Medium-size back plate punching distortion resisting galvanized steel and manufacturing method thereof

A technology of anti-stamping and galvanized steel, which is applied in the field of improving the distortion of the steel plate stamping process. It can solve the problems of distortion and material yield strength that cannot meet the requirements of improving the stamping distortion. The uniformity of the material’s transverse properties, etc., achieves a large process window and industrial realization Easy, productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

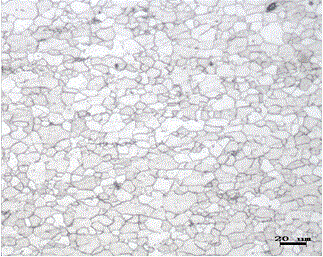

[0032]Example 1 and Comparative Example 3 respectively compared the effects of adding boron and low manganese content on the yield strength of the finished product. Through comparison, it was found that the yield strength of adding 0.0020% boron was 216MPa, and no distortion occurred after stamping, while the yield strength of no boron was added It is 260MPa, twisted after stamping, and the addition of boron element in the element is beneficial to reduce the yield strength of the steel plate. image 3 The uniformity distribution diagram of the plate width longitudinal yield strength of Example 1 is shown.

Embodiment 2

[0033] The comparison between Example 2 and Comparative Example 1 shows that the addition of boron element affects the uniformity of material performance. Through comparison, it is found that the addition of 0.0015% boron element Example 1 has a yield range of 5MPa, and no distortion occurs after stamping, while the comparative example without adding boron element 1 The yield difference is 15MPa, and as a result, distortion occurs after stamping. Figure 4 The distribution diagram of the uniformity distribution of the plate width longitudinal yield strength of Comparative Example 1 is shown.

[0034] Example 4 and Comparative Example 2 respectively compared the influence of different carbon contents on the yield strength of the finished product. By comparison, it was found that the yield strength of the added 0.014% carbon element was 200MPa, and no distortion occurred after stamping, while the yield strength of the added 0.04% carbon element was 265MPa. Distortion occurs afte...

Embodiment 7

[0036] Example 7 and Comparative Example 5 compared the influence of the change of coiling temperature on the uniformity of material properties. Through comparison, it was found that the yield strength of Example 7 was 205 MPa when the coiling temperature was 746 °C, and no distortion occurred after stamping, while the coiling temperature was 600 °C. In Example 5, the yield strength was 245 MPa, and as a result, distortion occurred after stamping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com