Protective packaging device for preventing liquid level meter from being broken

An anti-breakage and liquid level gauge technology, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaged items, etc., can solve problems such as lack of enhanced protection, poor support effect, and vibration of liquid level gauges, so as to reduce the probability of breakage , Long protection time, strengthen the effect of fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

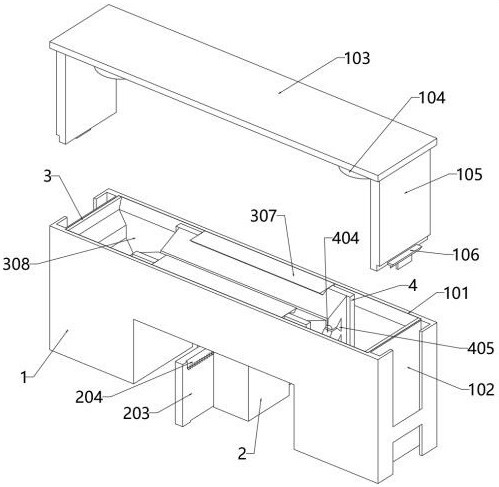

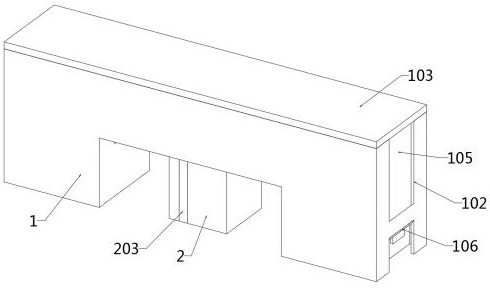

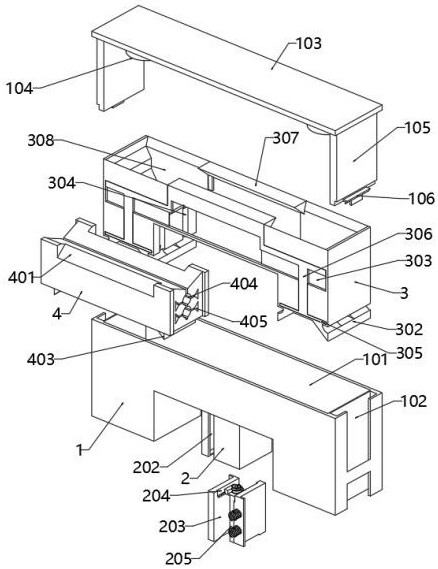

[0033] Example: Please refer to Figure 1 to Figure 9 :

[0034]The present invention proposes a protective packaging device for liquid level meter anti-shattering, including: main body 1; the main body 1 is an inverted U-shaped structure, and the main body 1 is made of metal iron, so that the main body 1 can be harder and can withstand external impact Afterwards, it will not be directly damaged. An inner part 3 is provided on both sides of the interior of the main body 1. The inner part 3 is a rectangular structure. The interior of the inner part 3 is provided with a rectangular inner cavity 308 for embedding the valve of the liquid level gauge. The valve can be in contact with the inner part 3 at the first time. The inner part 3 is made of rubber, which can effectively buffer the impact force when it is in contact with the valve. There is an inclined block on the outside of the rectangular inner cavity 308, which is used to guide the valve to be embedded. , there are two in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com