Front-back automatic connecting structure and method for double-track shuttle vehicle

A technology of automatic connection and connection structure, applied in the field of cargo handling, can solve the problems of low efficiency, inconvenience, unstable structure, etc., and achieve the effect of high degree of automation, stable structure, and improved connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

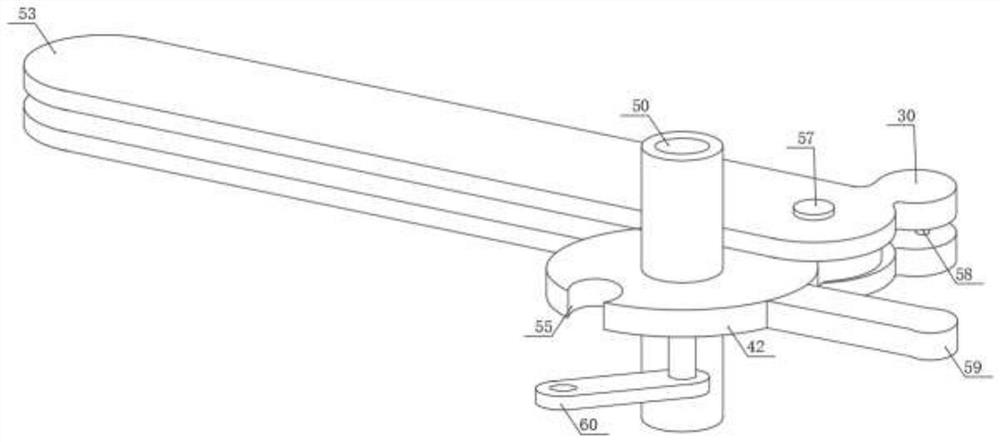

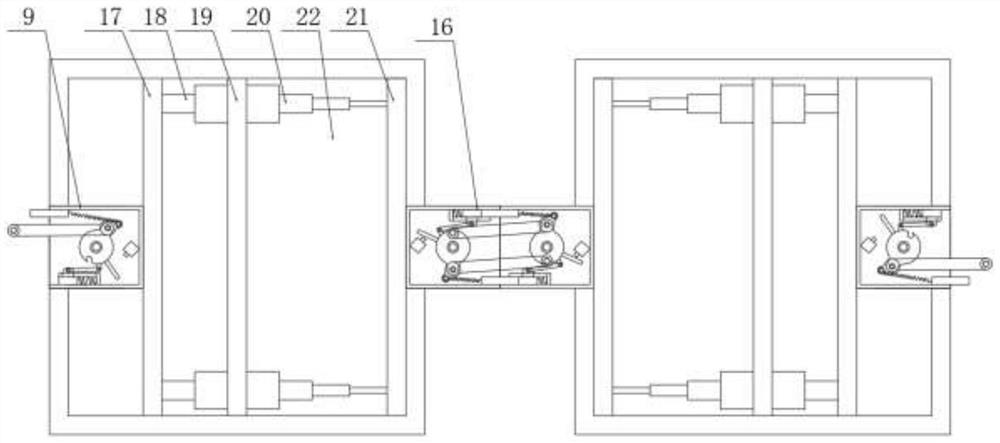

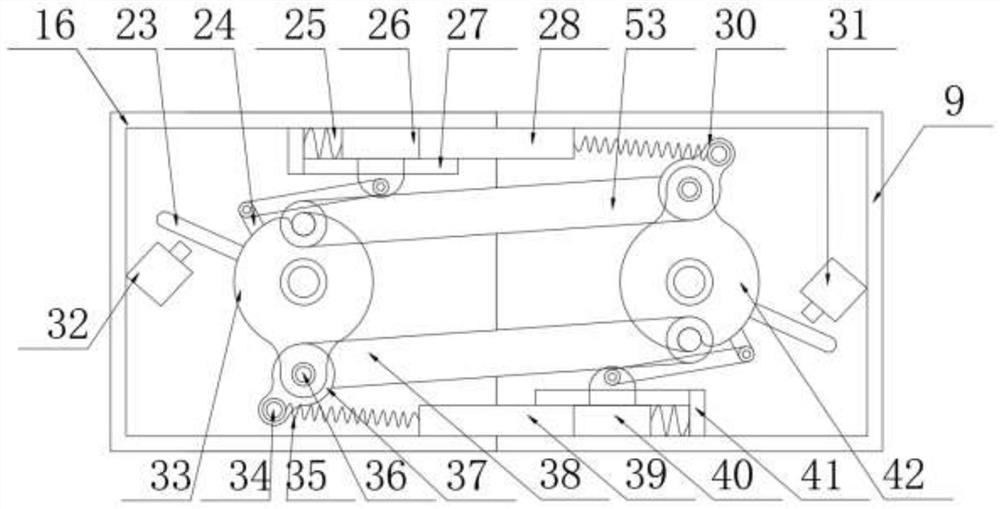

[0037] Example 1, please refer to figure 1 , 2 , 3, 4, 5, 6 and 7, a two-track shuttle, automatic connection structure, and connection method, including double track shuttle base 1, double-track shuttle base 1 fixed connection with double track shuttle body 2, double rail shuttle The surface of the vehicle body 2 has a first passport 10, and the first passage 10 is fixed to the upper side of the first infrared sensor 11, and the double-track shuttle car body 2 has a second opening 15, second. The upper side is fixed to the upper side of the passage 15, and the interior of the double rail shuttle car body 2 is provided with a connection structure storage chamber 22, and the connection structure storage chamber 22 is fixed to the separator 19, and the separator 19 is fixedly connected. There is a first electric push rod 18, and the first electrical push rod 18 is fixedly connected to the first fixing plate 17, and the first fixing plate 17 side surface is fixedly connected to the fi...

Embodiment 2

[0038] Example 2, please refer to figure 1 , 2, 3,4,5,6 and 7 a front and rear automatic connection structure and connecting method of two-track shuttle, the shuttle comprises a base 1 two-track, two-track on one surface of the shuttle base-track shuttle fixedly connected with the body 2, the two-track shuttle 2 a side surface of the carriage body defines a first port 10, a first upper side port 10 is provided with a first fixed infrared sensor 11, the vehicle-track shuttle 2 is another side surface of the body defines a second port 15, a second port 15 is provided on the side of the fixed second infrared sensor 14, two-track shuttle carriage body defines a second inner housing chamber 22 connected to the structure, the internal structure of the housing chamber 22 is connected with partition plate 19 is fixed, the side surface of the separator 19 is fixedly connected first electrical push rod 18, a first end of a first electrical push rod 18 is fixedly connected to the fixing plat...

Embodiment 3

[0039] Example 3, refer embodiment figure 1 , 2 , 3,4,5,6 and 7, the two-track inside the shuttle body 2 is fixedly connected with a lifting cylinder 4, the upper end of lifting cylinder 4 is fixedly connected with a cargo support plate 5, both the top surface 2 of the body are double-track shuttle fixedly connected electric telescopic rod 12, electric retractable rod 12 is fixedly connected at one end with a clamp 13, the two-track shuttle body 2 is fixedly provided inside the processor 3, the two-track shuttle body 2 is provided with an internal lithium battery 6 is fixed.

[0040] Before and after a two-track shuttle automatic connection structure and connecting method:

[0041] S1: Start two shuttle car first infrared sensor and the second infrared sensors, respectively for the two shuttle mutual induction, the preceding vehicle by sensing the second infrared sensor, and start the second electrical drive pusher the second fixing plate motion, further connected to a second stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com