Improved structure of sliding sleeve of linear motor rotor

A technology of linear motors and sliding sleeves, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of affecting the performance of linear motors, reducing the working efficiency of linear motors, and large magnetic flux loss of movers, so as to maintain high efficiency, The effect of maintaining performance and maintaining magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

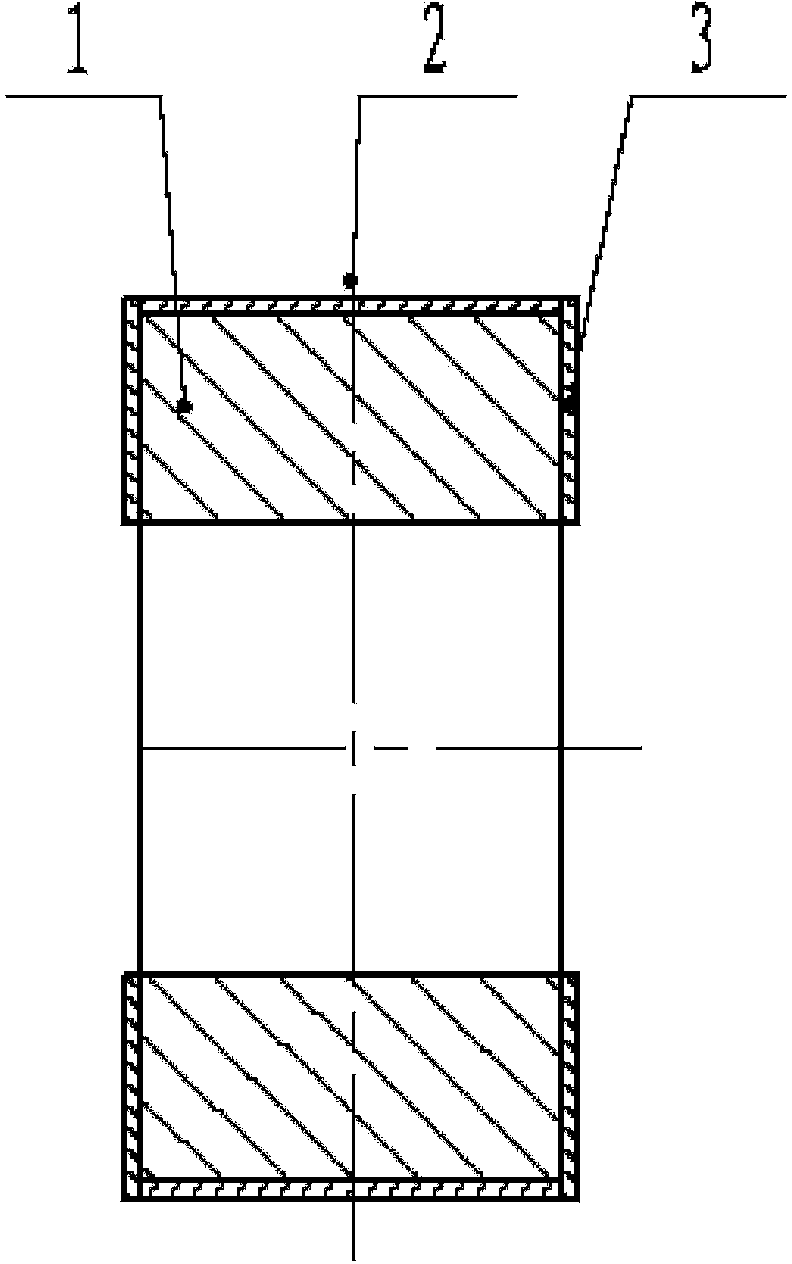

[0012] See figure 1 The improved structure of a sliding sleeve of a linear motor mover shown includes a sliding sleeve 1 . In the present invention, a nickel-based alloy layer 2 is provided in the radial direction of the sliding sleeve 1 , and a non-magnetic material protective layer 3 is provided on two parallel end surfaces of the sliding sleeve 1 . Therefore, the wear resistance and corrosion resistance of the sliding sleeve 1 and the service life of the linear motor can be improved through the nickel-based alloy layer 2 . In addition, the magnetic induction lines can be effectively separated by the protective layer 3 of the non-magnetic material, and the strength of the magnetic field can be maintained when the matching magnetic steels are arranged alternately, so that the motor can still maintain high-efficiency working performance under high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com