Silver tungsten carbide graphite composite material added with nickel alloy and preparation method thereof

A tungsten carbide graphite and composite material technology, which is applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of easy segregation of material components, high environmental hazards, high cost of ammonia nitrogen waste liquid treatment, and improve the compactness. , The effect of good tissue uniformity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

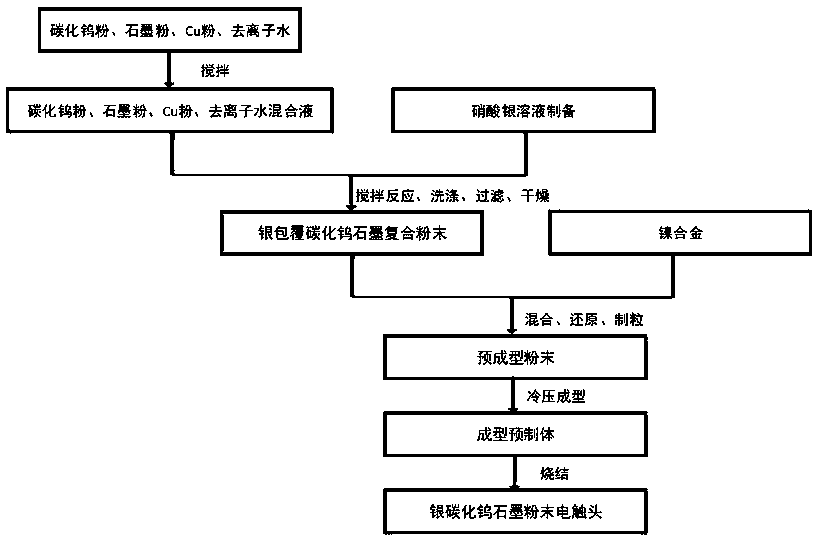

[0041] The embodiment of the present invention also provides a preparation method of silver tungsten carbide graphite composite material with nickel alloy added, the process flow chart is as follows figure 1 shown, including the following steps:

[0042] (1) Preparation of composite powder of silver-coated tungsten carbide and silver-coated graphite;

[0043] (2) Add nickel alloy powder to the composite powder, and obtain preformed powder through mechanical powder mixing, reduction and granulation;

[0044] (3) Initially press the preformed powder into a preform;

[0045] (4) Sintering the preform to obtain a silver-tungsten carbide-graphite composite material with nickel alloy added.

[0046] Preferably, the composite powder in step (1) is prepared by chemical coating method, including the following steps:

[0047] (11) Preparation of silver salt solution;

[0048] (12) Prepare a mixed solution containing tungsten carbide powder, graphite powder, reducing powder and water...

Embodiment 1

[0061] Embodiment 1 of the present invention provides a silver tungsten carbide graphite composite material with nickel alloy added and a preparation method thereof, comprising the following steps:

[0062] (1) Preparation of silver tungsten carbide graphite composite powder by chemical coating method:

[0063] Calculate the mass of tungsten carbide powder, graphite powder, copper powder and silver nitrate according to the composition of silver-coated tungsten carbide graphite composite powder: silver 85%, tungsten carbide 12%, graphite 3%;

[0064] Prepare a silver nitrate solution a with a concentration of 5 mol / L and a temperature of 25°C;

[0065] Select tungsten carbide powder with an average particle size of 2 μm, graphite powder of 4 μm, copper powder of 300 mesh and deionized water to prepare mixed solution b. Calculated by the complete reaction of copper powder in mixed solution b to generate 1 kg of silver, the required amount of deionized water is 4 L. The temperat...

Embodiment 2

[0075] Embodiment 2 of the present invention provides a silver tungsten carbide graphite composite material with nickel alloy added and a preparation method thereof, comprising the following steps:

[0076] (1) Preparation of silver tungsten carbide graphite composite powder by chemical coating method:

[0077] Calculate the mass of tungsten carbide powder, graphite powder, copper powder and silver nitrate according to the composition of silver-coated tungsten carbide graphite composite powder: silver 85%, tungsten carbide 12%, graphite 3%;

[0078] Prepare a silver nitrate solution a with a concentration of 7mol / L and a temperature of 25°C;

[0079] Select tungsten carbide powder with an average particle size of 2 μm, graphite powder with 28 μm, copper powder with 200 mesh and deionized water to prepare mixed liquid b. Calculated by the complete reaction of copper powder in mixed liquid b to generate 1 kg of silver, the required amount of deionized water is 5 L. The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com