Bidirectional driving device of scraper conveyer and scraper conveyer

A technology of scraper conveyor and two-way drive, which is applied in the field of scraper conveyor and can solve problems such as the failure of scraper conveyor to operate normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

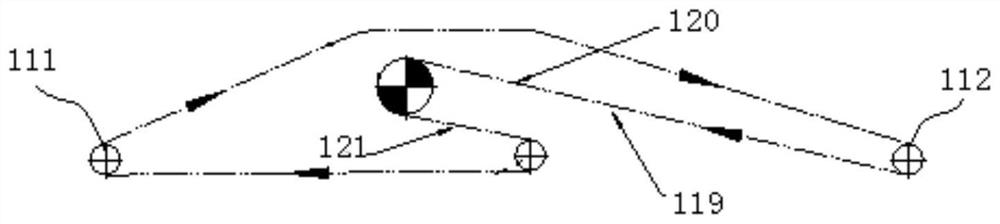

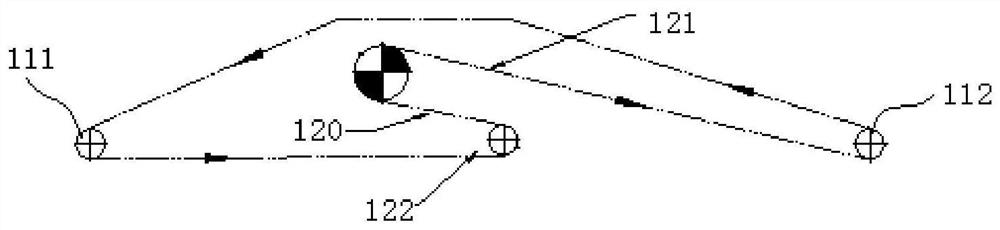

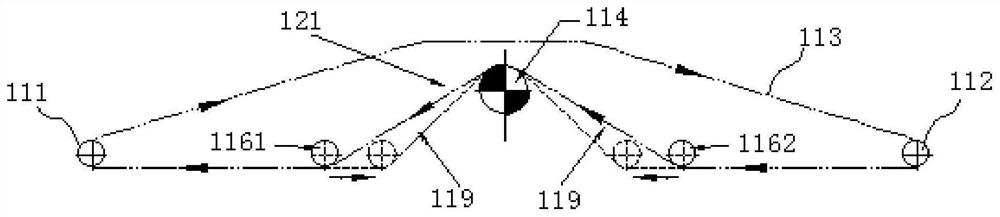

[0039] A two-way driving device for a scraper conveyor, such as image 3 and Figure 4 As shown, it includes a scraper chain 113, a sprocket 114, a drive unit (not shown) and a chain pressing roller.

[0040] The scraper chain 113 is laid from the loading end 111 of the scraper conveyor to the unloading end 112 of the scraper conveyor through the pallet 115, then laid from the unloading end 112 to the sprocket 114, and then laid from the sprocket 114 to the loading end 111, finally forming a closed chain.

[0041]The sprocket 114 is located below the scraper chain 113, and the sprocket 114 is located in the middle between the loading end 111 and the unloading end 112 of the scraper conveyor. The chain winding of the sprocket 114 is improved from the original "S-shaped" layout to "W-shaped". .

[0042] In this embodiment, the drive unit includes a motor, a friction coupler and a reducer, the output shaft of the motor is connected with the friction coupler, the friction coupl...

Embodiment 2

[0050] This embodiment is a scraper conveyor, including the bidirectional driving device of the scraper conveyor in Embodiment 1.

[0051] When the scraper conveyor in this embodiment is in use, the drive unit is started, and the drive unit drives the sprocket 114 to rotate, thereby driving the scraper chain 113 to run. When reverse transport is required, the loose side 121 of the scraper chain 113 is adjusted by the first pusher unit 1171 or the second pusher unit 1172 , so that the scraper chain 113 at this position can be moderately tensioned and well meshed with the sprocket 114 . And the driving device in the present invention does not need to use other sprocket 114 tensioning devices, the driving device can be placed in the middle of the scraper conveyor, and two-way transportation can be realized at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com