Sealing performance detection device

A technology for airtightness detection and detection of containers, which is applied in the field of airtightness detection devices, can solve problems such as insufficient locking force, decline in container airtightness, and aging relaxation, so as to reduce the probability of misjudgment, stabilize the airtightness, and solve the problems of human eyes and manpower. The effect of the dependency problem on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

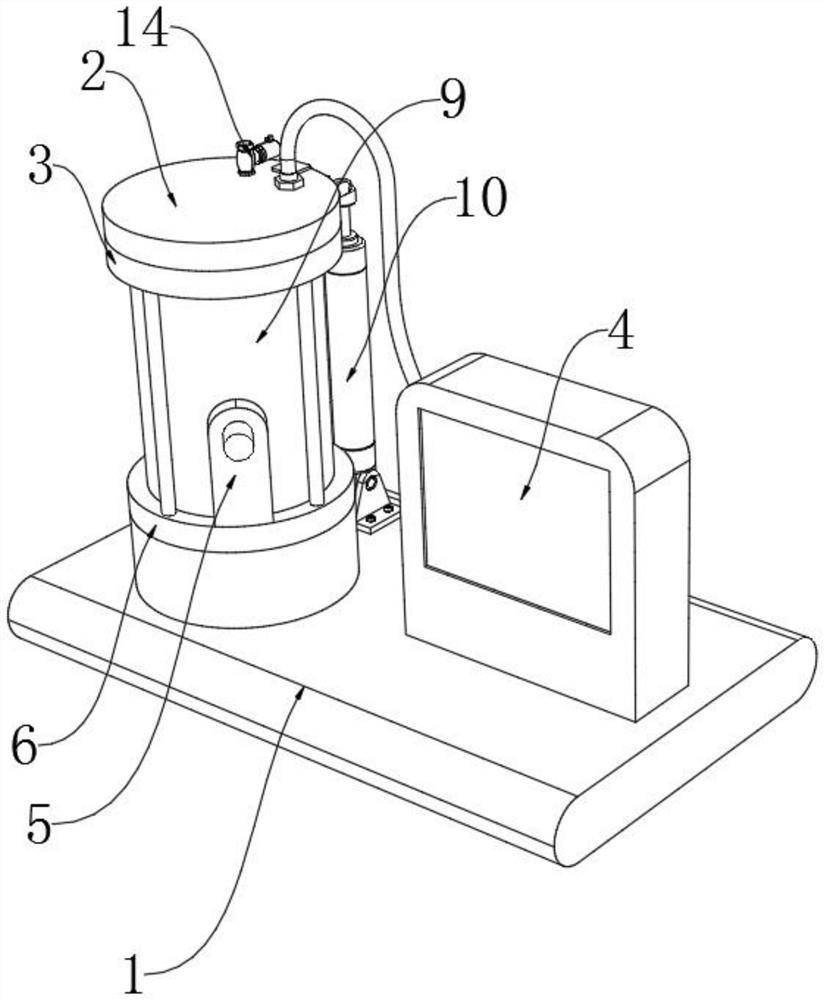

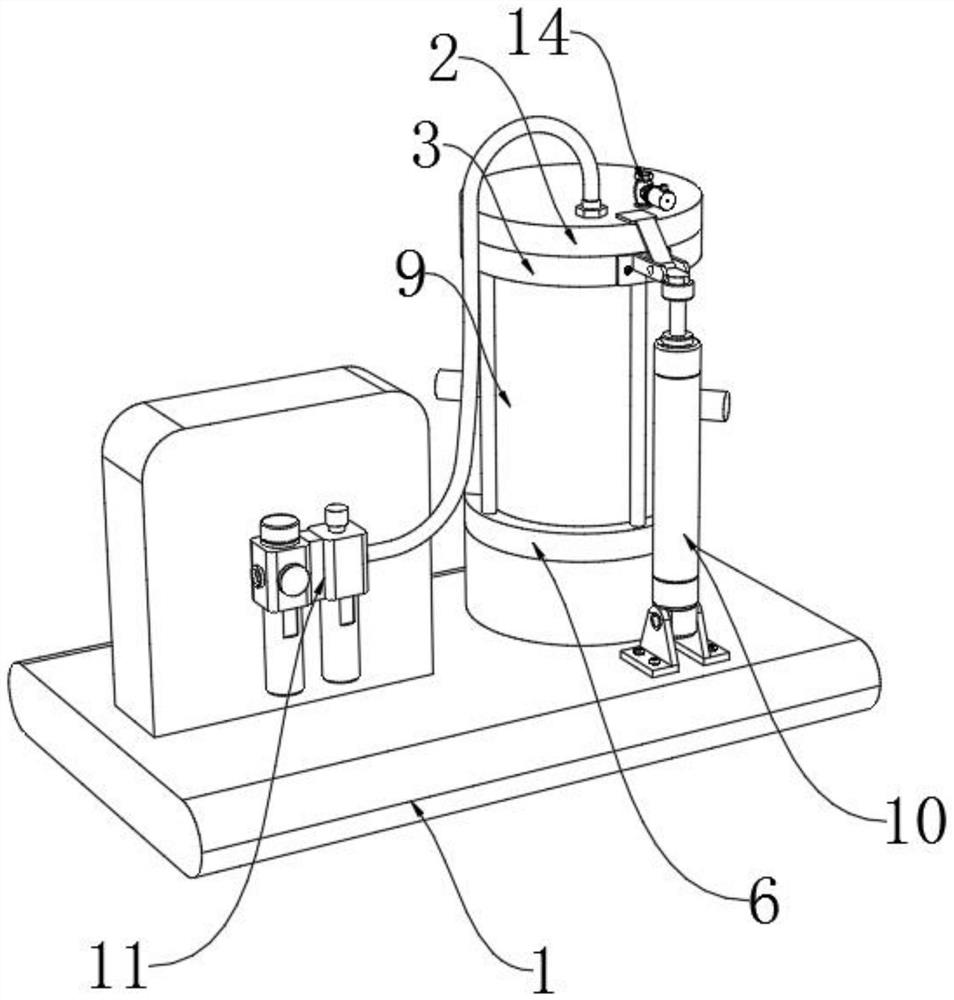

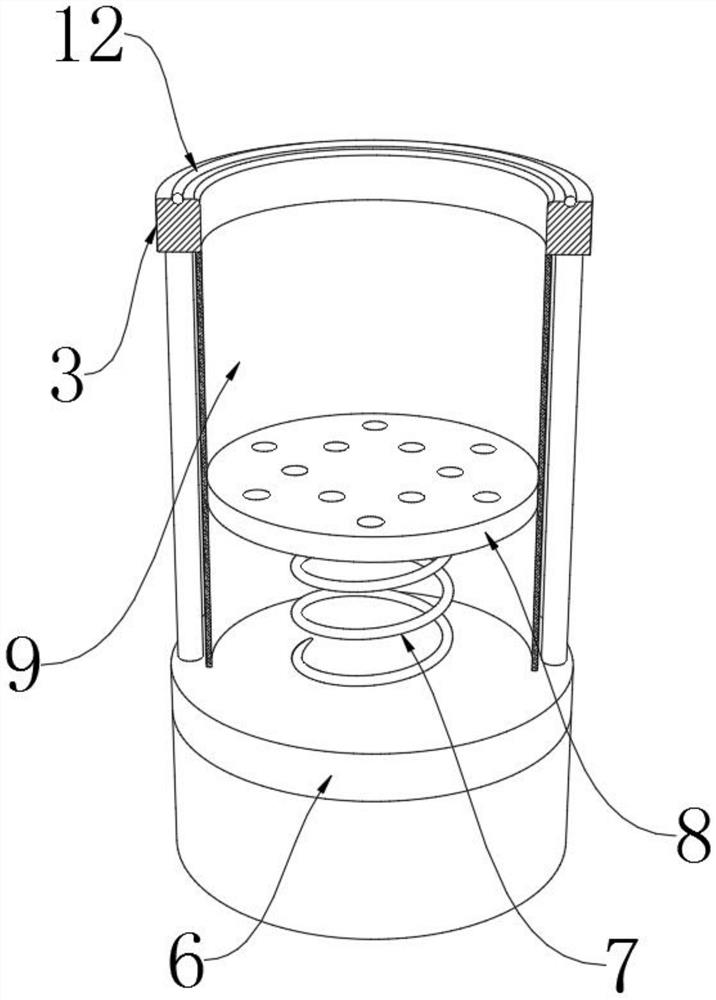

[0030] see Figure 1-Figure 6 , a kind of airtightness detection device, comprises console 1, and the upper end of console 1 is provided with detection container, specifically, detection container comprises upper cover 2, flange frame 3, lower cover 6 and transparent acrylic cylinder 9, upper cover 2 and the inside of the lower cover 6 are provided with electromagnets; the lower end of the lower cover 6 is fixed with the console 1, the flange frame 3 is fixed at the upper end of the lower cover 6, and a transparent The upper end of the acrylic cylinder 9 and the flange frame 3 is provided with an upper cover 2. In order to ensure the tightness between the upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com