Manufacturing method of three-dimensional axisymmetric smooth curved surface internal crack

A production method, axisymmetric technology, applied in the field of production of internal cracks in three-dimensional axisymmetric smooth surfaces, it can solve the difficulty of controlling the direction of fracture, the difficulty in the rate and direction of internal crack propagation, and the inability to produce crack samples in three-dimensional curved surfaces, etc. problem, to achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example specifically illustrates the method of making inclined inner cracks in a glass cube sample. Among them, the glass cube sample is made of K5 glass or K9 glass, and the material of the triangular column block used must be exactly the same as that of the sample.

[0042] The method comprises the steps of:

[0043] S1: Design a layer of circular lattice in the plane where the central position of the glass cube sample is inclined to the upper and lower surfaces of the glass at a certain angle α, and record the three-dimensional coordinates of the lattice at each coordinate point. α≠0.

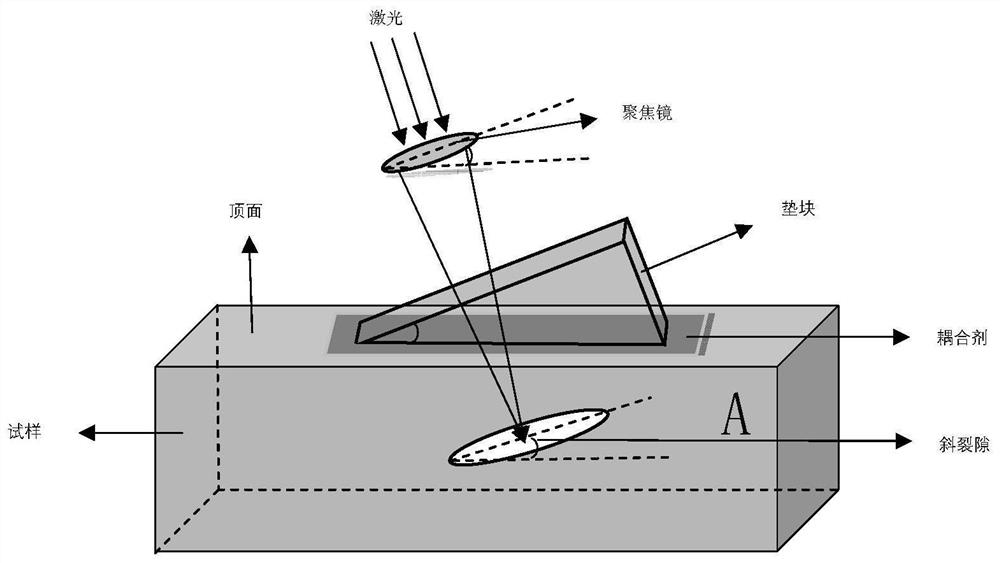

[0044] S2: According to the direction of the inclination angle of the crack in the desired product, calculate the incident direction of the laser, the placement angle of the triangular irregular spacer, and the relationship between the crack tip A and the top surface. The specific operation is as follows:

[0045] The layout of the device structure is as follows figure 2 As ...

Embodiment 2

[0054] This embodiment specifically illustrates the method of making curved surface internal cracks in the glass cube sample with inclined internal cracks produced in Example 1. (In this example, α=60°, the size of the glass cube sample is 40 mm×40 mm×100 mm, and the material is K9 glass)

[0055] S1: Put the prefabricated glass cube sample with inclined internal cracks into the oven, slowly raise the temperature in the oven to 105°C, control the heating rate of the oven at about 4°C / min, heat it to 105°C and keep it warm for 12 hours.

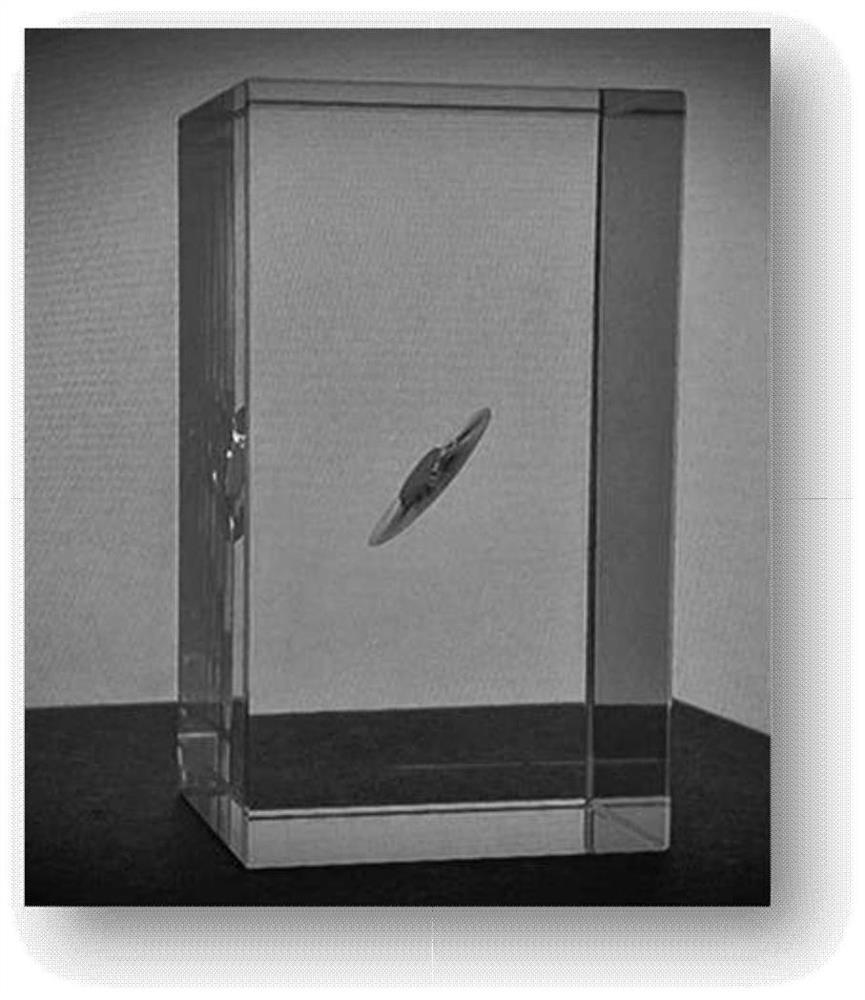

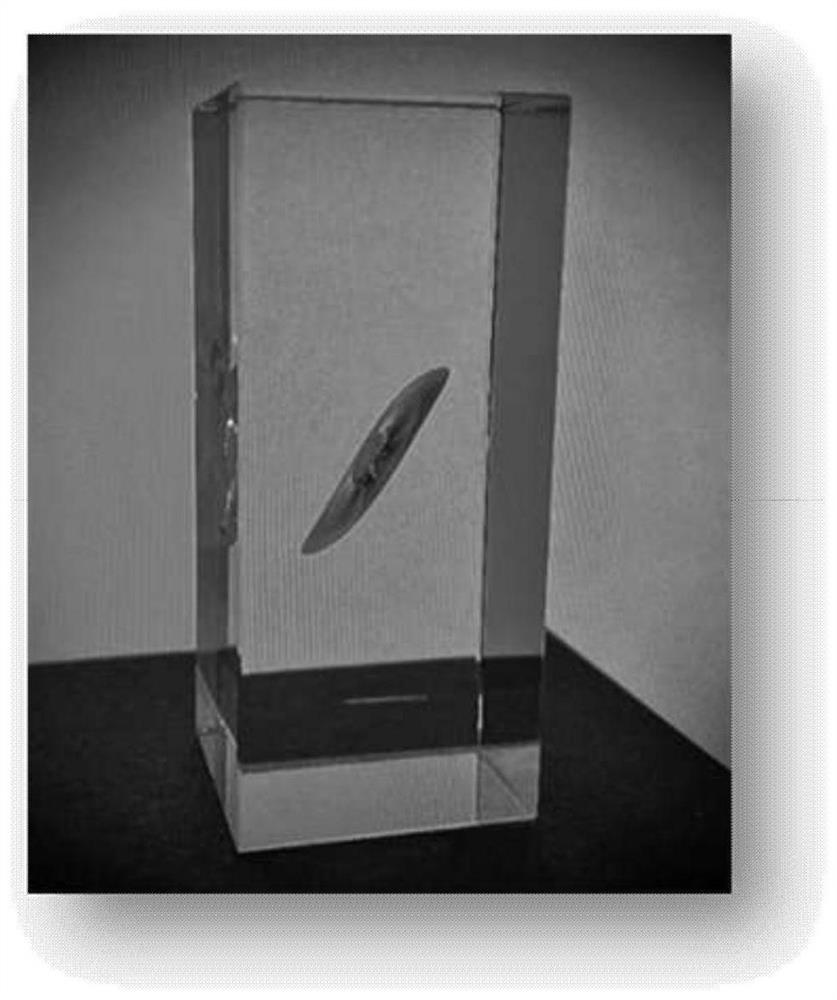

[0056] After heat treatment, the crack tip A close to the top surface bends in the direction opposite to the incident direction of the laser. The bending angle of point A is controlled by the α angle ( Figure 3-4 ).

[0057] S2: Stop the heat preservation, take the glass cube out of the oven and place it at room temperature until it is completely cooled, and observe that the internal oblique cracks have grown into cracks in a three-dimensio...

Embodiment 3

[0059] This example specifically illustrates the influence of different maximum temperatures on cracks in curved surfaces.

[0060] According to the method of Example 1, a glass cube sample of 40 mm × 40 mm × 100 mm was made, α = 60°, the diameter of the failure zone was 8 mm, and the diameter of the expansion ring was 20 mm.

[0061] According to the method of Example 2, the glass cube sample was heat-treated, and the temperature was raised to 70, 80, 90, 100, 110, and 120° C. at a heating rate of 2° C. / min and kept warm. The cracks in the curved surface at the maximum temperature of 120°C are as follows: Figure 5 As shown, it can be seen that as the inner crack propagates, the inclination angle α of the crack tip gradually decreases (crack propagation tends to be parallel to the upper and lower surfaces of the sample).

[0062] Invert the lower half curve by 180°C and compare it with the upper half curve, as shown in Figure 6 As shown in , it can be seen that the expande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com