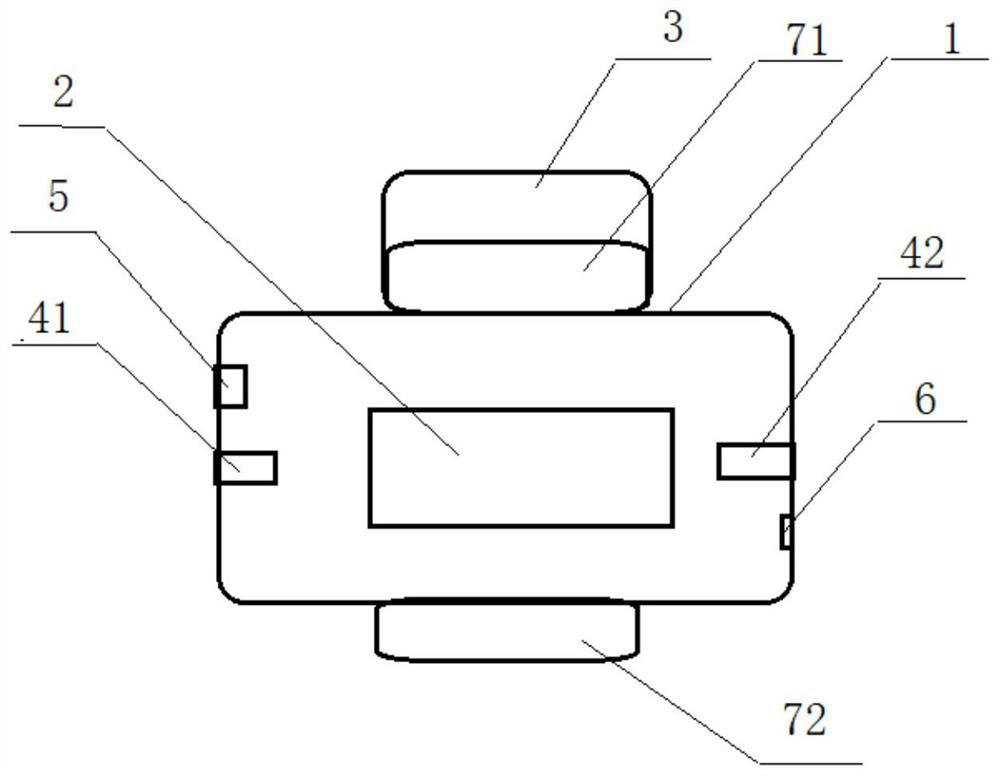

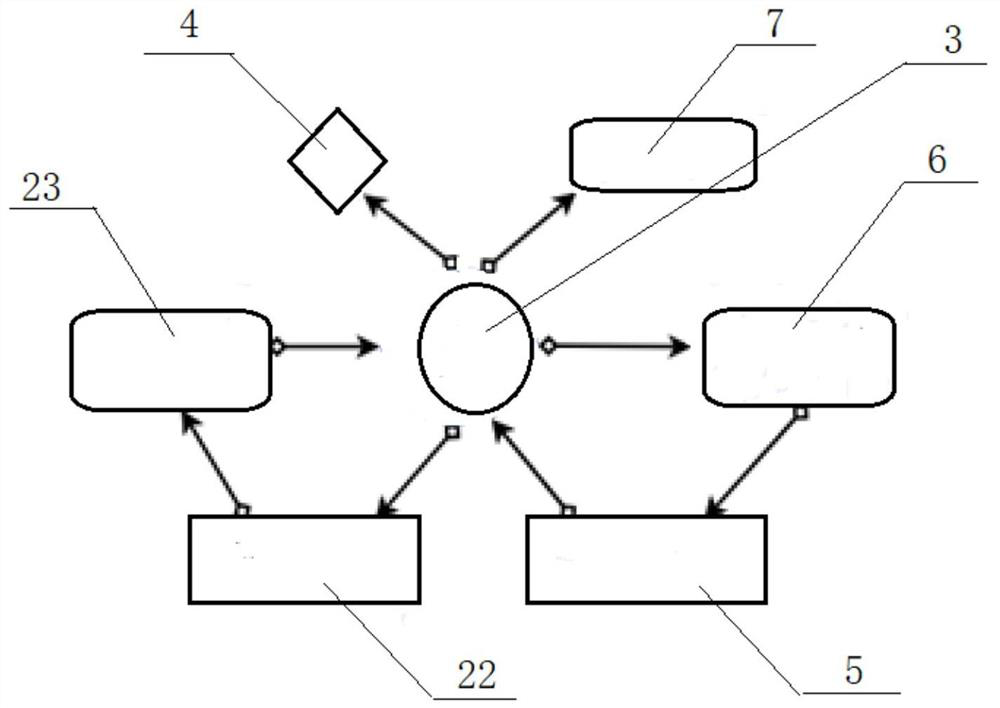

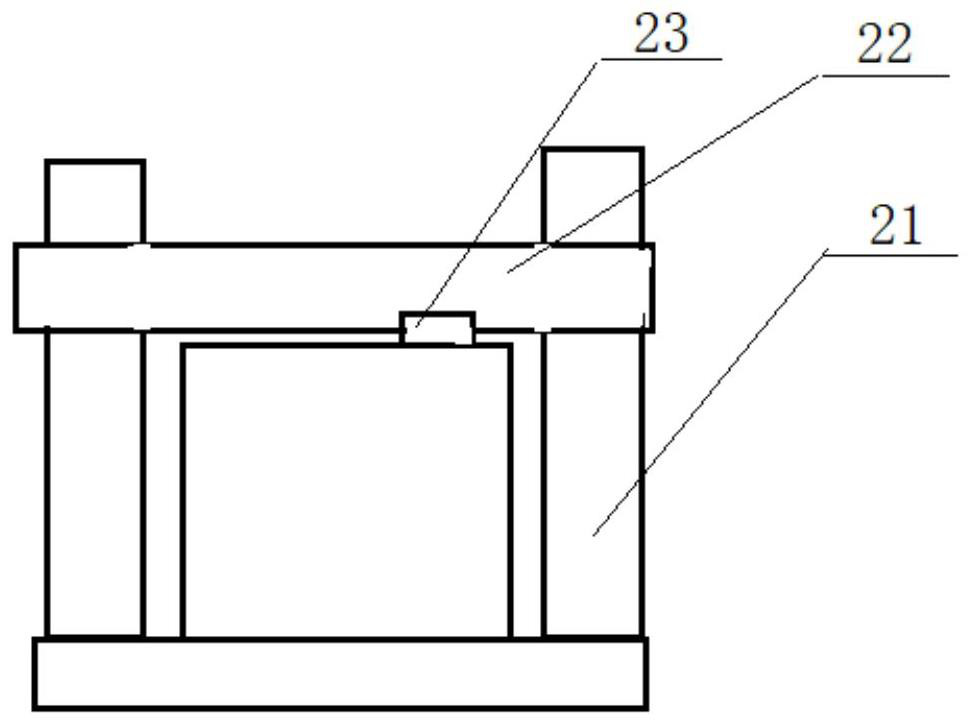

Device for accelerating material corrosion and corrosion performance testing method

A technology of dissolution and performance, applied in the field of metallurgy, can solve problems such as differences, and achieve the effect of accelerating the dissolution process and close test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take the concrete material as an example:

[0057] Devices for accelerating material erosion as provided above may be employed. First prepare the concrete material that meets the specified size, and cut the concrete material into a size of 100mm×100mm×20mm. In order to facilitate loading, the loading force requirement is not very high. Determine the specific value of the load force required to be loaded, which can be determined according to the actual service load stress level of the concrete. Then, prepare the corrosion ion solution, such as corrosion medium ion concentration or use deionized water directly. Determine the solution temperature and flow rate. If it is below 60°C, it can be determined according to the actual concrete service environment temperature. Determine the specific value of the ultrasonic emission frequency, such as the frequency above 40kHz, to ensure the cleaning effect.

[0058] The absolute dry weight, porosity, strength, weight percentage o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap