Two-time groove broaching high-layer stoping mining method

A mining method and trough-drawing technology, which are applied in ground mining, underground mining, special mining, etc., can solve the problems of safe processing time field, many mining process cycles, and small mining height, so as to reduce mining cost and cycle times , Increase the effect of recovery height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

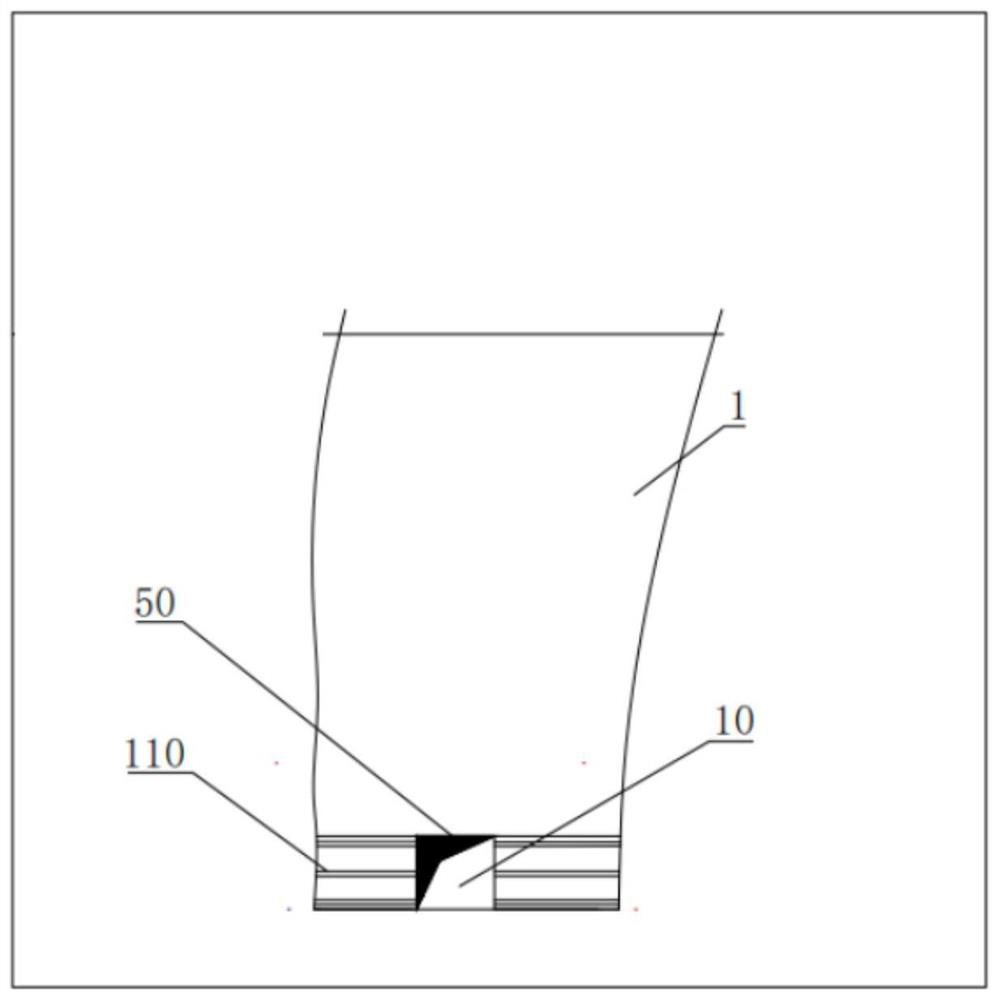

[0032] The invention expands the compensation space of the stope by carrying out one horizontal blasting and two upward blasting in the pulling groove area arranged at the end of the stope, and increases the mining height during mining. Next, the double channeling and high-layer back mining method of the present invention will be described for a thinner (2-10 meters) ore body above an inclination.

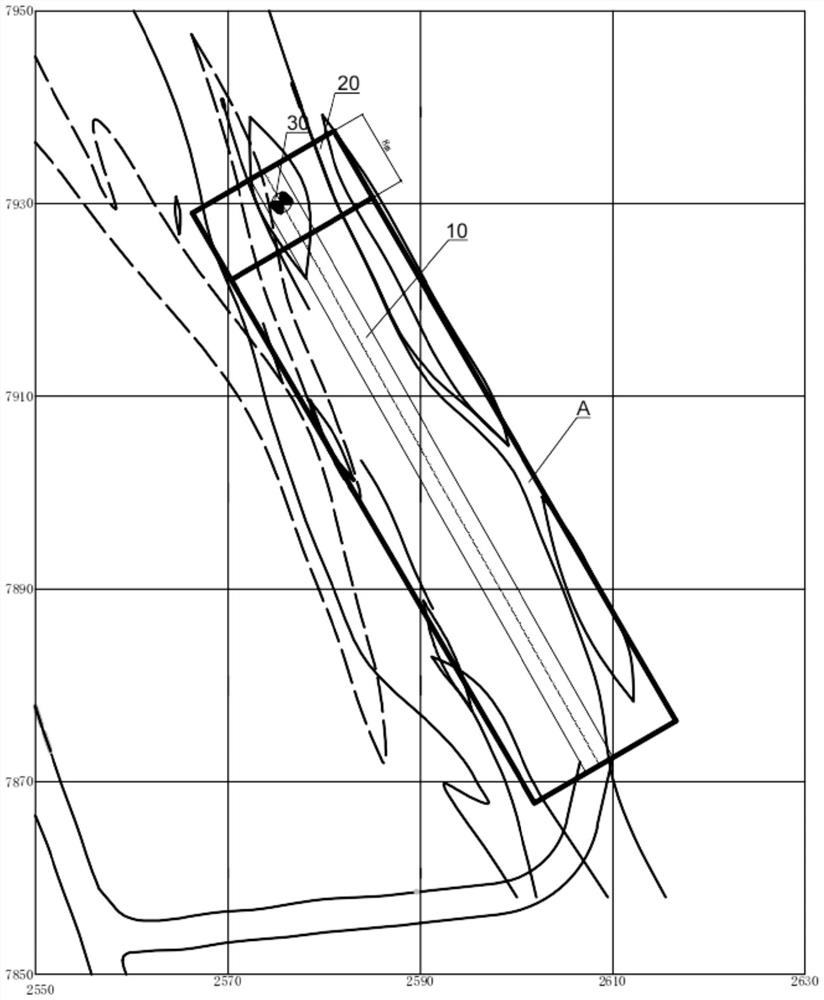

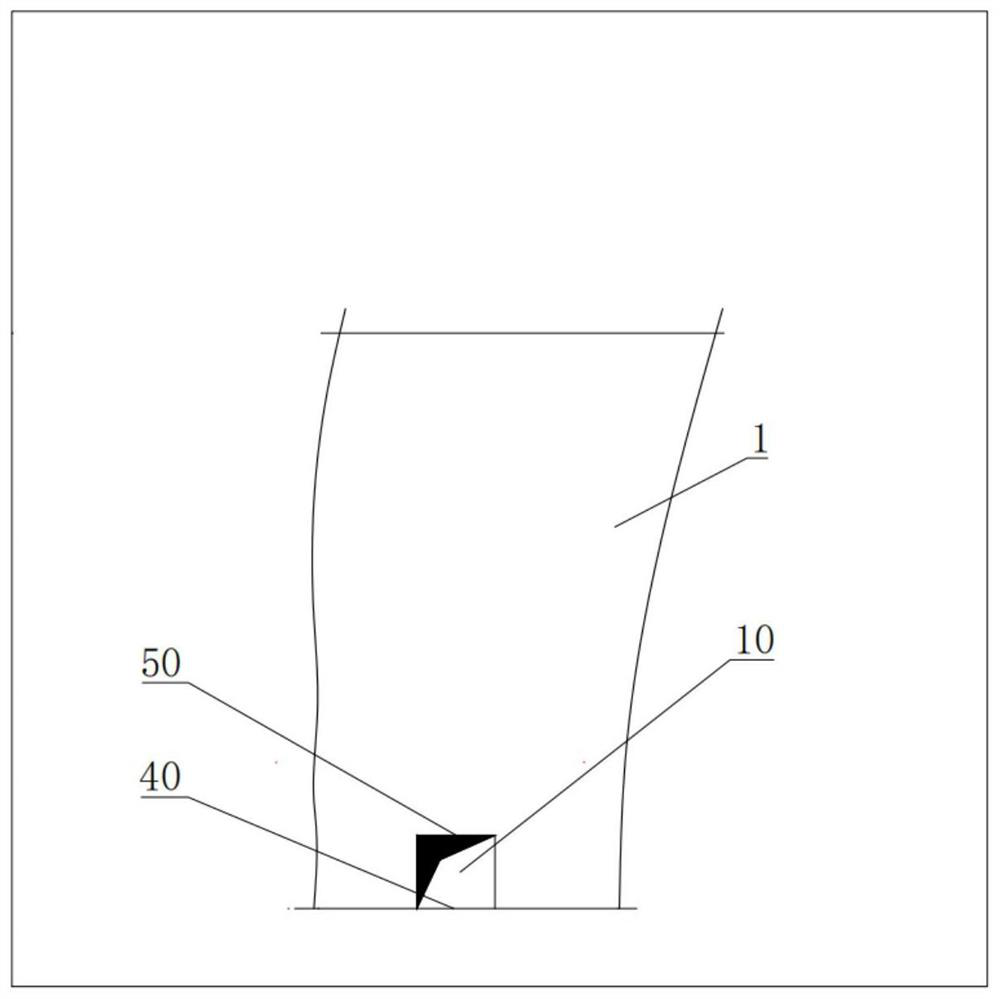

[0033] Bottom pull groove: see figure 1 and figure 2 , figure 1 For being applicable to the top view of the stope of the high-layered back mining method of twice drawing slot of the present invention, figure 2 It is a transverse sectional view of the groove area at the end of the bottom lane of the present invention. It can be seen from the figure that before mining, a control line is set for the ore body along the ore body trend, and the range of stope A is delineated. In the stope A, excavate the mine road along the direction of the ore body 1 to the end of the ore body 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com