Novel yarn tension regulator

A yarn tension and tension adjustment technology, applied in the field of textile weaving, can solve the problems of inconvenient operation, unstable output tension, high cost, etc., and achieve the effect of reducing cost and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

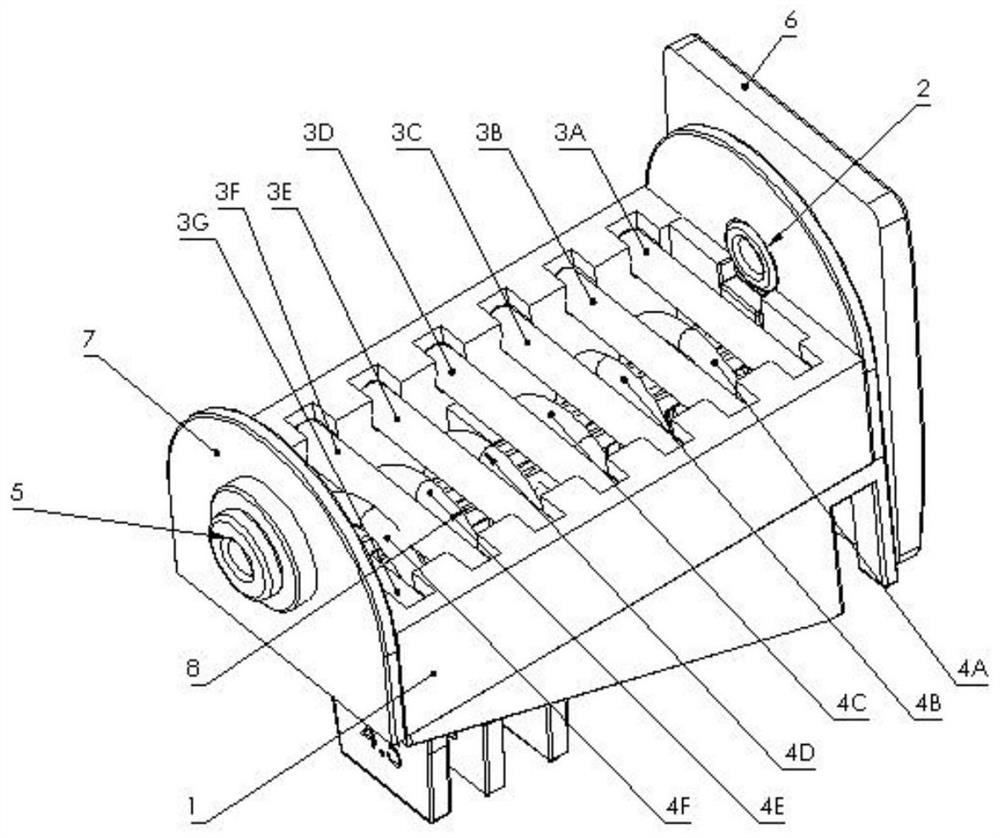

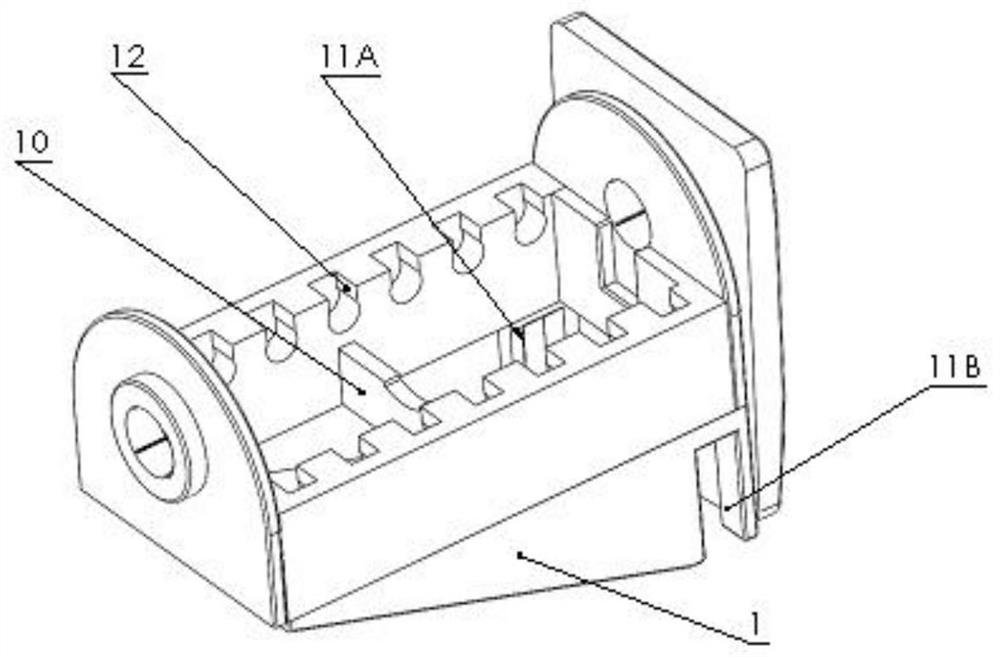

[0044] like figure 1 As shown, a tension disc 6 is provided at the yarn entrance to prevent the yarn from being entangled in the yarn tension regulator and causing tight yarn. After the yarn is unwound from the bobbin, the yarn is in a tension-free state. In this state, under the action of the internal stress of the yarn, some yarns will twist back, and the twist will produce twist-like knots. Knot, this knot is easy to hook on the yarn tension regulator, preventing the yarn from continuing to enter the porcelain eye 2 of the yarn inlet, resulting in tight yarn. The function of the tension disc 6 is to straighten the yarn before the yarn enters the yarn tension regulator, so as to prevent the yarn from catching the parts of the yarn tension regulator when the yarn is twisted back, causing the problem of yarn tightness; The ceramic eye 2 in the middl...

PUM

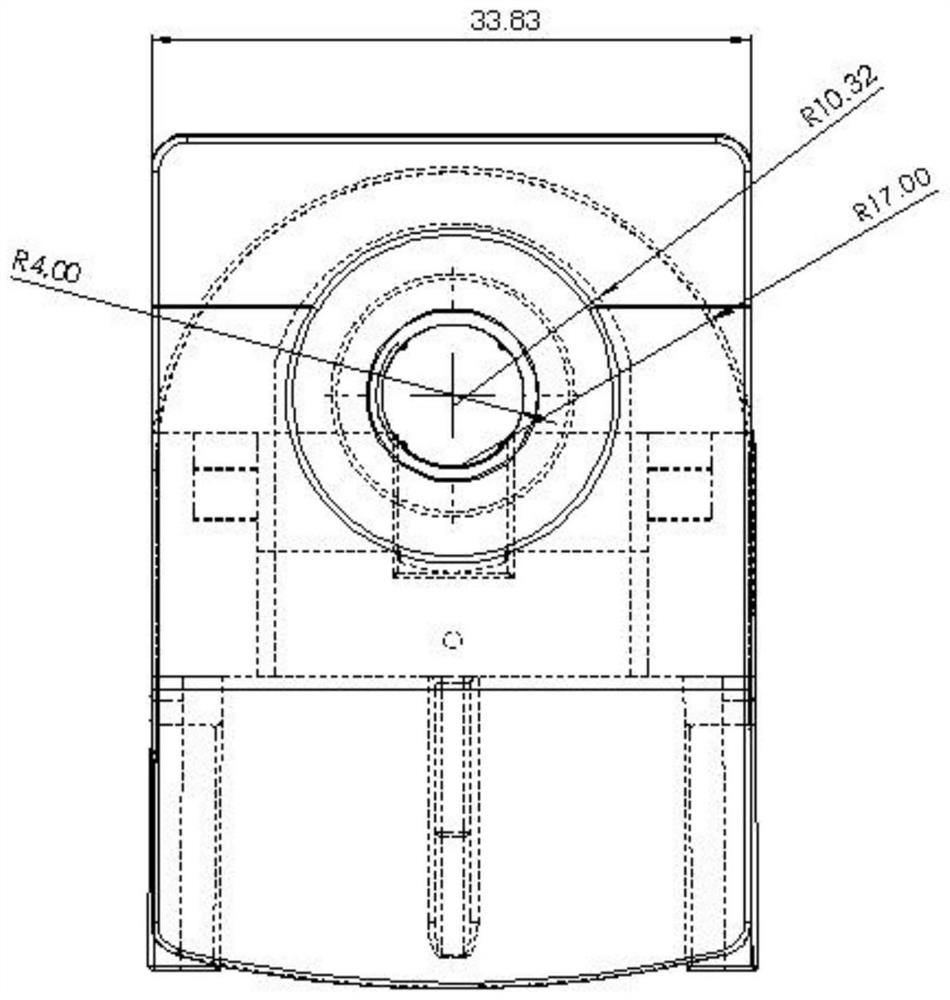

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com