Method for machining multiple rows of inclined grooves in shaft parts

A technology of shaft parts and processing methods, which is applied in the field of chute processing, can solve the problems of difficult and precise processing of multi-row chute, and achieve the effect of overall simplicity and reliability, easy popularization and application, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

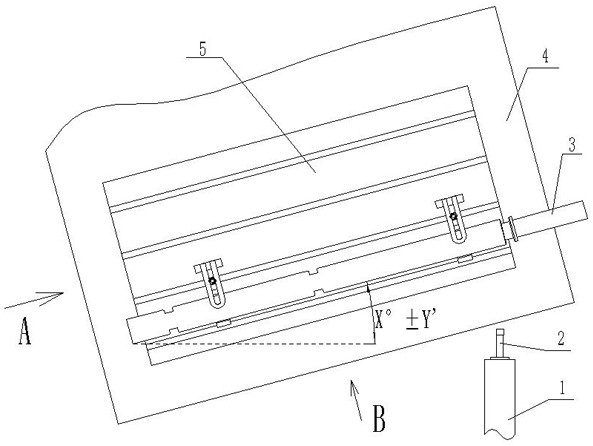

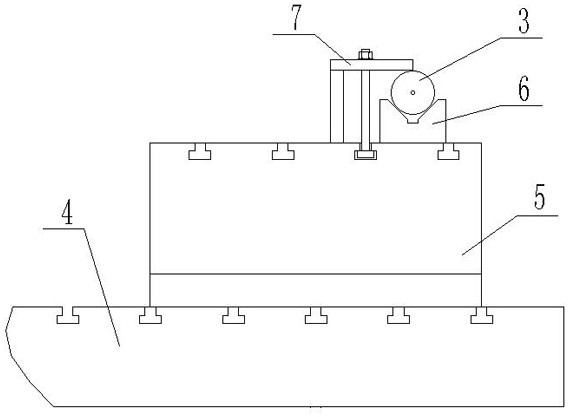

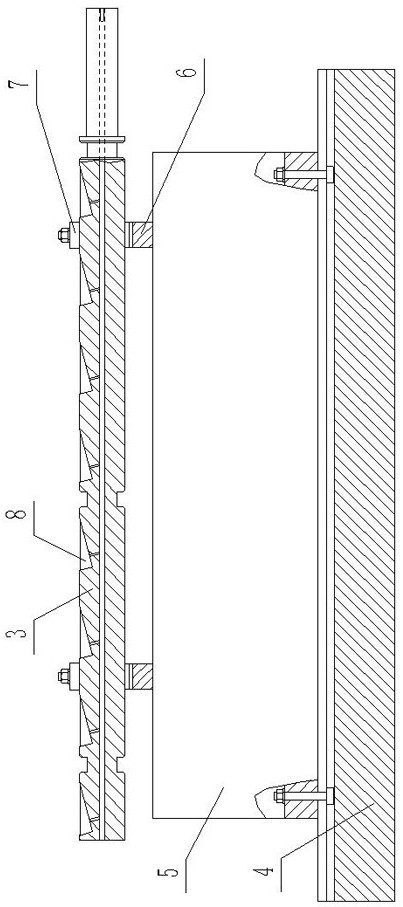

[0031] Referring to the accompanying drawings, the specific implementation is as follows:

[0032] A method for processing multiple rows of chute grooves on a shaft part, which is used to process multiple rows of chute grooves 8 on the outer circumference of a shaft part 3, and the multi-row chute grooves 8 are uniform along the circumferential direction of the shaft part 3 The chute 8 in the same row is evenly spaced along the axial direction of the shaft part 3. The chute 8 is formed by the cooperation of two sections of side walls 9 and two sections of bottom surfaces. The side walls 9 of the chute 8 are aligned with the shaft The axes of the chute parts 3 are parallel, and the two sections of side walls 9 of the chute 8 are symmetrical about a plane containing the axis of the shaft parts 3, which is the datum plane of the chute 8, and the bottom surface of the chute 8 is perpendicular to the datum plane, and The bottom surfaces of the two sections of the chute 8 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com