Deformed annual plank

A technology for wood planks and annual grains, applied in the field of deformed annual grain wood planks and their production, can solve the problems of low price, difficulty in collecting and inheriting high-quality products, and limited plate size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

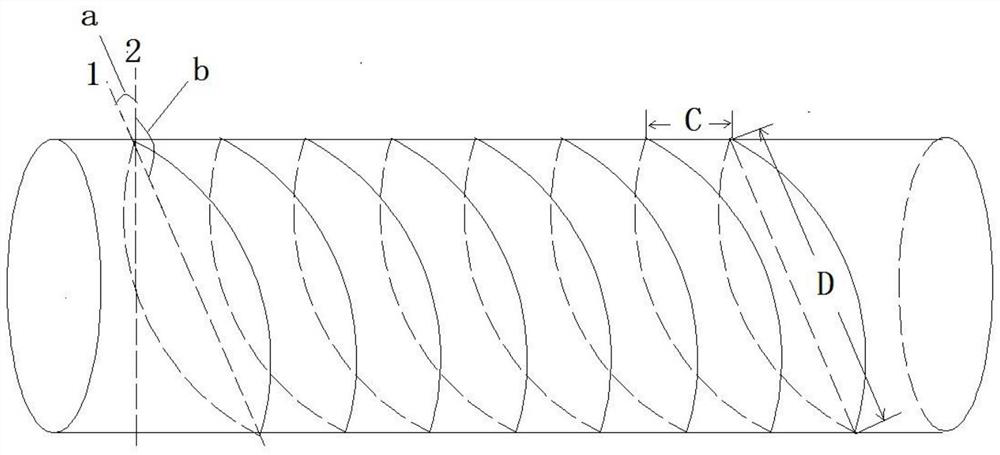

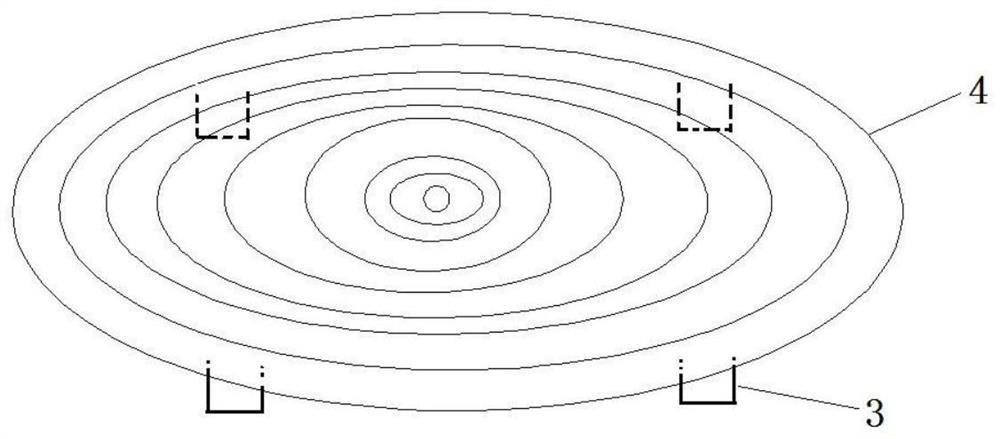

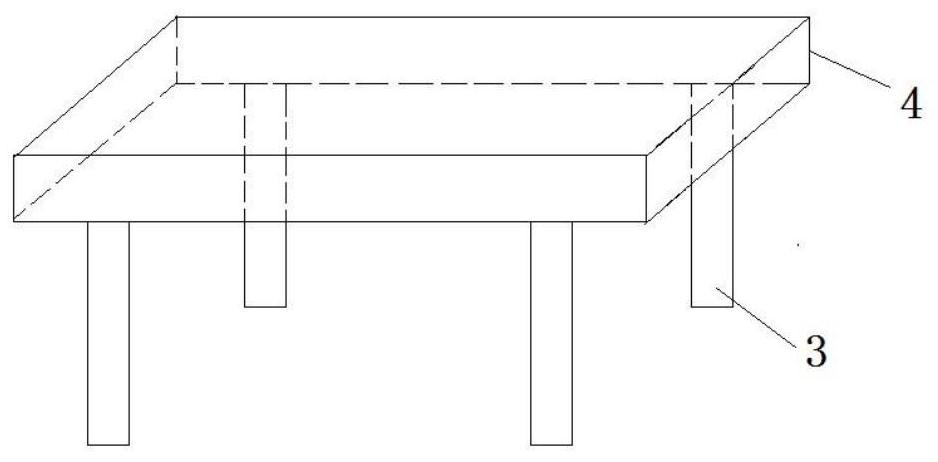

[0021] Such as Figure 1 to Figure 3 As shown, the manufacturing method of the deformed annual pattern plank of the present invention is to use a blade saw, band saw, gang saw, chain saw or circular saw to cut the log with a large diameter (120-200 cm) at equal intervals or at different intervals along its length direction. Cut into required wood sections at intervals, and the cutting surface forms an angle of 10-80 degrees or 100-170 degrees with the cross-section of the log; the wood sections are polished and planed to become planks, and the end faces of the planks have deformed year patterns. Generally, the spacing of equidistant cutting is 38 centimeters, and the end face of the obtained plank is more than 2.5 meters long.

[0022] The traditional cutting method makes the log into planks. Usually, only the width of the plank in the middle of the trunk is the same as the diameter of the log, and the width of the planks on both sides gradually becomes smaller. Small planks a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com