Method for finely machining pyramid cover of drum part of metallurgical machine

A component and reel technology, which is applied in the processing field of metallurgical machinery reel parts, can solve problems such as difficult dimensional accuracy, quadrangular pyramid sleeve or the influence of reel accuracy and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

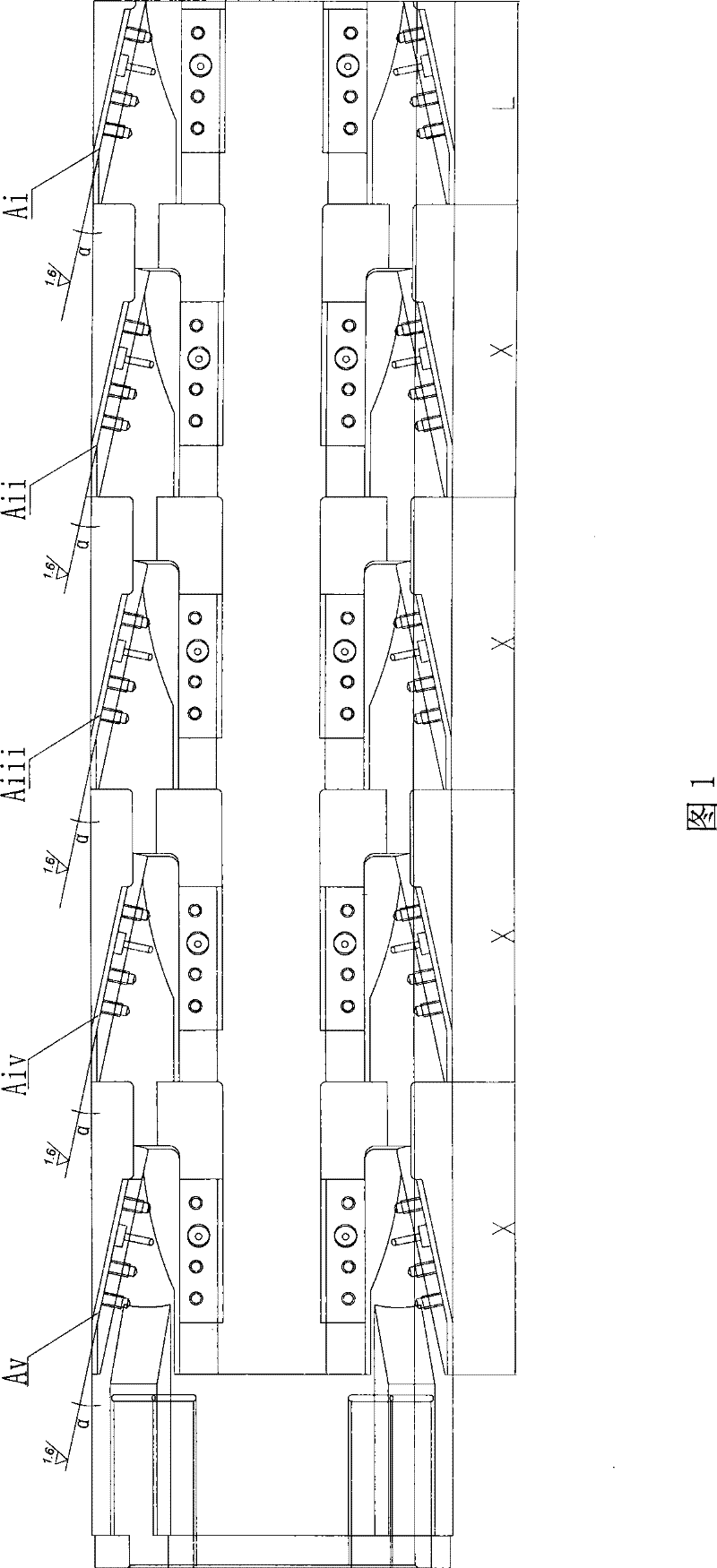

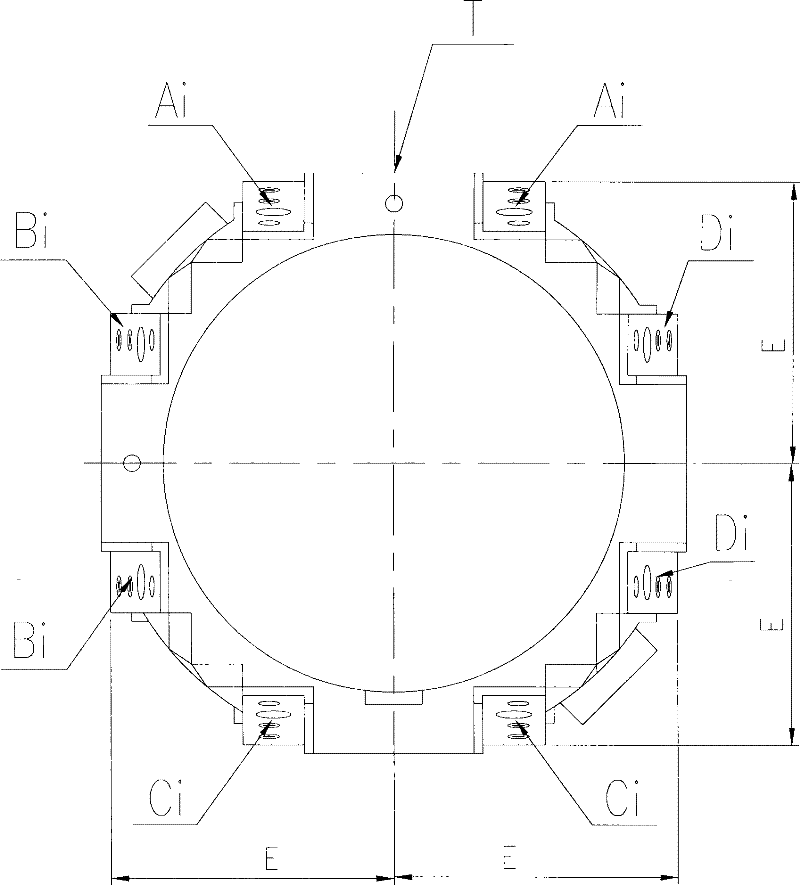

[0053] The finishing method of the pyramid sleeve of the metallurgical machinery reel part of the present invention uses an indexing device to index the pyramids distributed on the circumference of the pyramid sleeve.

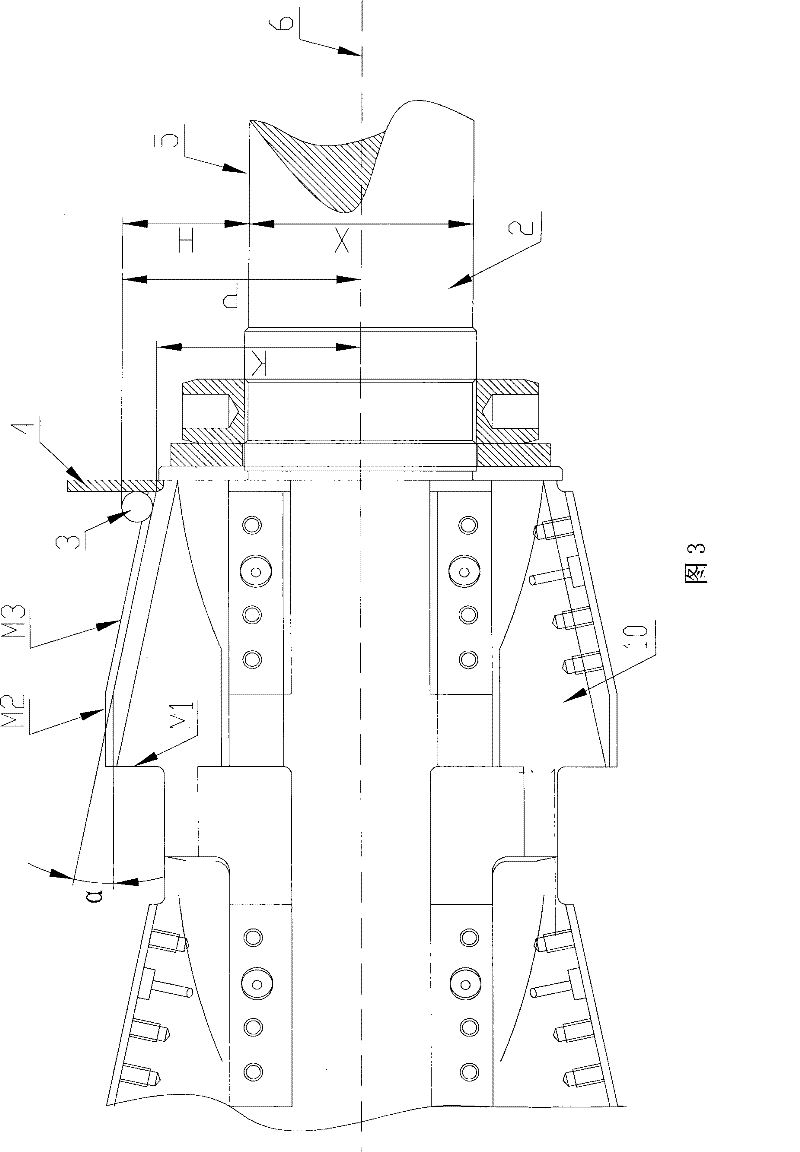

[0054] The indexing device that the present invention adopts is as Figure 4 As shown, it includes a frame 31, a mandrel 32, a bearing seat 33, a fixing flange 34, a workpiece fixing device 35, an adjusting device 36, and a positioning device 37;

[0055] The two ends of the frame 31 are respectively provided with a bearing seat 33, and the upper part of the bearing seat 33 is provided with a matching bearing cover 38, and the bearing seat 33 and the bearing cover 38 jointly fix the mandrel 32 on the frame 31; the mandrel 32 is located at One end of the inner part of the two bearing seats 33 is fixedly provided with a fixed flange 34 , and the other end is provided with a workpiece fixing device 35 . An adjusting device 36 is also provided at one end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com