Multi-position cleaning equipment and method for porous glass plate gas absorption bottle

A gas absorption, porous glass plate technology, applied in cleaning methods and utensils, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of long time, occupied personnel, and small cleaning quantity, and achieves expansion of cleaning quantity and cleaning effect. Good and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

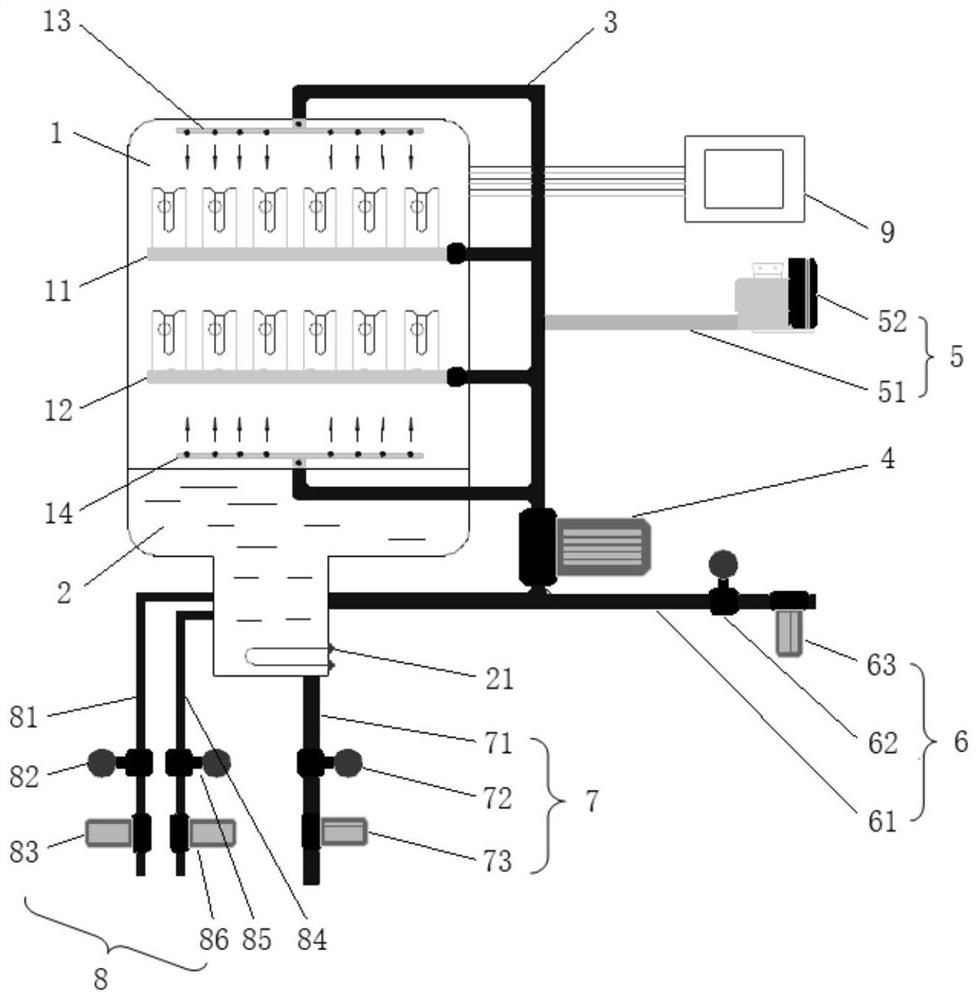

[0055] This embodiment provides a multi-position cleaning device for a porous glass plate gas absorption bottle, such as figure 1 shown, including:

[0056] The casing, the upper part of the casing is used as the upper working chamber 1, and the lower part of the casing is used as the lower liquid storage chamber 2, and the lower liquid storage chamber 2 is used to store the working medium, and the working medium includes pure water, ultrapure water or additive Pure water or ultrapure water of the cleaning solution, the cleaning solution includes acid solution or alkali solution, and the cleaning solution is added to make the cleaning more effective and thorough; Form or Step Variation.

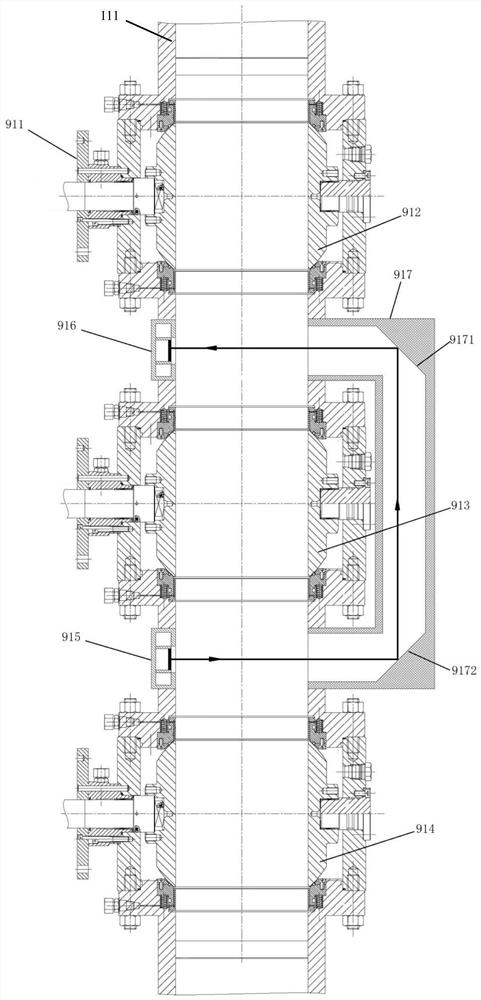

[0057] There are at least two layers of cleaning racks arranged up and down. The cleaning rack is placed in the upper working chamber 1. The cleaning rack is a hollow pipe structure with multiple basket racks. The basket rack has two support arms. One end of the glass plate gas absorption b...

Embodiment 2

[0068] This embodiment provides a multi-position cleaning device for porous glass plate gas absorption bottles, which is different from Embodiment 1 in that the arrangement of the baskets is different, specifically: two supports for each basket on a cleaning rack One end of the arm is coaxial, and the axes of the one end of the two support arms of all the multi-position baskets on it are parallel to each other.

Embodiment 3

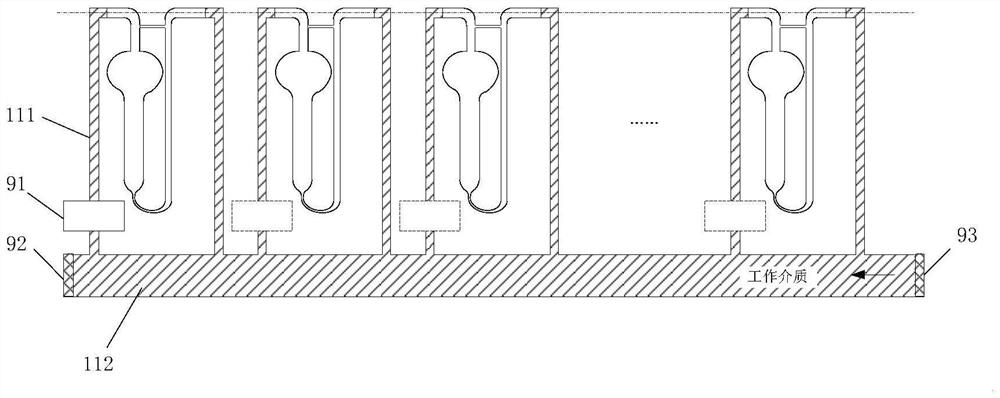

[0070] This embodiment provides a multi-position cleaning device for a porous glass plate gas absorption bottle, such as figure 2 As shown, the difference from Embodiment 1 is that the multi-position cleaning equipment also includes:

[0071] The output switch valve 92 and the input switch valve 93, the input switch valve 93 is installed at the input end of the rack seat 112 of the cleaning rack, and the output switch valve 92 is installed at the output end of the rack seat 112 of the cleaning rack for synchronous opening and closing operation In order to open or block the circulation of the working medium in the cleaning rack, when the cleanliness test is required, the output switch valve 92 and the input switch valve 93 can be closed at the same time, so that the working medium can stand for a period of time in the cleaning rack to eliminate Air bubbles in the working medium to improve the accuracy of cleanliness detection; and

[0072] The cleanliness detection device 91 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com