Electric circular saw

A technology of electric circular saw and saw blade, which is applied to sawing machine devices, metal sawing equipment, attachment devices of sawing machines, etc., can solve the problems of large distance and difficulty in improving the balance performance of electric circular saws, and achieve the effect of good balance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

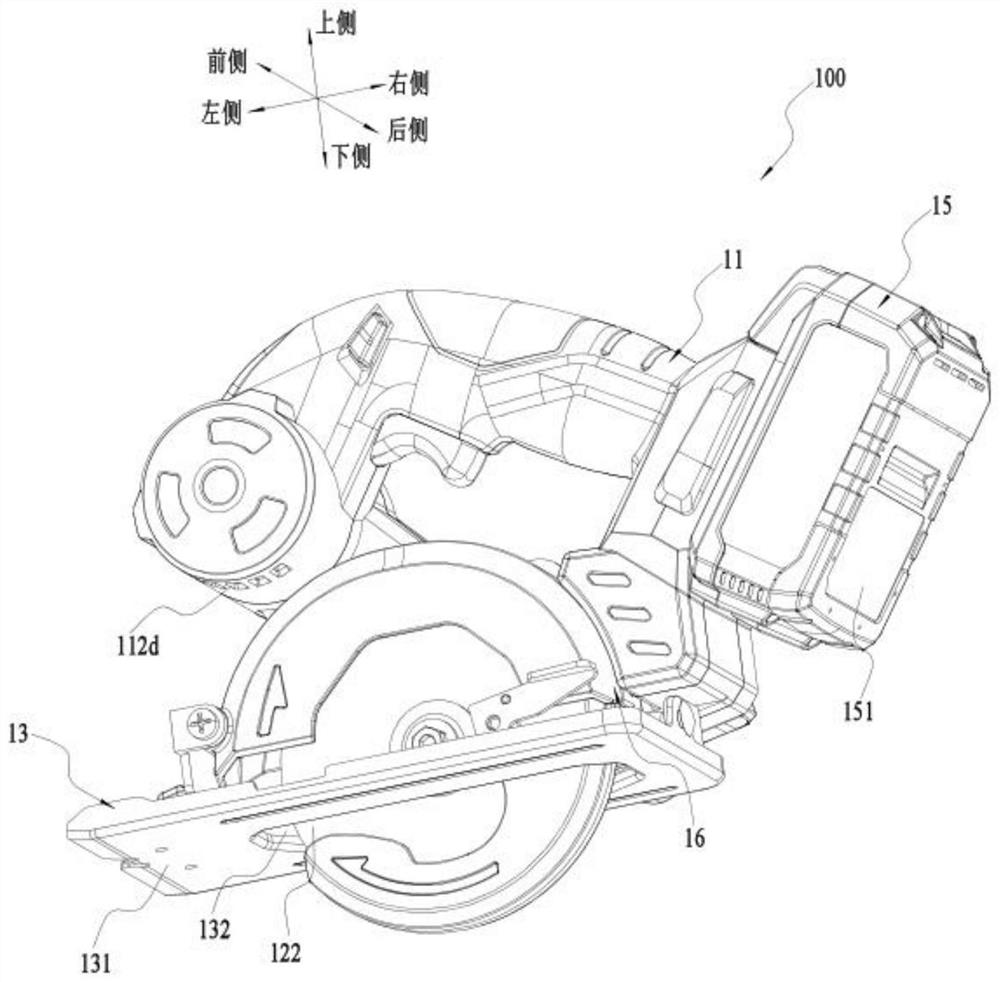

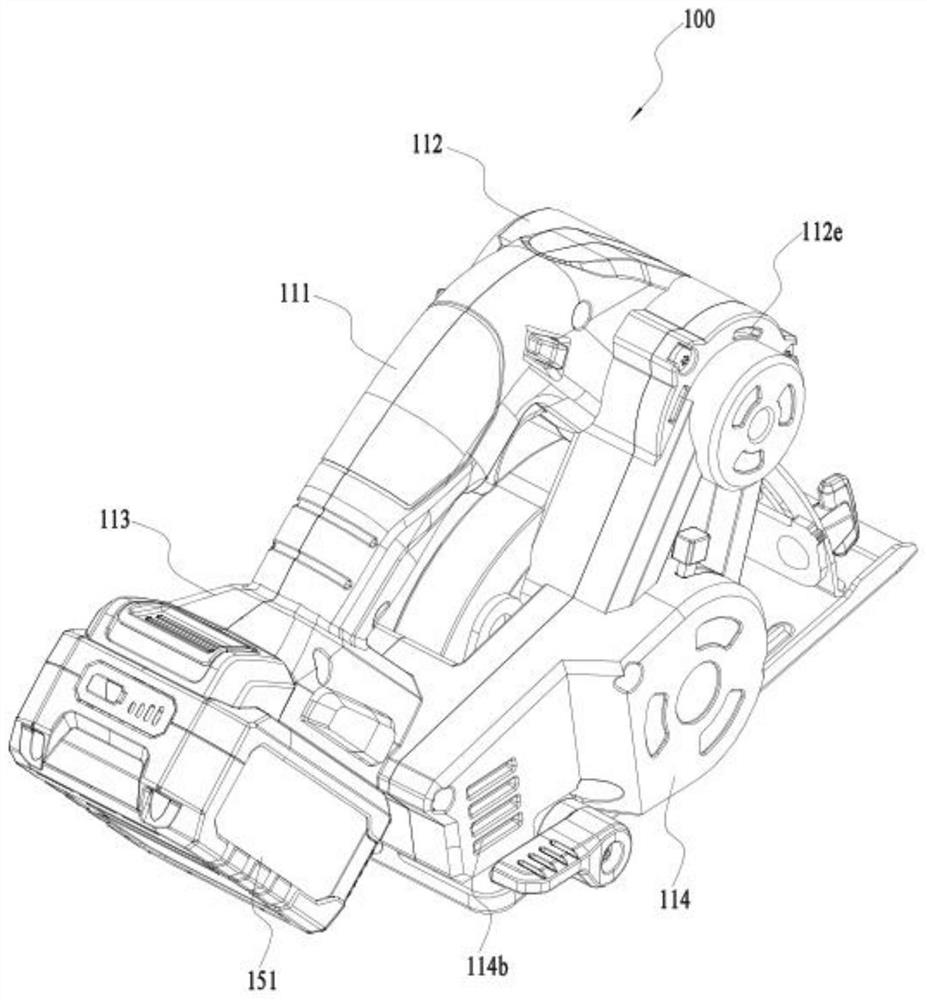

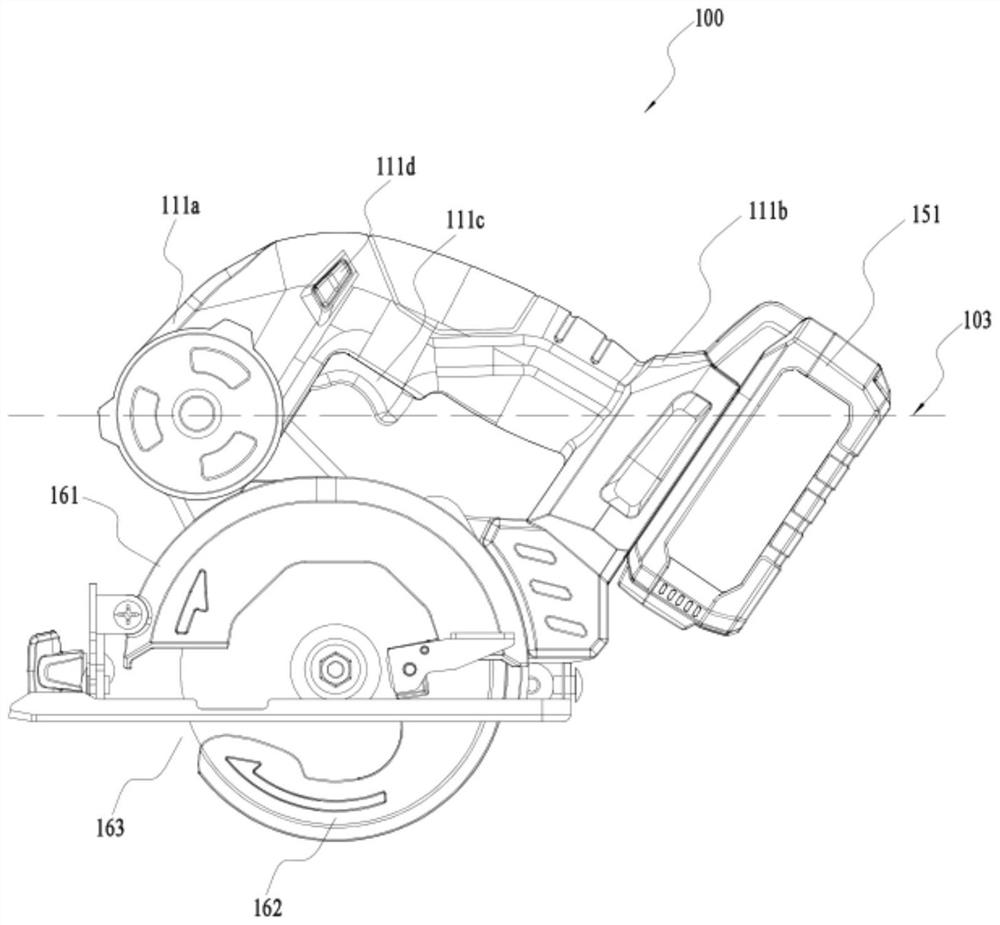

[0041] figure 1 The electric circular saw 100 of the first illustrated embodiment can be used for cutting wood, fiberboard, and plastic, among others. Such as figure 1 and Figure 7 As shown, the electric circular saw 100 includes: a housing 11 , an output shaft 121 , a saw blade 122 , a bottom plate 13 , a motor 14 , and a power supply device 15 . Wherein, the casing 11 is used to accommodate parts such as the motor 14 , and the motor 14 is used to provide a source of power and can drive the output shaft 121 to rotate around the first axis 101 to output power. The saw blade 122 is used to cut the workpiece, and the bottom plate 13 is formed with a bottom plate plane 131 for contacting the workpiece. The power supply device 15 is used to supply power to the motor 14, and the power supply device 15 may be a battery pack 151, or may be an AC power cord.

[0042] In order to facilitate the description of the technical solution of the present invention, it is also defined as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com