Asbestine near-infrared analyzer with wide applicability

An analyzer and applicability technology, applied in the field of asbestos near-infrared analyzers, can solve the problems of exposed infrared lenses, scratches, dust falling, etc., and achieve the effects of protecting infrared lenses, convenient and accurate angle adjustment, and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

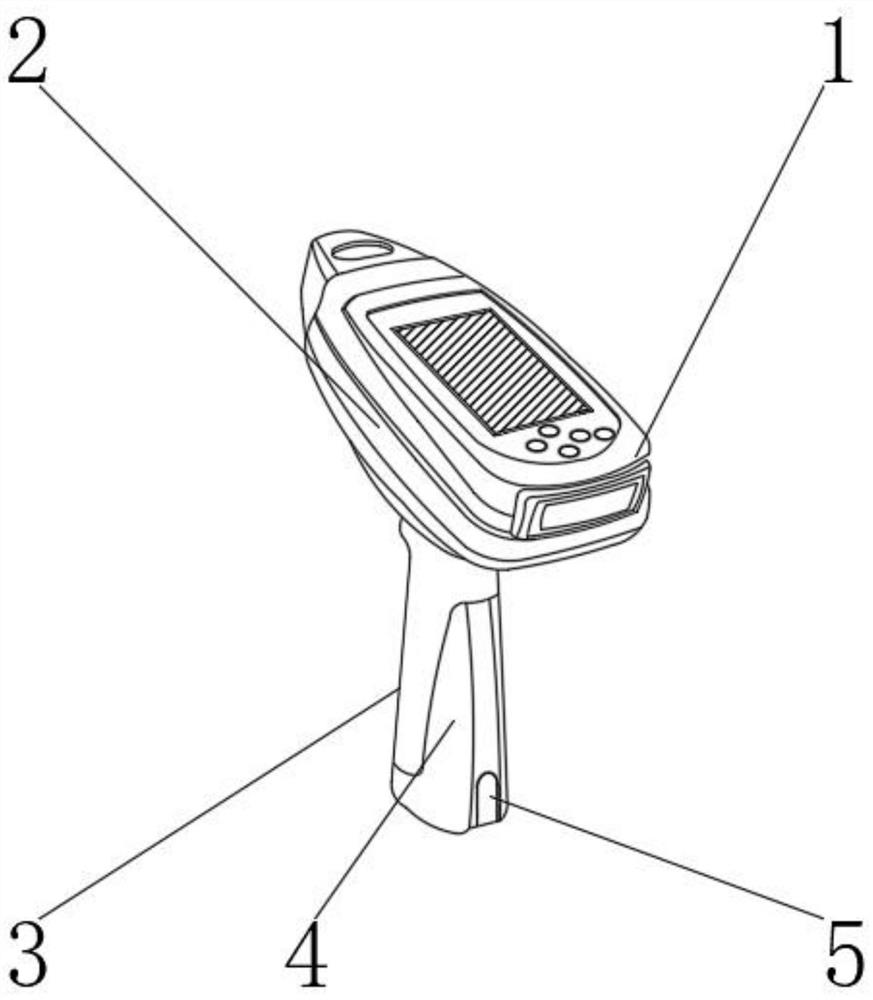

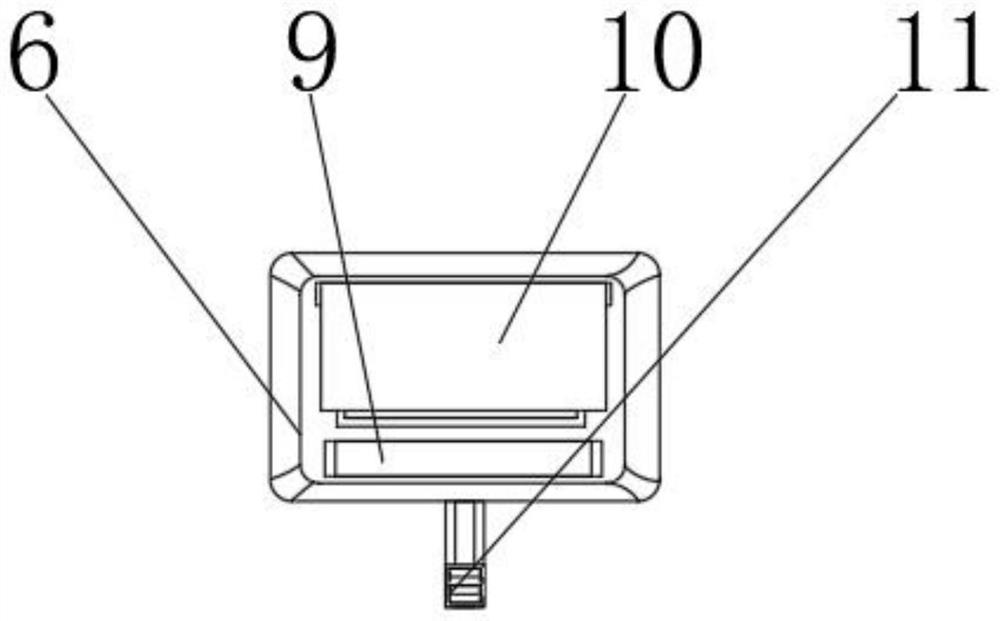

[0028] see Figure 1-3 and Figure 5 , the present invention provides an asbestos near-infrared analyzer with wide applicability, comprising an analyzer body 1, an infrared device 6 is fixedly connected to the outer surface of the rear end of the analyzer body 1, and a flip plate 10 is movably connected to the front end of the infrared device 6 The outer surface of the lower end of the turnover plate 10 is fixedly connected with a negative pole magnet 13, the outer surface of the right side of the turnover plate 10 is fixedly connected with a connecting plate 14, and the outer surface of the right side of the connecting plate 14 is fixedly connected with a tension spring 15, and the tension spring 15 The outer surface on the right side of the analyzer body 1 is fixedly connected with a buckle plate 11, the outer surface of the lower end of the analyzer body 1 is rotatably connected with a second rotating shaft 18, and the outer surface of the second rotating shaft 18 is rotata...

Embodiment 2

[0031] see Figure 1-4 and Figure 6 The inner surface of the upper end of the telescopic base 12 is provided with a limiting sliding groove, the outer surface of the lower end of the first telescopic column 16 is flexibly connected with the inner surface of the upper end of the telescopic base 12 through the limiting sliding groove, and the inner surface of the upper end of the first telescopic column 16 is provided with a limiter. Position groove, the outer wall of the first rotating shaft 17 is rotationally connected with the upper end inner surface of the first telescopic column 16 through the limiting groove, the upper end inner surface of the ball-and-socket column 20 is provided with a limit sliding groove, and the lower end outer surface of the second telescopic column 19 The inner surface of the upper end of the second telescopic column 19 is provided with a limiting groove, and the outer wall of the second rotating shaft 18 is connected to the upper end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com