Needle-holding unit for circular knitting machine

A knitting machine, circular technology, applied in the field of needle holding unit, needle holding cylinder or needle holding plate, which can solve problems such as butt breakage and yarn breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

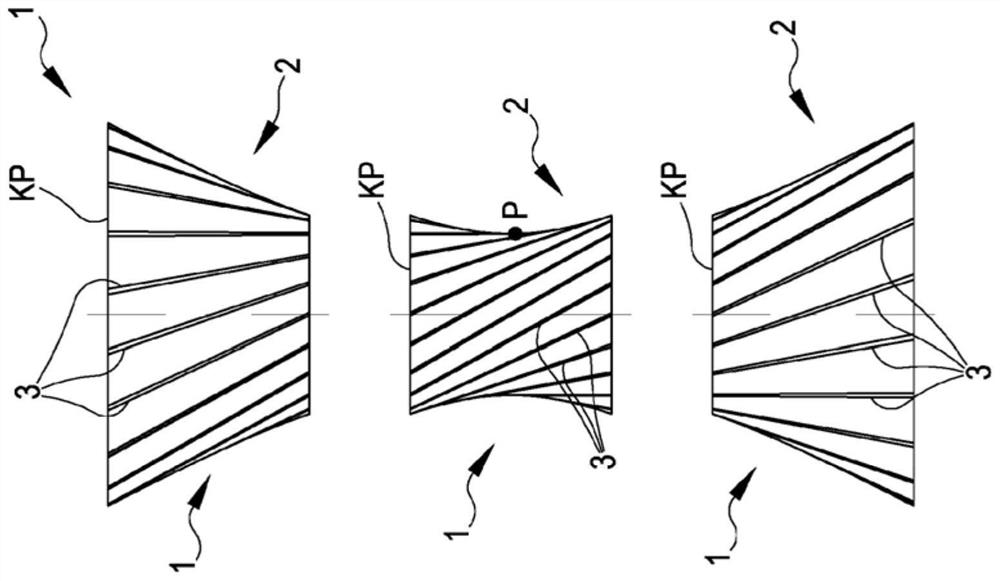

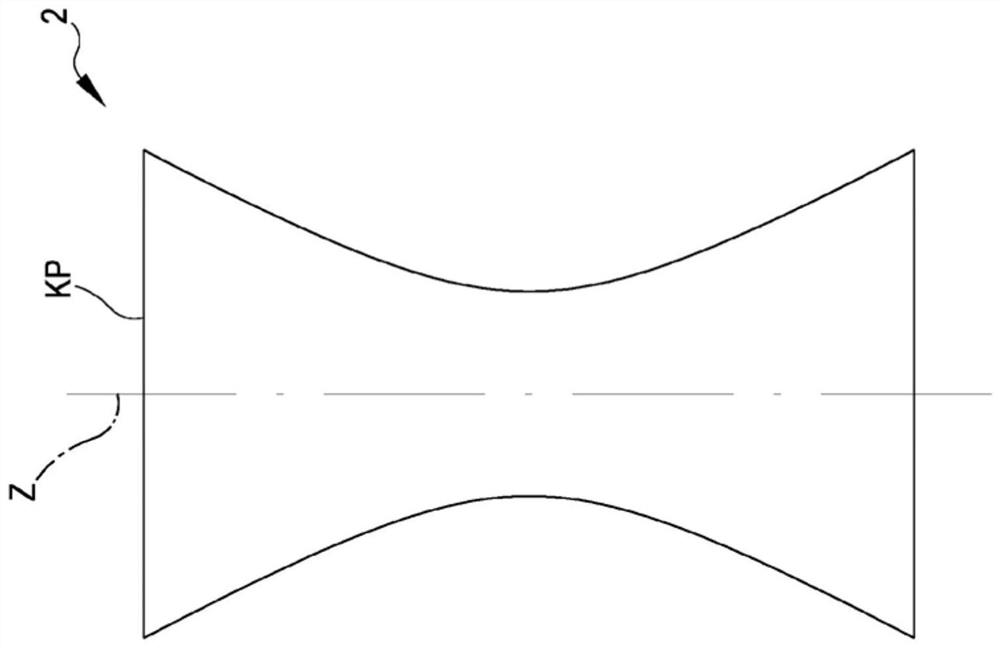

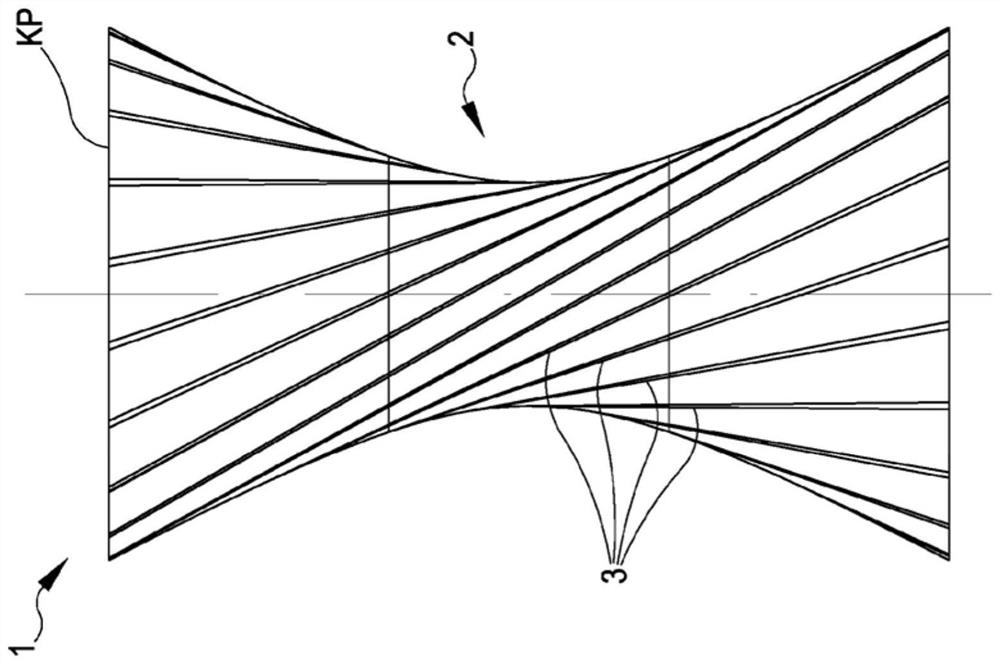

[0125] With reference to the figures mentioned, reference number 1 designates as a whole a needle holding unit for a circular knitting machine according to the invention. In general, the same reference numerals are used for the same or similar elements (if applicable in variants of their embodiment).

[0126] The needle holding unit 1 according to the invention is designed to be introduced into a circular knitting machine for knitted or seamless knitted items or for knitted items. In further elaboration, the needle holding unit is designed to be installed in a circular knitting machine, wherein the circular knitting machine comprises at least:

[0127] supporting structure (or frame);

[0128] the needle holding unit itself, which is rotatably mounted to the frame for rotation about the central axis;

[0129] A plurality of needles, which are supported by the needle holding unit and moved to produce knitted fabric;

[0130] A plurality of yarn feeding points or yarn "feeder...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap