A precise spatial positioning puncture device

A space positioning and equipment technology, applied in puncture needles, inoculation ovulation diagnosis, medical science, etc., can solve problems such as puncture needles mistakenly puncture blood vessels, affect curative effect, and impure tumor target area ablation, and achieve the effect of overcoming amplification errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

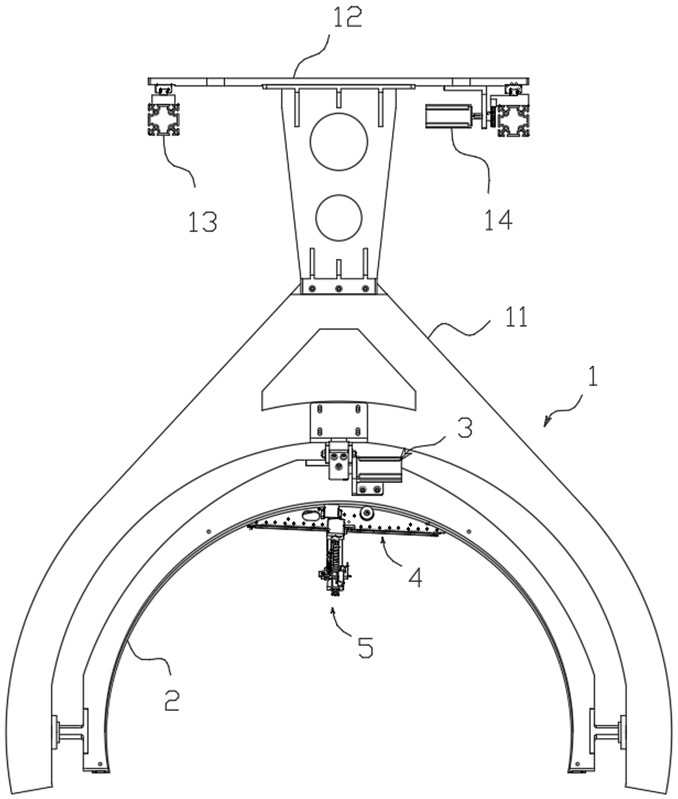

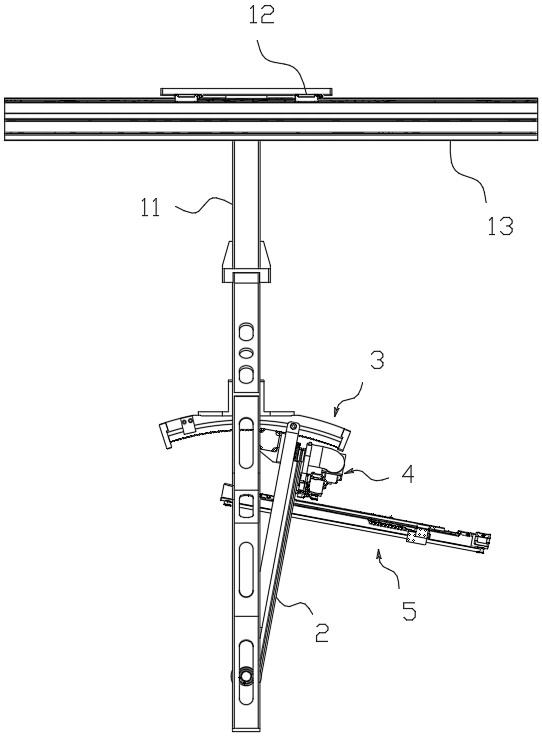

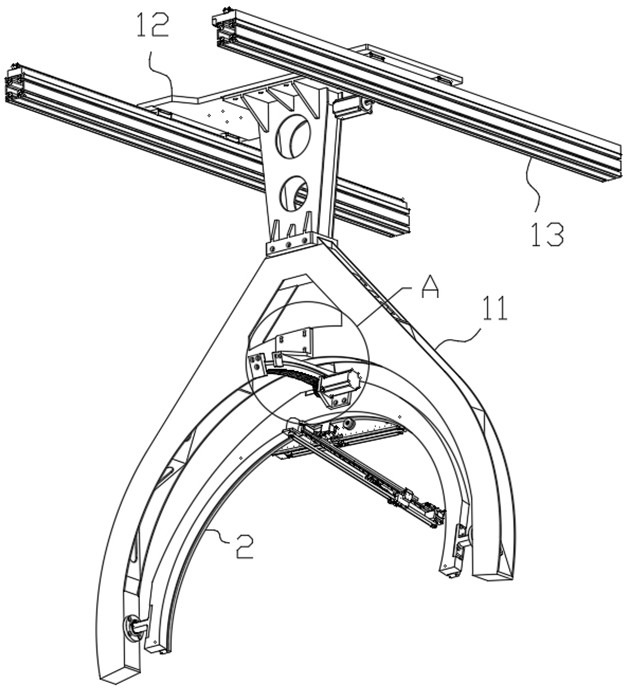

[0042] Combined with the manual Figure 1-Figure 4 The precise spatial positioning puncture device shown is composed of a positioning puncture mechanism with four-axis compound motion and an installation mechanism for installing the positioning puncture mechanism. The positioning puncture mechanism consists of an arc arm 2, a pitch mechanism 3, a deflection Mechanism 4 and mobile mechanism 5 are composed;

[0043] Both ends of the arc arm 2 are hinged on the installation mechanism 1, the pitch mechanism 3 is driven to connect the arc arm 2 and the installation mechanism 1, and the deflection mechanism 4 is slidably arranged on the arc arm 2 , the moving mechanism 5 is slidably arranged on the lower part of the deflection mechanism 4, a reciprocating needle holder 54 is installed on the moving mechanism 5, and the needle holder 54 has at least one needle holder. The arc arm 2 is arranged in a semicircle, and the axis where the hinge point of the arc arm 2 and the mounting seat...

Embodiment 2

[0047] This embodiment is a further detailed design for the pitch mechanism 3 in terms of the structure and principle of the embodiment 1, and it is also one of the two technologies of the application. Specifically, the pitch mechanism 3 includes fixed installation on the installation The second rack 31 on the mechanism 1 and the second servo motor 32 installed on the arc arm 2, the second servo motor 32 is drivingly connected to the second rack 31 through a second drive gear 33; The plane where the second rack 31 is installed is perpendicular to the plane where the arc arm 2 is located. The key point of the puncture device is the accuracy of puncture. When pitch adjustment is required, if a conventional hinged shaft is used for driving, it will have an error amplification effect on the needle holder 54, that is, because the needle holder 54 is the final installation of the puncture needle. structure, its spatial position is affected by the size and sliding position of the mov...

Embodiment 3

[0053] On the basis of embodiment 2, further in conjunction with specification sheet Figure 5-Figure 9 As shown, this embodiment also refines the structure of the deflection mechanism 4 and the moving mechanism 5 respectively. Specifically, the second sliding rail 21 and the arc rack are fixedly installed on the arc arm 2, and the deflection The mechanism 4 is slidably installed on the second slide rail 21, the deflection mechanism 4 includes a first bracket 41, a third servo motor 43 installed on the first bracket 41, and is used to clamp the second slide rail 21. A roller 42 and a third slide rail 48 for installing the moving mechanism 5, the positions at both ends of the third slide rail 48 above the first support 41 are respectively provided with fourth slide rails connected by the first anti-skid belt 45. Servo motor 44 and first driven wheel 46'. The deflection mechanism 4 also includes a first card holder 47 fixedly connected to the first anti-skid belt 45 and slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com