A three-way wireless power supply track and its track changing method

A track and three-way technology, applied in mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of low mobilization efficiency and single transportation direction, and achieve improved mobilization efficiency, good guiding flexibility, and good dynamic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

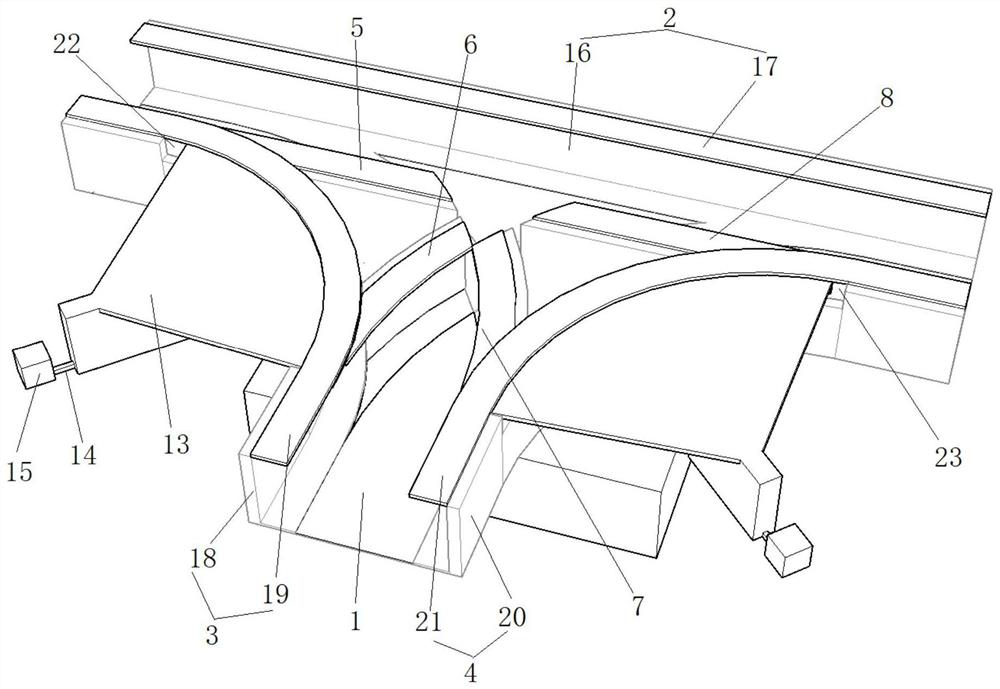

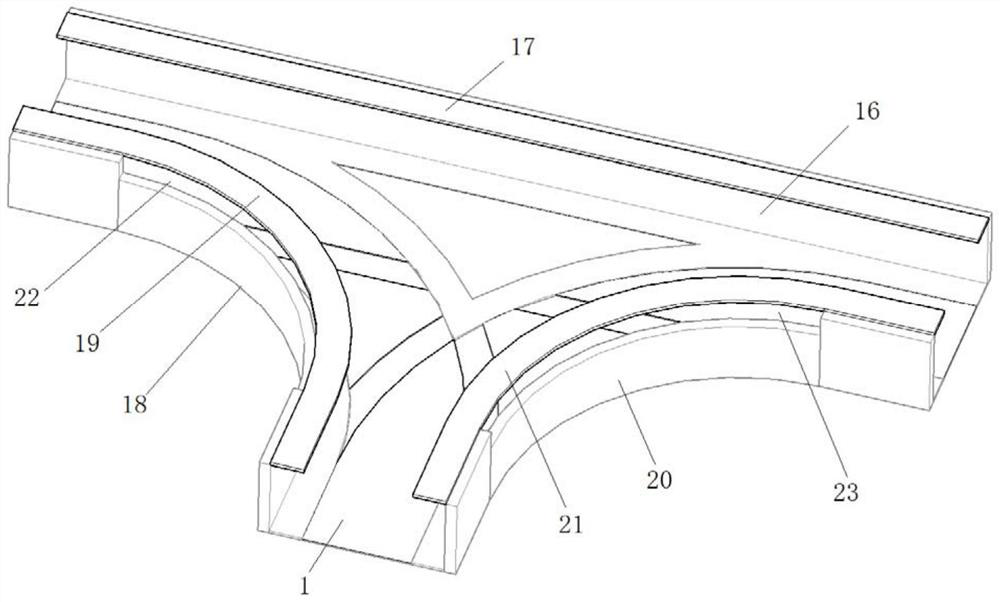

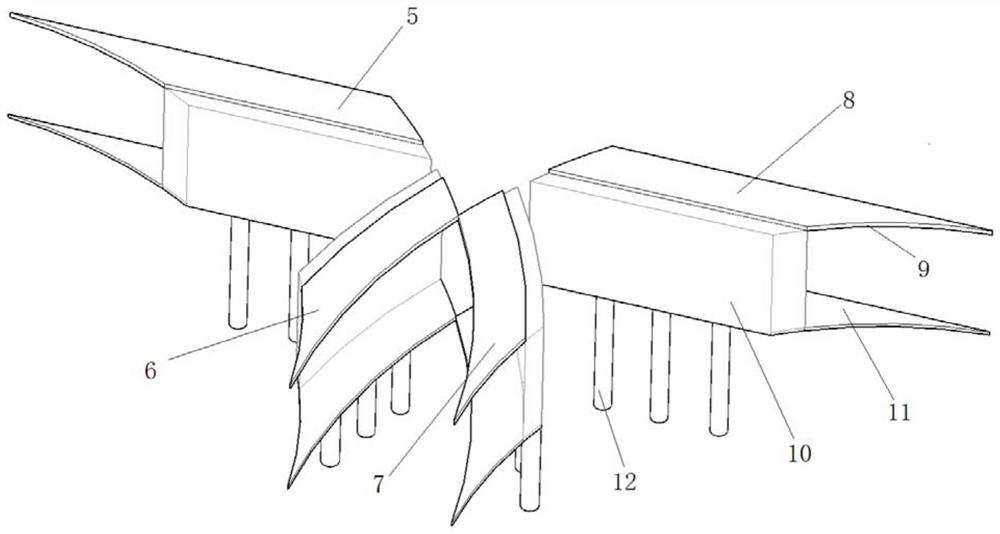

[0047] see figure 1 , the present embodiment provides a three-way multi-directional automatic track changing track, which can be applied in automated production logistics, and provides a track changing track for logistics trolleys. Wherein, the track changing track includes a three-way integral basic track unit, a liftable track unit, a movable guide track unit and a controller.

[0048] see figure 2 , the three-way overall basic track unit includes bottom surface section 1, straight track section 2, arc track section one 3, arc track section two 4, straight track section 2, arc track section one 3, and arc track section two 4 are all installed on the bottom surface section 1, and form a T-shaped channel with the bottom surface section 1. The corners of the T-shaped channel are rounded to make it easier for the trolley to turn. One end of the arc-shaped track section one 3 is arranged parallel to one end of the linear track section 2, and forms a basic track one. The arc ...

Embodiment 2

[0060] This embodiment provides a three-way multi-directional automatic track change track, the automatic track change track is similar to the track change track in Embodiment 1, the difference lies in the control mode of the controller. In this embodiment, the controller determines the channel direction of the trolley on the T-shaped channel according to the position of the trolley and the traveling route of the trolley. There are a total of eight passage directions, namely, base track 1 to base track 2, base track 1 to base track 3, base track 2 to base track 1, base track 2 to base track 3, base track 3 to base track 1, base track 3 to base Track 2, when the car is on one of the basic tracks, it can only travel to the other two basic tracks, and the specific channel direction can be determined based on the travel route and destination. Then, the controller drives the liftable track section in the corresponding channel direction to go up and down to form a straight track or ...

Embodiment 3

[0062] This embodiment provides a kind of equipment for the multi-directional logistics transportation of an automated factory, which includes at least one dolly and a plurality of three-way multi-directional automatic track changing tracks as in Embodiment 1 or 2, and these track changing tracks are the same as the existing ones. The straight track combination forms a rail transportation network, and the trolley runs on the rail transportation network to realize the material handling function. Since the track change track can realize the track change function in six directions, this can greatly increase the number of tracks in the track transportation network, that is, increase the travel path of the trolley, thereby improving transportation efficiency, saving the energy consumption of the trolley, and reducing logistics handling costs .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com