Loop heat pipe

A heat pipe and loop technology, applied in the field of loop heat pipes, can solve problems such as difficult heat dissipation and increased heat generation of heating components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

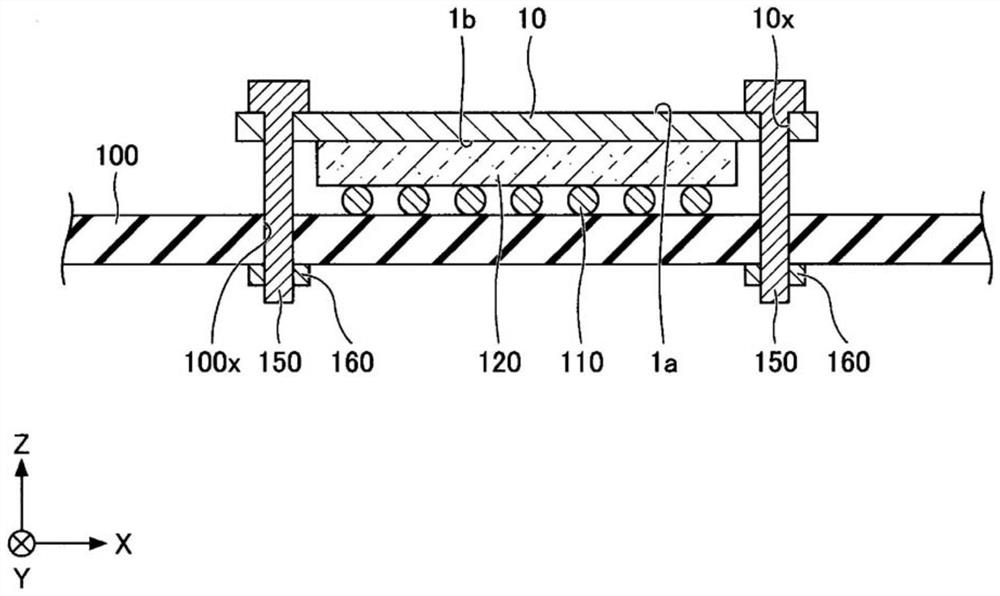

[0033] [Structure of the loop heat pipe of the first embodiment]

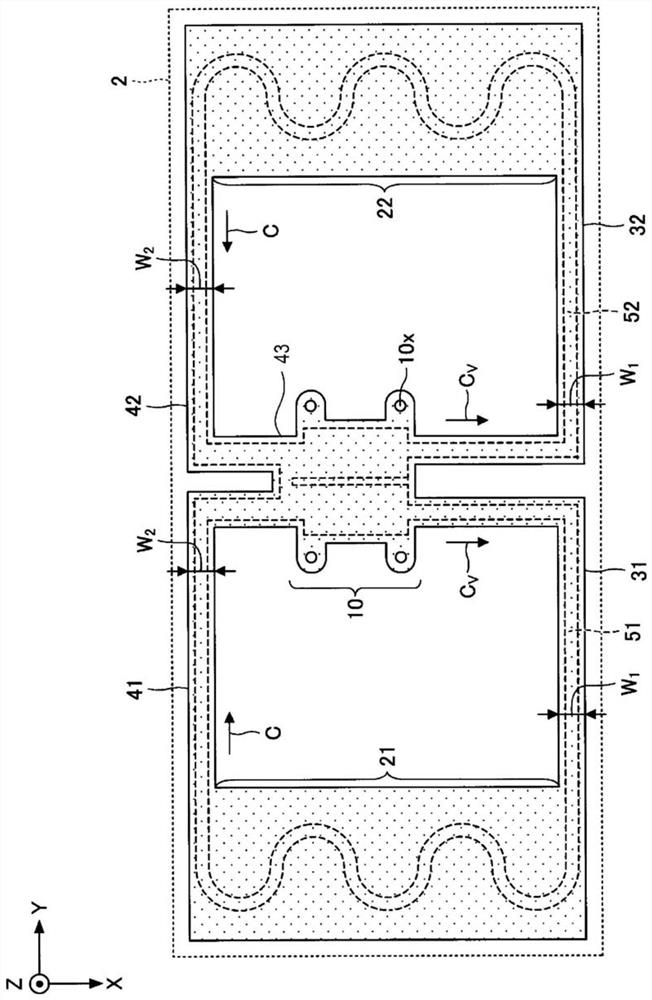

[0034] First, the structure of the loop heat pipe according to the first embodiment will be described. figure 1 is a schematic plan view illustrating the loop-type heat pipe according to the first embodiment.

[0035] refer to figure 1 , the loop heat pipe 1 includes: an evaporator 10, a first condenser 21, a second condenser 22, a first vapor pipe 31, a second vapor pipe 32, a first liquid pipe 41, a second liquid pipe 42 and a connecting portion 43. The loop heat pipe 1 can be accommodated, for example, in portable electronic devices 2 such as smartphones and tablet terminals.

[0036] In the loop heat pipe 1 , the evaporator 10 has a function of evaporating the working fluid C to generate the vapor Cv. Both the first condenser 21 and the second condenser 22 have a function of condensing the vapor Cv of the working fluid C. The first liquid pipe 41 is connected to the first condenser 21 . The second liq...

no. 2 example

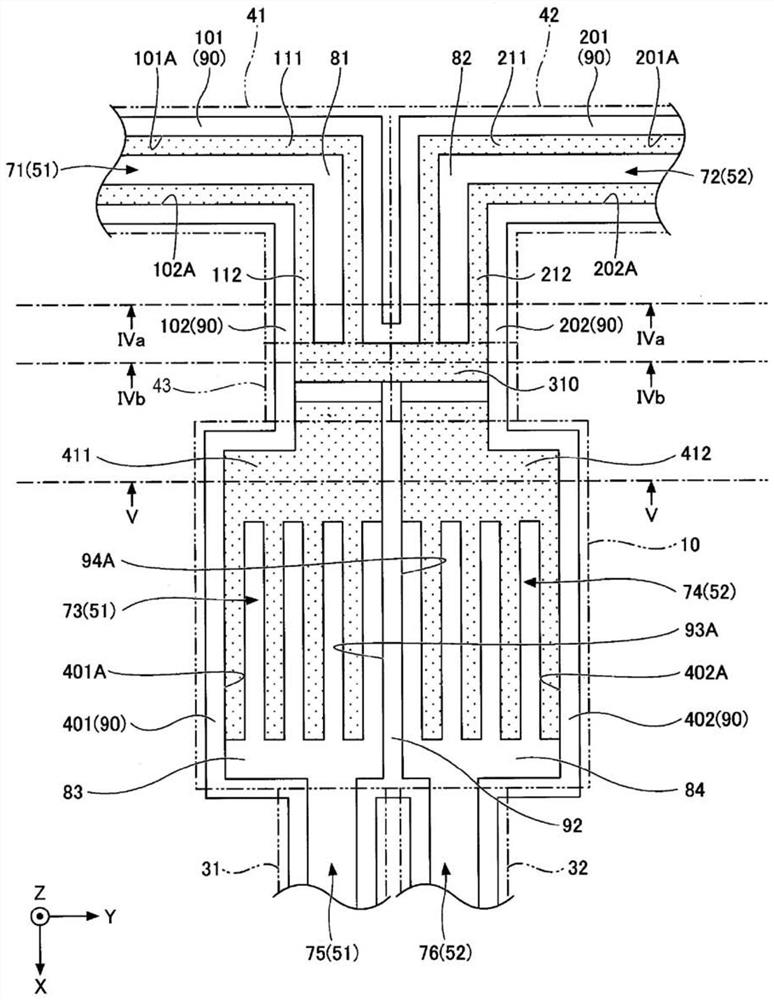

[0064] In the second embodiment, the configuration of the evaporator 10 is different from that of the first embodiment. In the second embodiment, descriptions of the same constituent parts as those of the above-described embodiments may be omitted. Figure 6 is a schematic plan view depicting the evaporator 10 , the first liquid pipe 41 , the second liquid pipe 42 , the connecting portion 43 , the first vapor pipe 31 , and the second vapor pipe 32 of the loop heat pipe according to the second embodiment. exist Figure 6 , not shown as the outermost metal layer on one side ( Figure 4A , Figure 4B and Figure 5 Metal layer 61) shown in .

[0065] In the second embodiment, the second condenser 22 is arranged in an environment that is easier to dissipate heat than the first condenser 21 . For example, the second condenser 22 is arranged in a larger area than the first condenser 21 , or a cooling fan is arranged in the vicinity of the second condenser 22 . The cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com