Wire cutting and twisting device and method for welding wire of signal machine room

A technology of welding wire and wire pressing device, applied in the field of automation, can solve problems such as error-prone, different wiring connection stability, and boring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

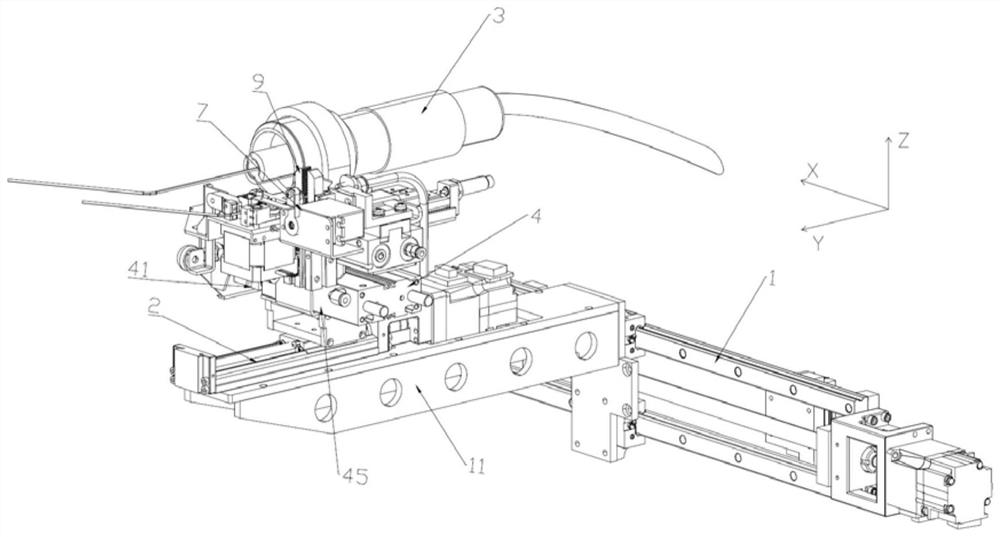

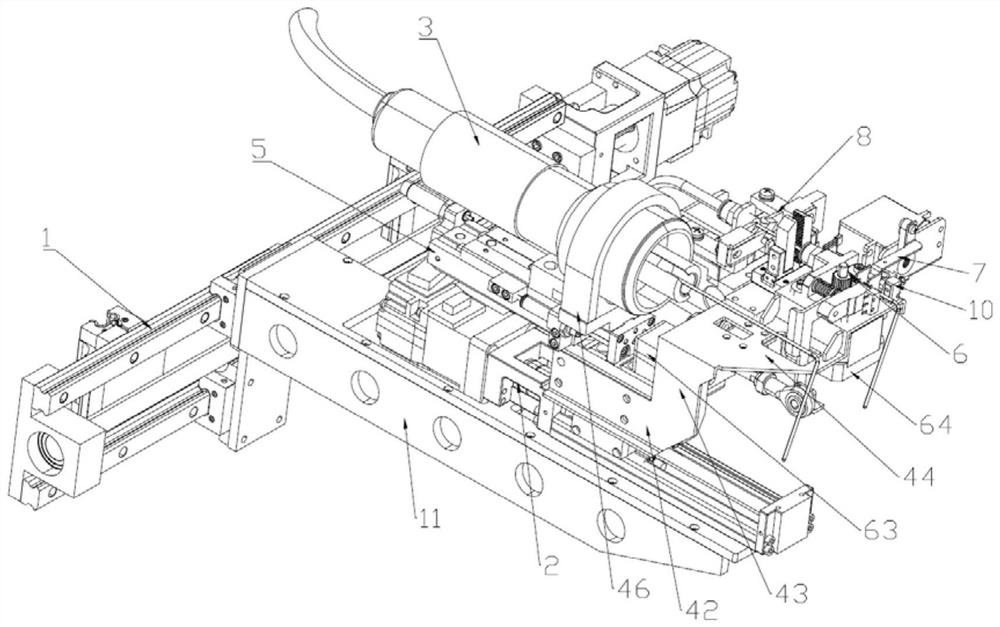

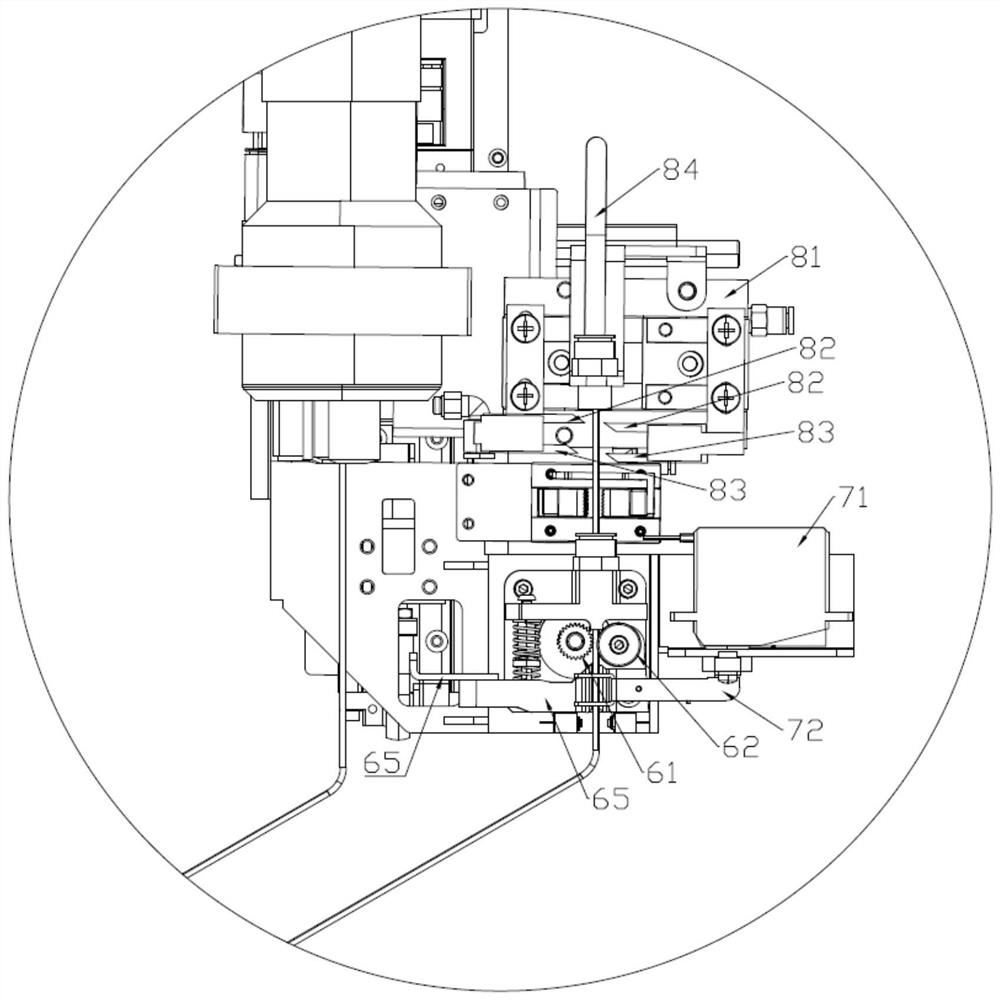

[0039] Such as figure 1 , 2As shown, a wire cutting and twisting device 3 for welding wires in a signal room includes a first traverse device 1, a base 11, a second traverse device 2, a wire twisting device 3, a third traverse device 4, a Four traversing devices 5, wire feeding devices 6, thread cutting devices 8 and thread crimping devices 7; wherein the base 11 is arranged on the first traversing device 1, and the first traversing device 1 can drive the base 11 to move in the X-axis direction ; The second traverse device 2 is fixedly arranged on the base 11; the third traverse device 4 is arranged on the second traverse device 2, and the second traverse device 2 can drive the third traverse device 4 to move in the Y-axis direction The third traversing device 4 includes a third movable part 41 and a third fixed part 45, wherein the third movable part 41 can move in the X-axis direction; part 41, the fourth traverse device 5 and the thread cutting device 8 are all arranged o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap