Sliding block and plastic pulling part deformation adjustable separating and inverted buckling mechanism for injection mold

A technology of injection mold and deformation mechanism, which is applied in the field of deformation and undercut mechanism of plastic part with adjustable slider of injection mold. The effect of reducing mold manufacturing costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

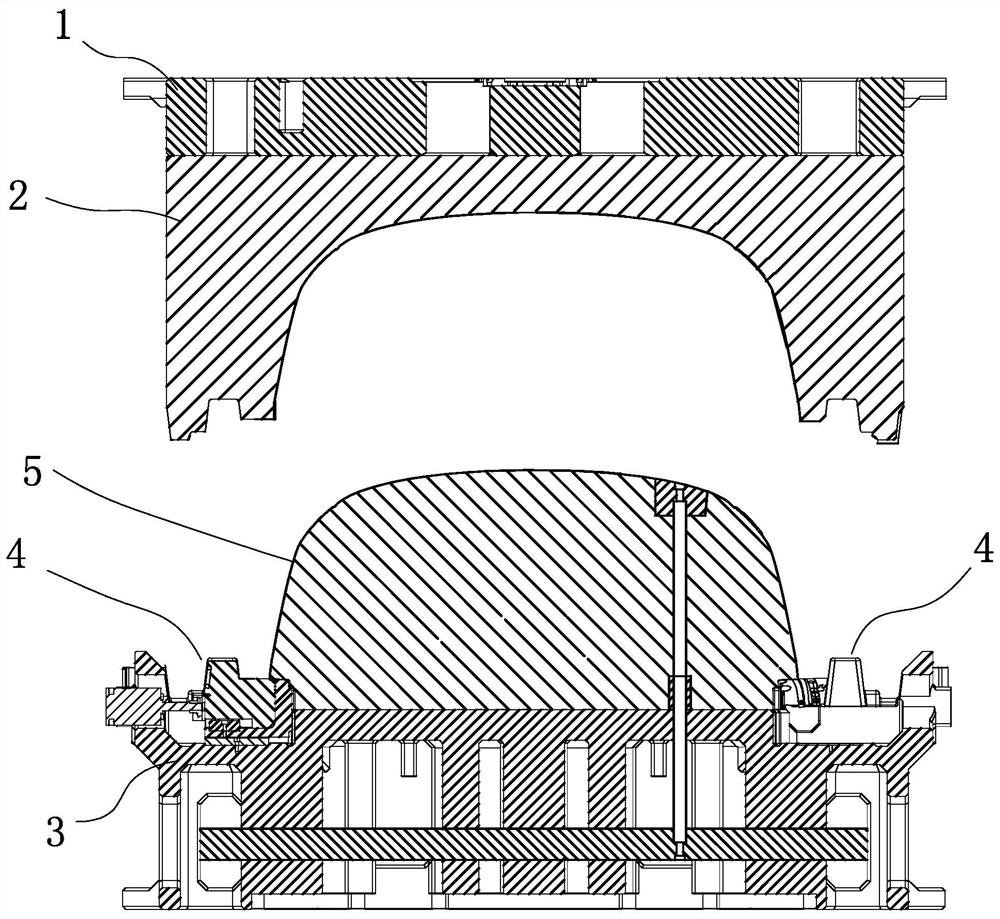

[0032] Such as figure 1 In the shown embodiment 1, an injection mold can adjust the sliding block deformation and undercut mechanism of the stretched plastic part, including the upper doubler plate 1 and the lower doubler plate, wherein the upper doubler plate 1 includes a hot runner plate, and the upper doubler plate 1 There is a cavity 2 connected to the bottom of the doubler plate, the lower doubler plate includes mold feet, a core 3 is connected to the lower doubler plate, an ejector plate is arranged between the core 3 and the lower doubler plate, and a straight ejector rod is arranged on the ejector plate. The straight ejector pin passes through the core 3 .

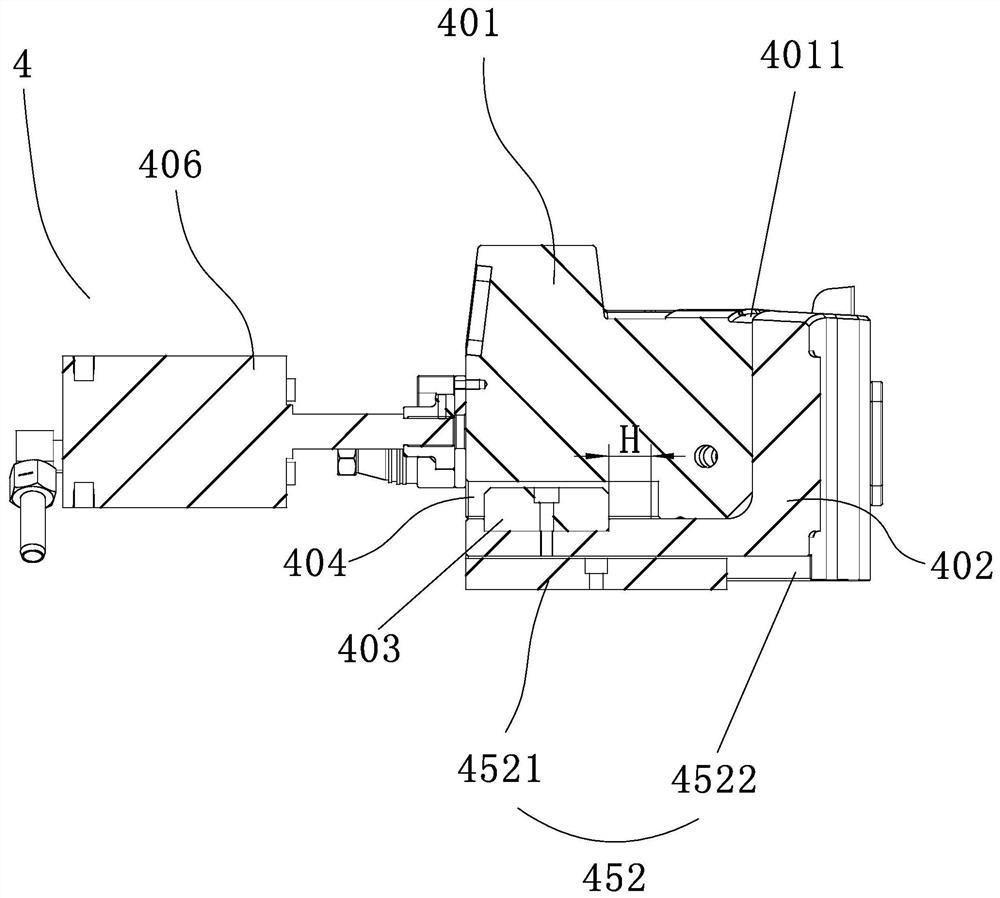

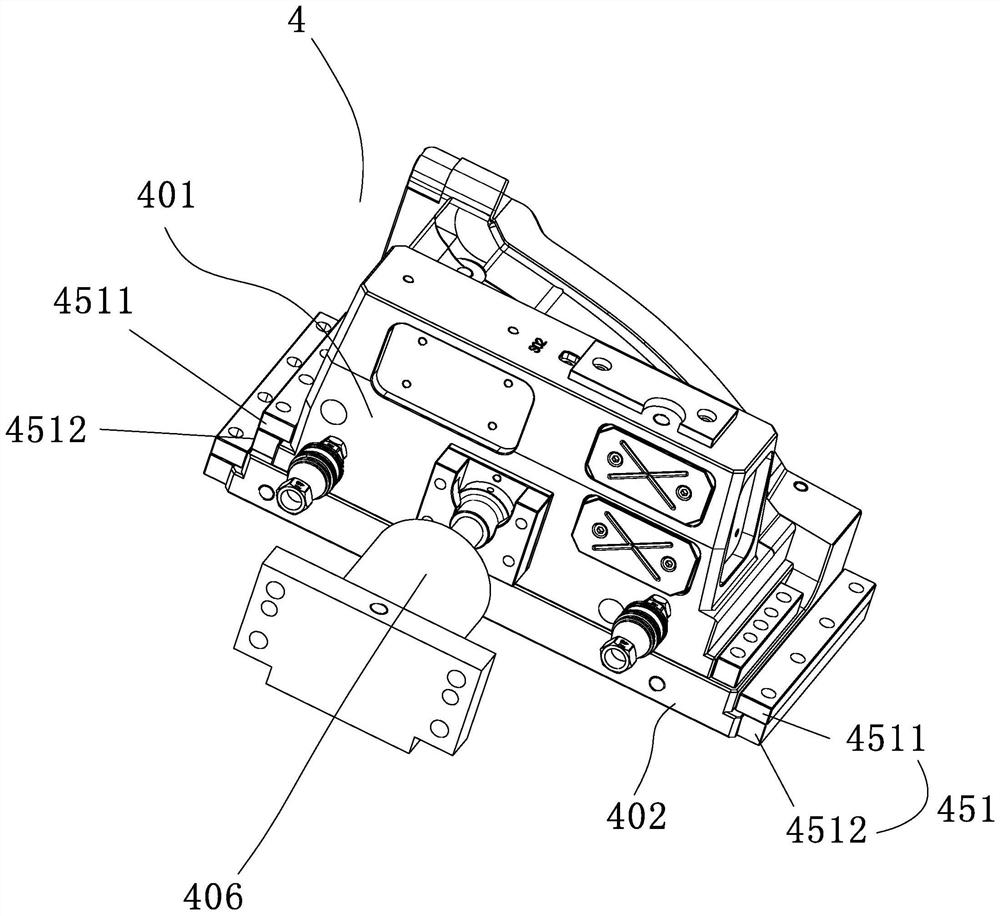

[0033] Such as figure 2 , image 3 As shown, the plastic part deformation mechanism 4 is provided on the core 3, and the plastic part deformation mechanism 4 includes a deformation slider 402 and a driving slider 401, and the driving slider 401 is slidably arranged on the deformation slider 402. The deformation...

Embodiment 2

[0041] The technical solution of embodiment 2 is basically the same as the technical solution of embodiment 1, the difference is that: the limit block 403 is arranged on the driving slider 401, and the limit chute 404 is arranged on the pulling deformation slider 402, in Before the injection molded product 5 is pulled and deformed, a distance is provided between the limit block 403 and the end surface of the limit chute 404 away from the injection molded product 5 .

Embodiment 3

[0043] The technical solution of embodiment 3 is basically the same as the technical solution of embodiment 1, the difference is that: the limiting chute 404 is arranged on the driving slider 401, and the limiting chute 404 extends to a side where the driving slider 401 is away from the product. On the side and communicated with the outside world, such a setting is convenient to cooperate with the first guide structure 451, and slide the driving slider 401 onto the pulling deformation slider 402, which is convenient and quick to install.

[0044] Or the limit chute 404 is arranged on the drawing deformation slider 402, at this time the limit chute 404 extends to the side surface of the drawing deformation slider 402 close to the injection molded product 5 and communicates with the outside world, such setting is also convenient for driving the slider 401 quick installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com