Tool steel capable of adapting to large-deformation cold machining forming, preparation method of tool steel, sleeve and preparation method of sleeve

A large deformation, tool steel technology, applied in the field of tool steel processing, can solve the problems of high torque, high wear resistance, high life performance, cold heading and cold stamping performance, etc., to achieve low comprehensive processing cost, Effect of low spheroidizing annealing temperature and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

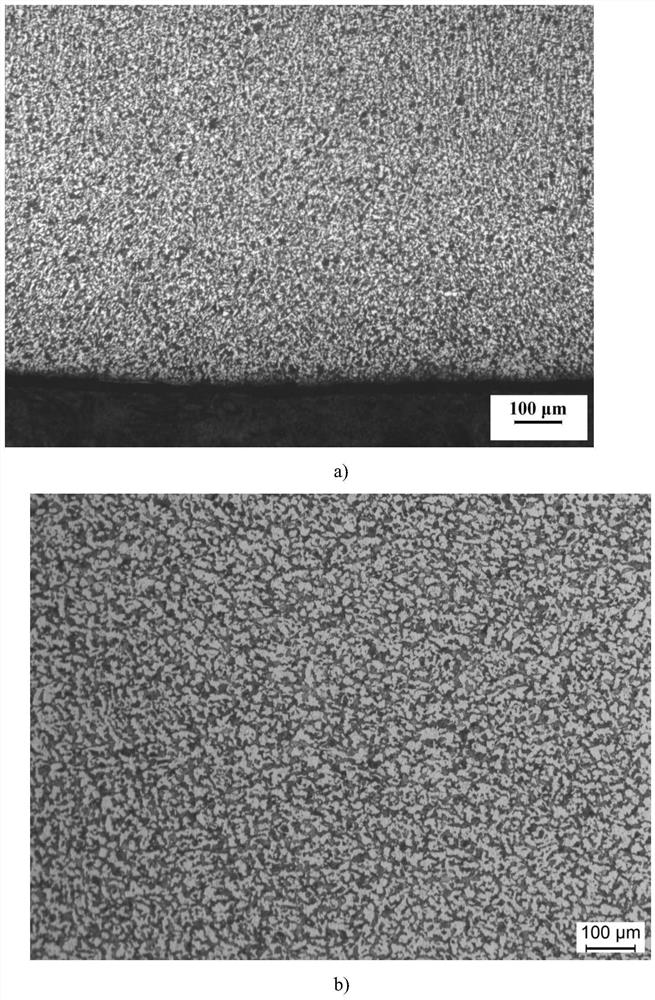

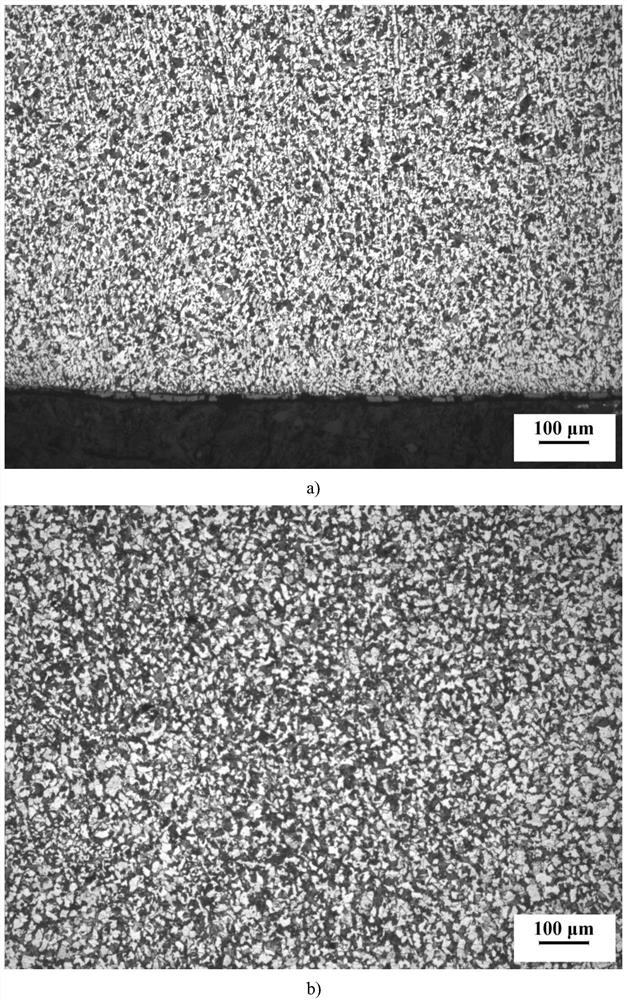

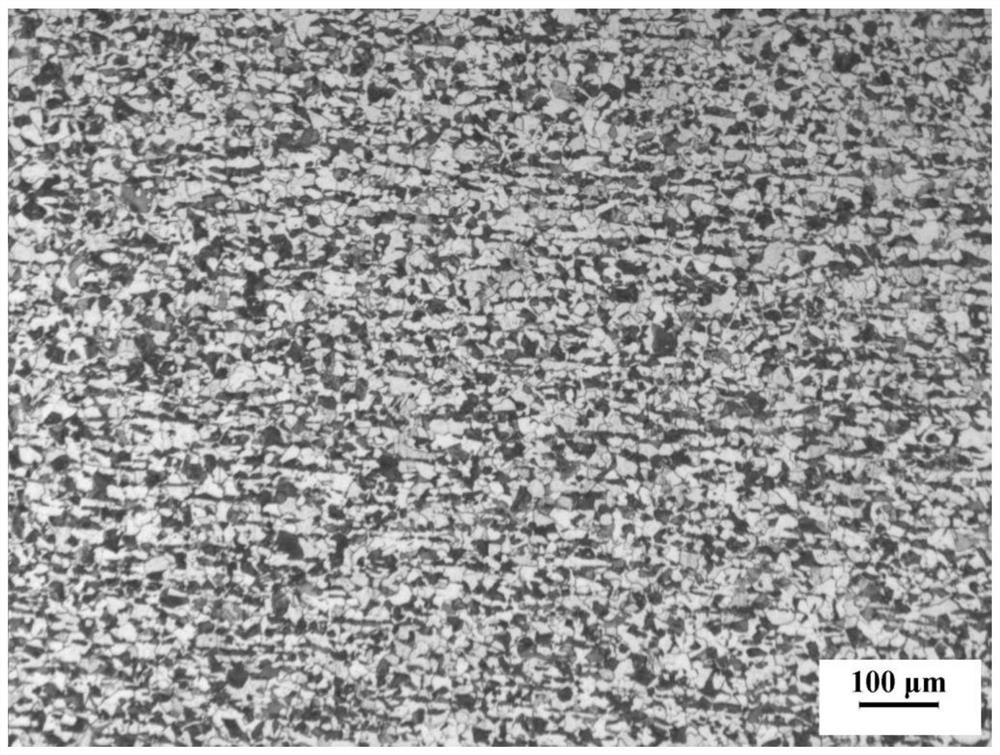

Image

Examples

preparation example Construction

[0059]The second aspect of the present invention provides the preparation method of the tool steel mentioned in the first aspect, the method includes: proportioning raw materials according to the required components, and sequentially smelting the raw materials, controlled rolling and controlled cold rolling, and cooling.

[0060] In the present invention, it can be understood that the "proportioning raw materials according to the required components" refers to the proportioning of raw materials according to the composition of the desired product tool steel. In the present invention, the raw materials are basically completely converted into the elemental components of the product tool steel, and a small amount of element loss can be supplemented by subsequent replenishment as needed, that is, the amount of each element of the raw material is the same as that of the product tool steel.

[0061] According to the present invention, preferably, the smelting includes converter smelti...

Embodiment 1

[0110] Preparation of tool steel:

[0111] According to the composition and ratio of raw materials shown in Table 1, smelting is carried out first. The specific smelting process is followed by converter smelting, LF furnace refining, RH furnace vacuum treatment and billet protection continuous casting. The corresponding process conditions are shown in Table 2. Among them The vacuum treatment process of the RH furnace is as follows: after cyclic treatment at a vacuum degree ≤ 0.267kPa for 5 minutes, ferro-titanium is added as needed (the amount of ferro-titanium is such that the total amount of each element meets the content of the corresponding elements in Table 1), and boron is added as needed after repressing Iron (the amount of ferroboron makes the total amount of each element meet the content of the corresponding elements in Table 1). The billet protection continuous casting process is as follows: using argon blowing protection and integral nozzle casting to avoid contact ...

Embodiment 2-10

[0115] Carry out according to the method of embodiment 1, difference is to carry out according to the process parameter shown in table 1-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com