Test fixture, test device and test method of electrode patch

A technology of electrode patch and test fixture, which is applied in the direction of measuring device, electrical connection test, measuring device shell, etc., can solve the problem of inability to directly and conveniently detect thermal components and flexible circuit board welding qualified thermal components and electrodes, etc. Achieve the effect of avoiding inaccurate testing, clear interface and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

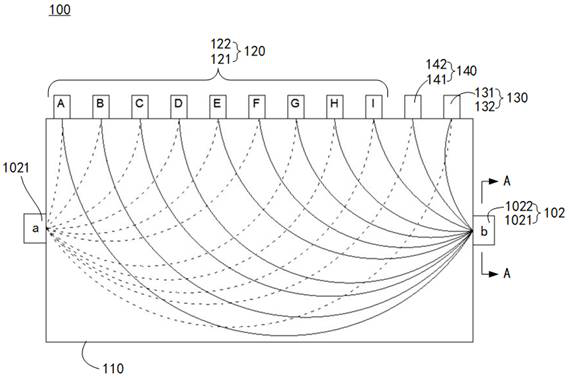

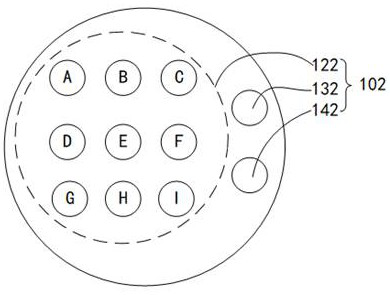

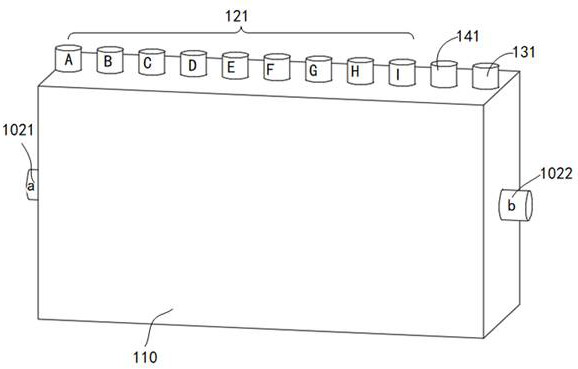

[0084] In the first embodiment, the component adapter assembly 120 includes: a component interface 121 and a component pin 122 electrically connected to each other, the component interface 121 is used to electrically connect with the component tester, and the component pin 122 is used to connect with the electrode patch The thermosensitive element 201 is electrically connected.

[0085] In the second embodiment, the electrode adapter assembly 130 includes: an electrode interface 131 and an electrode pin 132 that are electrically connected to each other. The electrodes 202 are electrically connected.

[0086] In the third embodiment, the ground transition assembly 140 includes: a ground wire interface 141 and a ground wire pin 142 electrically connected to each other, the ground wire interface 141 is used for electrical connection with the component tester, and the ground wire pin 142 is used for Electrically connected to ground.

[0087] It should be noted that, the above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com