Retreating type multi-layer stoping mining method for ore body with inclination from thin to medium thickness

A mining method and a back-up technology, applied in the field of back-up multi-layered mining, can solve the problems of many layers, many turquoise support work, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

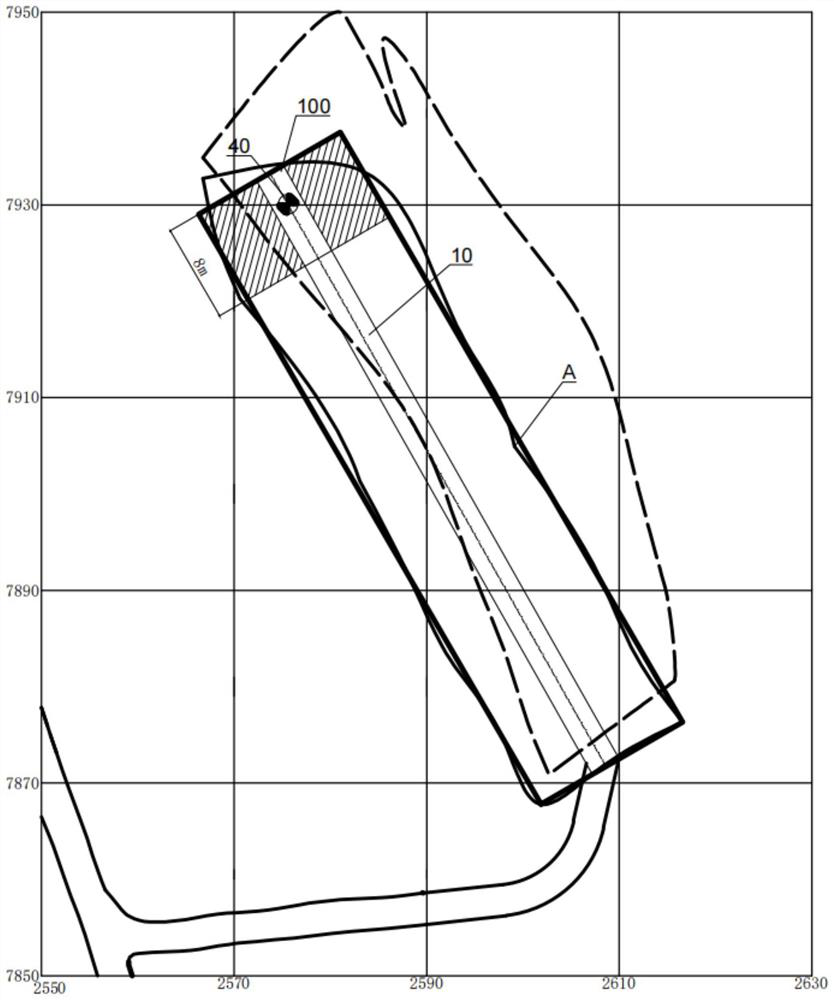

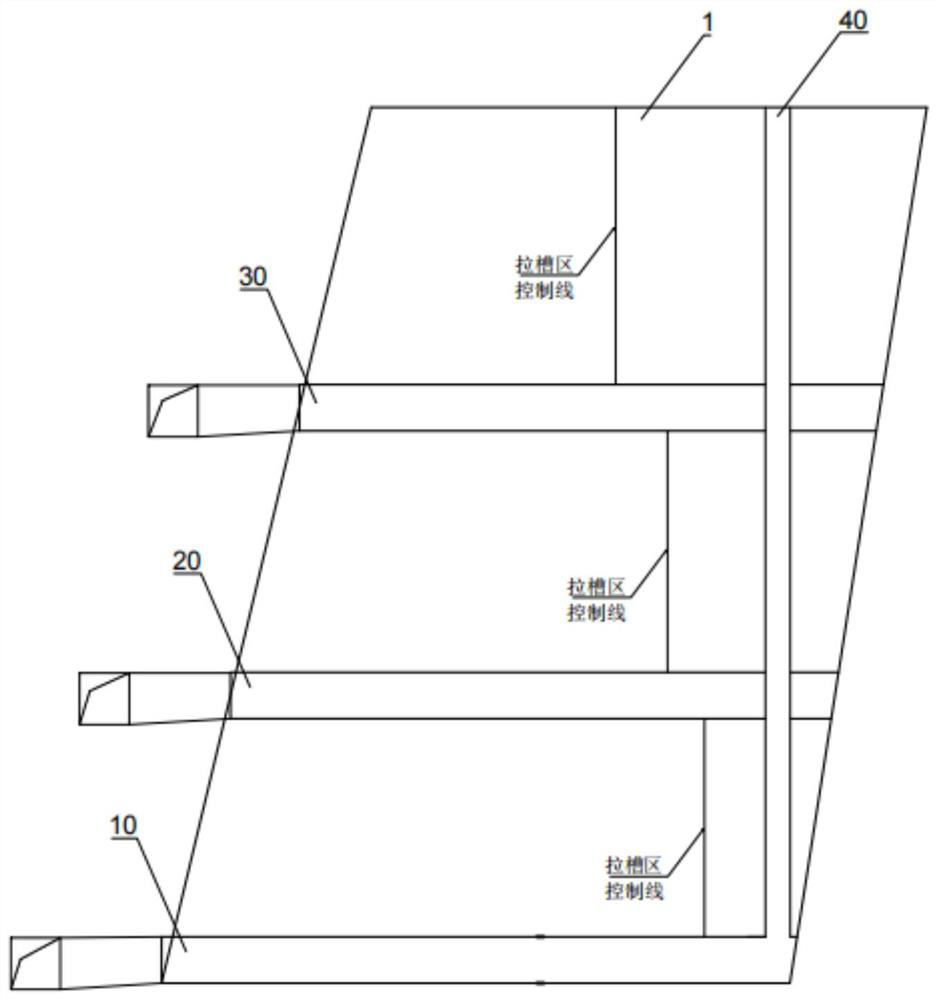

[0039] see figure 1 , figure 1 It is a top view of a stope suitable for the receding multiple layered mining method of thin to medium-thick ore bodies above the slope of the present invention. It can be seen from the figure that before mining, a control line is set for the ore body along the ore body trend, and the range of stope A is delineated.

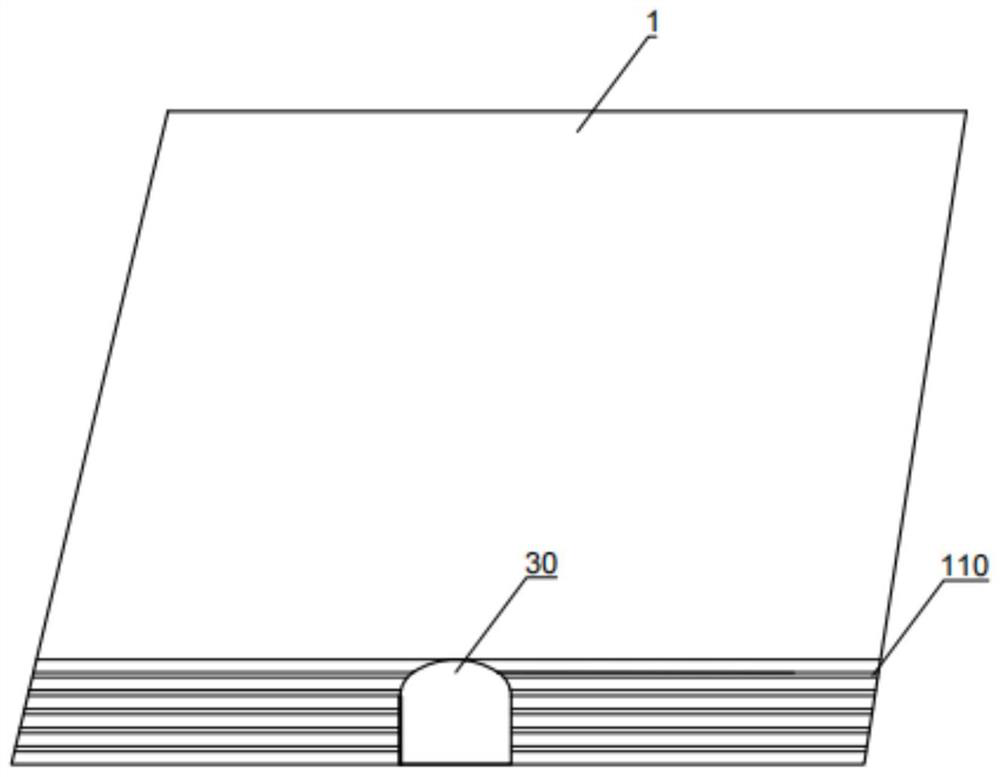

[0040] Bottom tunneling: excavate the ore body 1 to the end of the ore body to form a bottom roadway 10, and set a certain length of bottom roadway 10 from the end of the bottom roadway 10 as the bottom roadway trough area 100. It should be noted that the direction of the bottom roadway can be the same as that of the ore body, or it can be perpendicular to the direction of the ore body. body in the same direction.

[0041] Construction patio: construct a patio 40 up to the upper middle section from the roof of the trough area 100 of the pull bottom lane, which is used as a ventilation channel and a cutting slot to provide a free...

Embodiment 2

[0051] The main steps of the mining method in this embodiment are the same as those in Embodiment 1, the only difference being that the sequence of blasting is different when the slotting area is raised twice, specifically:

[0052] In this embodiment, when the channeling area is raised twice, the first raising of the channeling area 300 of the second rock drilling road located on the uppermost layer is carried out, specifically the channeling area 300 of the second rock drilling road. Construction of multiple first upward blastholes 120 on the top plate to the first design height, the first design height is 6m, and multiple first upward blastholes 120 are charged and blasted, and the ore is transported out after blasting ; Then carry out the first elevating on the first rock drilling lane trough area 200 ;

[0053] Then carry out the second elevation to the second rock drilling lane slotting area 300 located on the uppermost layer, specifically to construct a plurality of fir...

Embodiment 3

[0055] The main steps of the mining method in this embodiment are the same as those in Embodiment 1, the only difference being that the sequence of blasting is different when the slotting area is raised twice, specifically:

[0056] In this embodiment, when the channeling area is raised twice, the channeling area 300 of the second rock drilling road, the channeling area 200 of the first rock drilling road and the channeling area 100 of the bottom roadway are raised for the first time at the same time. Specifically, constructing a plurality of first upward blastholes 120 to The first design height, the first design height is 6m, and simultaneously to a plurality of the first rock drilling roadway dragging area 300, the first rock drilling roadway dragging area 200 and the bottom roadway dragging area 100 Charge the gun hole 120 and carry out the blasting, and the ore is transported out after the blasting.

[0057] Then carry out the second elevation to the slotting area 300 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com