Four-way multi-direction automatic orbital transfer track and orbital transfer method thereof

A multi-directional, track-turning technology, which is applied to tracks, roads, buildings, etc., can solve the problems of low mobilization efficiency, single transport direction, low transport efficiency of transport equipment, etc., and achieves stable structure, complete transport logic, high safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

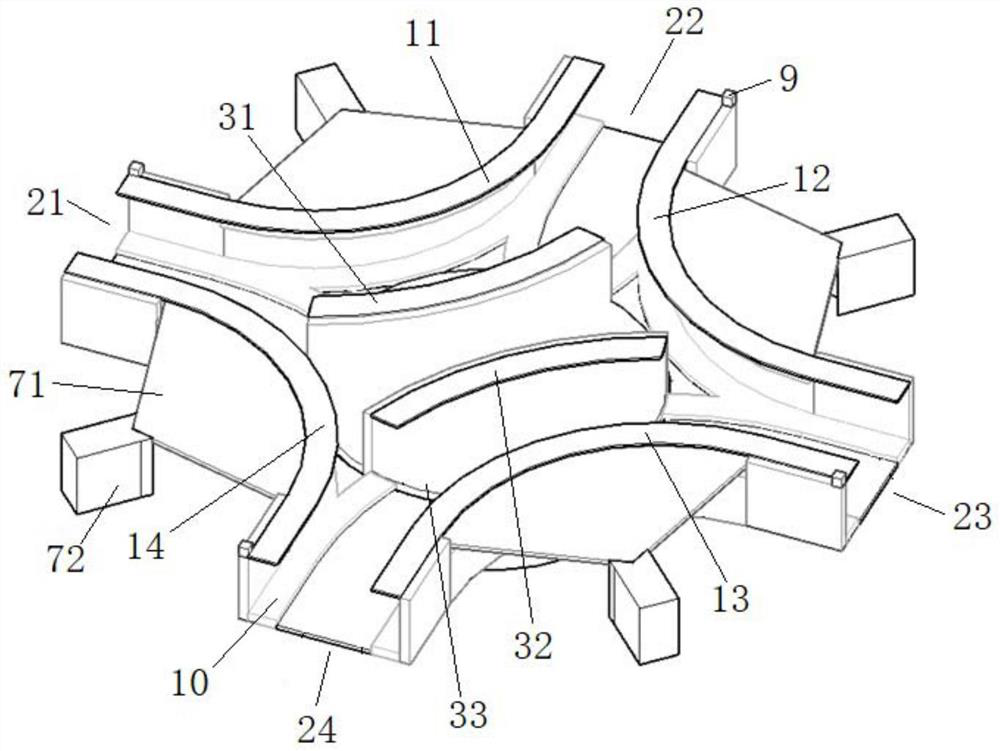

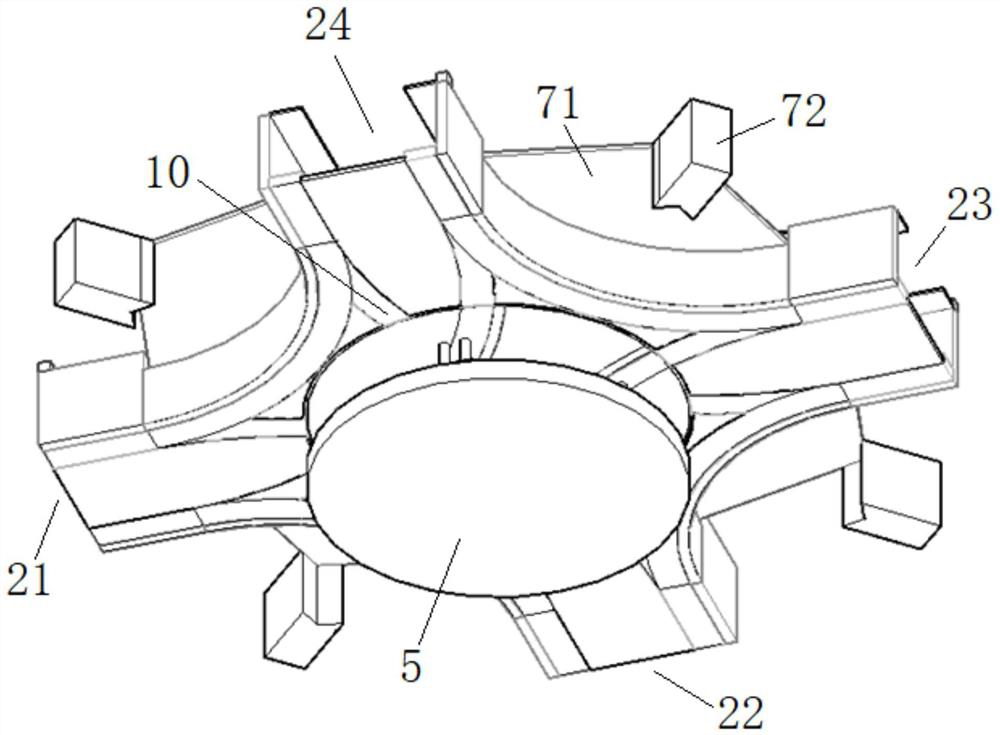

[0047] This embodiment provides a four-way multi-directional automatic track changing track, which can be applied in the field of automated production and logistics, and provides track changeable tracks for logistics trolleys.

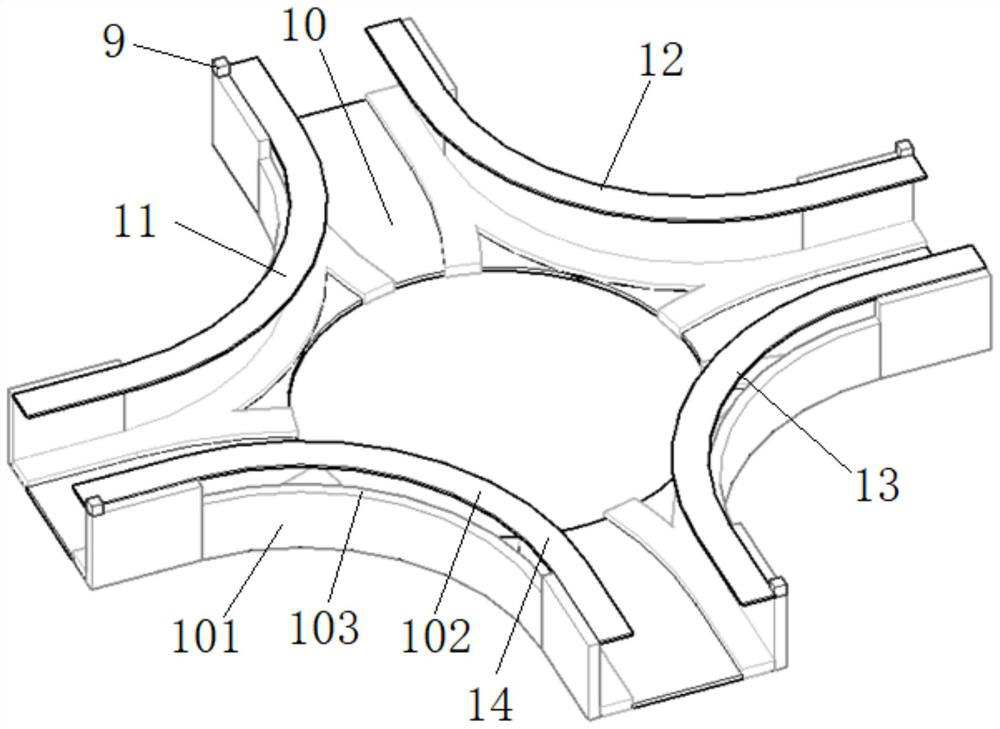

[0048] see figure 1 and figure 2 The track change track includes: a four-way track unit, a rotatable track unit and a controller. In this embodiment, the track change track may also include a mounting seat 5, a drive motor 6, a guide unit, a lifting mechanism and an induction unit 9.

[0049] The four-way track unit includes a bottom section 10 and four arc track sections installed on the bottom section 10 . The four arc-shaped track segments are arranged symmetrically to the center, and the four arc-shaped track segments and the bottom surface segment 10 enclose a "ten"-shaped channel. The corner of the "ten"-shaped channel can be smoothed to facilitate the steering of the logistics trolley. The ends of any two adjacent arc-shaped track sections a...

Embodiment 2

[0075] The present invention also provides a track changing method, which is applied to the four-way multi-directional automatic track changing track in Embodiment 1. The track change method includes the following steps:

[0076] Determine whether the car enters the current basic track. If the trolley enters the current basic track, analyze the current required steering of the trolley according to a transport command, and judge whether the required turning track of the trolley is formed.

[0077] If the steering track required by the trolley is formed, the trolley passes the steering track and turns. If the required turning track of the dolly is not formed, a stop signal is sent to the dolly and the dolly is stopped, and the round table 33 is controlled to rotate to a preset angle corresponding to the required turning track of the dolly.

[0078] Before the dolly enters the desired steering track, it is also judged whether there are other dollies on the steering track. If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com