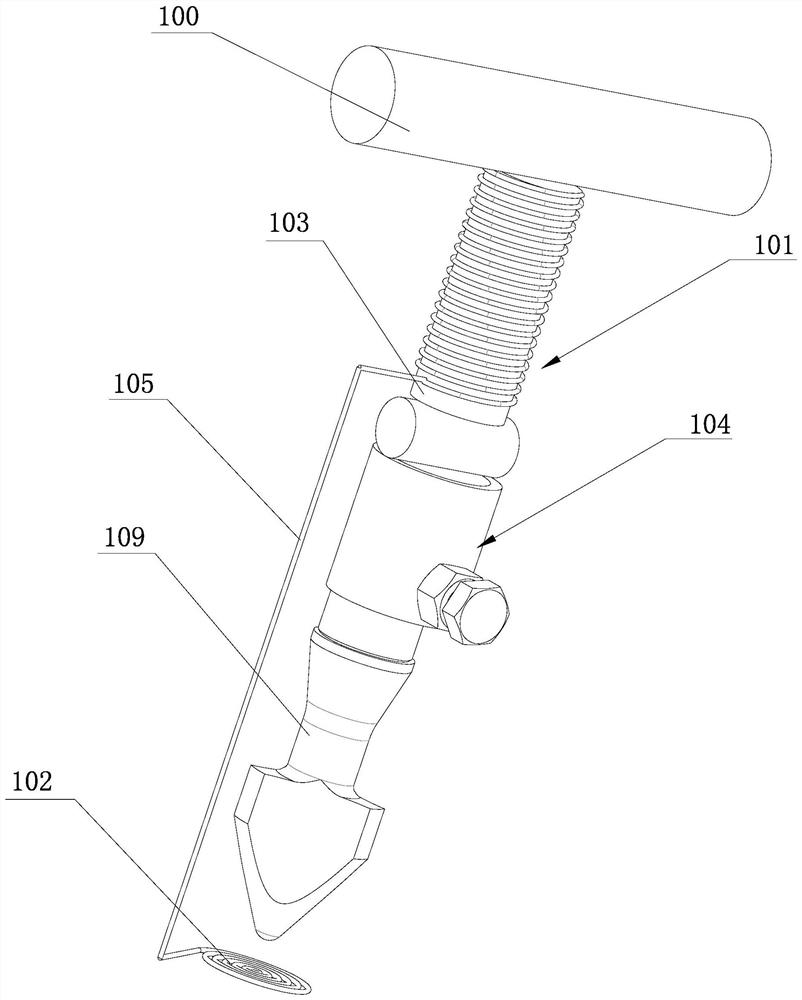

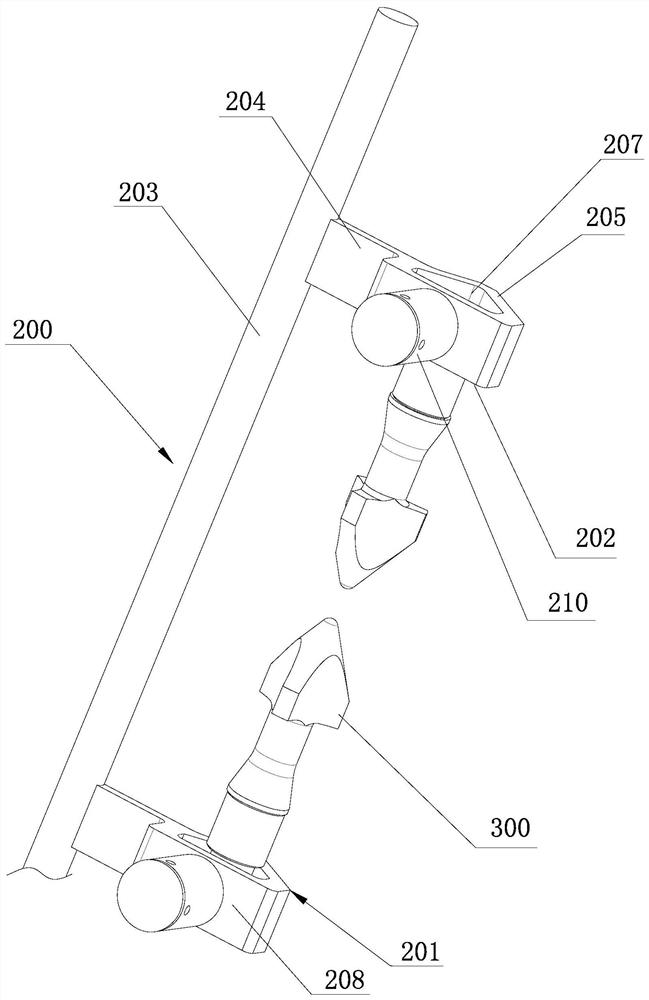

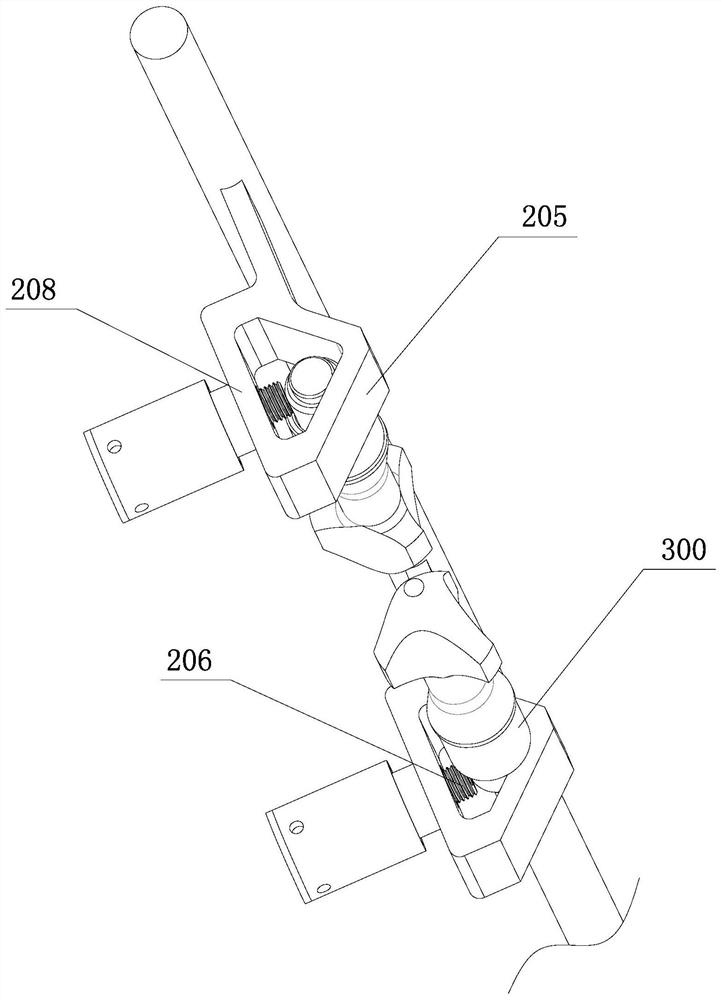

[0022] Following the principle of electroplating technology, the current needs to run smoothly during the electroplating process, which requires cathode pulling, that is, the corresponding cathode of the product is essential, so it is impossible to cancel the cathode to avoid the disadvantages of the cathode setting in the traditional electroplating conductive rack , in order to ensure compliance with the basic principles of electroplating and to break through the corresponding technical bottlenecks, the present invention proposes a pair-pull electric universal hanger used in the electroplating process of the screw head, such as figure 2 , image 3 with Figure 4 As shown, it includes a hanger unit 200. The hanger unit 200 includes two mirror-symmetrically distributed hangers 201. The opposite end of the two hangers 201 is the screw head ext...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap