Zero setting method for grinding head and workpiece and grinding equipment

A technology of workpieces and grinding heads, which is applied in the field of parts processing, can solve the problems of long time-consuming, time-consuming alignment, and inability to meet the requirements of grinding accuracy, and achieve the effects of compensating loss, saving alignment time, and improving alignment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

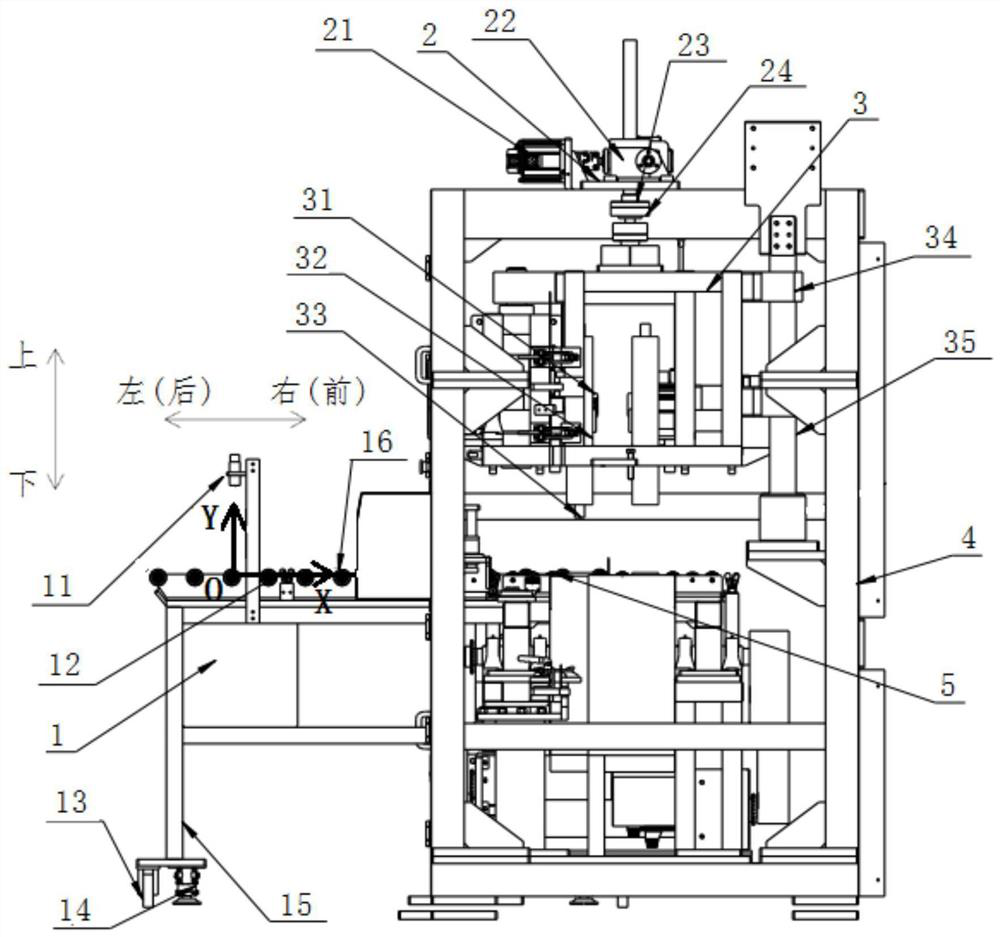

[0078] combine figure 1 As shown, the present embodiment provides a kind of grinding equipment, comprising:

[0079] For implementing the method for aligning the grinding head and the workpiece as described above, the grinding equipment includes: an extension conveying table 1, and the extension conveying table 1 includes: a conveying unit 16, which is suitable for supporting and conveying the workpiece; a thickness measuring sensor 11 , arranged directly above the conveying unit 16 , suitable for measuring the thickness value D of the workpiece.

[0080] Preferably, the conveying unit 16 includes rollers or belts.

[0081] Preferably, the conveying unit 16 drives the workpiece to move on the extension conveying table 1 , and when the workpiece touches the travel switch 12 , the thickness measuring sensor 11 is activated.

[0082] Specifically, the epitaxial conveying table 1 further includes: a travel switch 12 , which is arranged in front of the thickness measuring sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com