Round tube and U-shaped combined type sealing-tape machine

A composite, tape machine technology, applied in the direction of conveyors, conveyor objects, rollers, etc., can solve the problems of poor sealing, not environmentally friendly, small turning radius, etc., and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

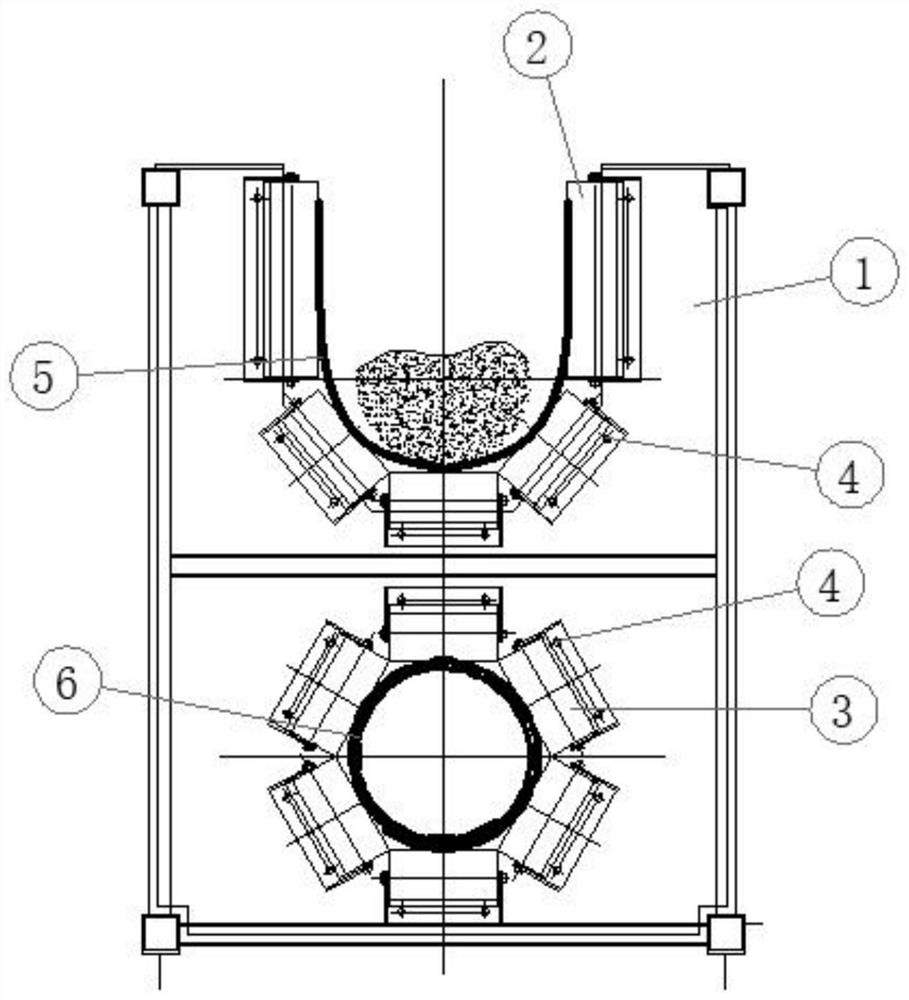

[0015] Such as figure 1 A circular tube and U-shaped composite tape machine is shown, wherein, No. 1 is the fixed bracket, No. 2 is the extended idler, No. 3 is the forming idler, No. 4 is the connecting bolt of the idler, No. 5 is the belt of the bearing section, No. 6 return segment tape. Specific facts: fix serial numbers 2 and 3 on serial number 1 with serial number 4, respectively enclose a U-shaped section for the bearing section, and a circular section for the return section, and then use serial numbers 5 and 6 to pass through the middle to form a A round tube and U-shaped composite tape machine.

[0016] 1. The main principle: design a U-shaped cross section at the material receiving part of the belt conveyor, and design a round pipe cross section at the non-feeding part. The entire belt conveyor line can be changed from U-shaped to circular, and circular to U-shaped, which is very light and convenient. The cross-section form of the tape of the entire line is changed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com