Bamboo tube skin removing device for miniature carving

A bamboo tube and epidermis technology, which is applied to bark, grinding machines, metal processing equipment, etc., can solve the problems of unsuitable for micro-carving, rough effect, large size and inconvenient movement, etc., to achieve labor-saving in the stabilization process, improve efficiency, and prevent the grinding wheel from shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

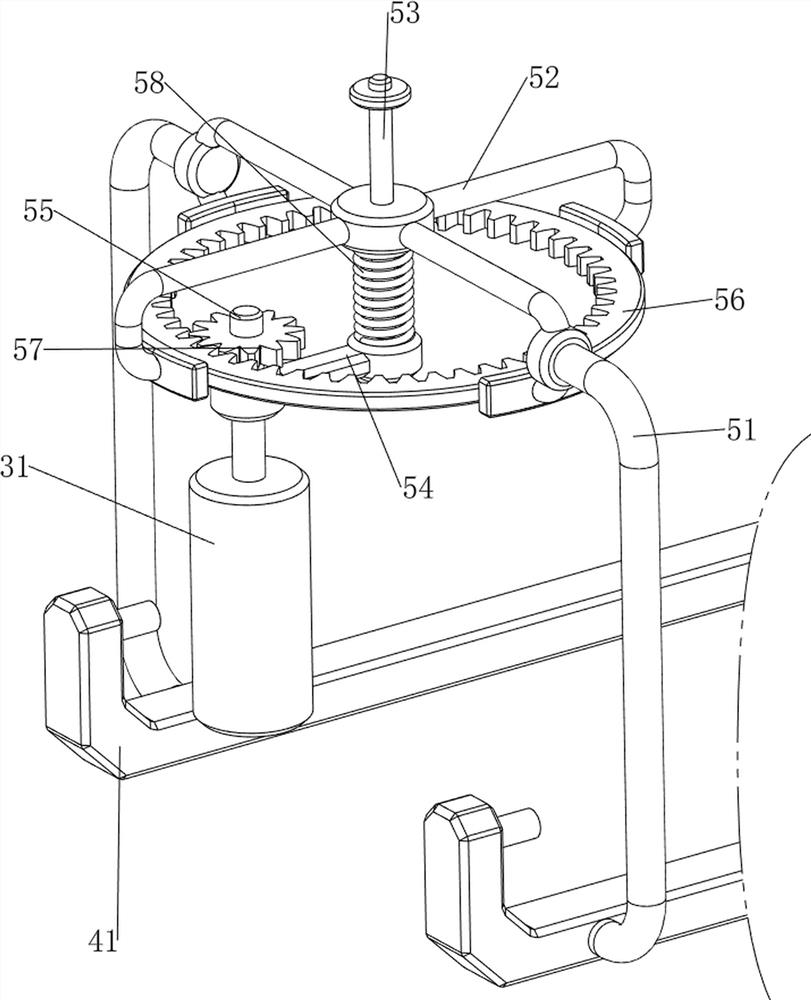

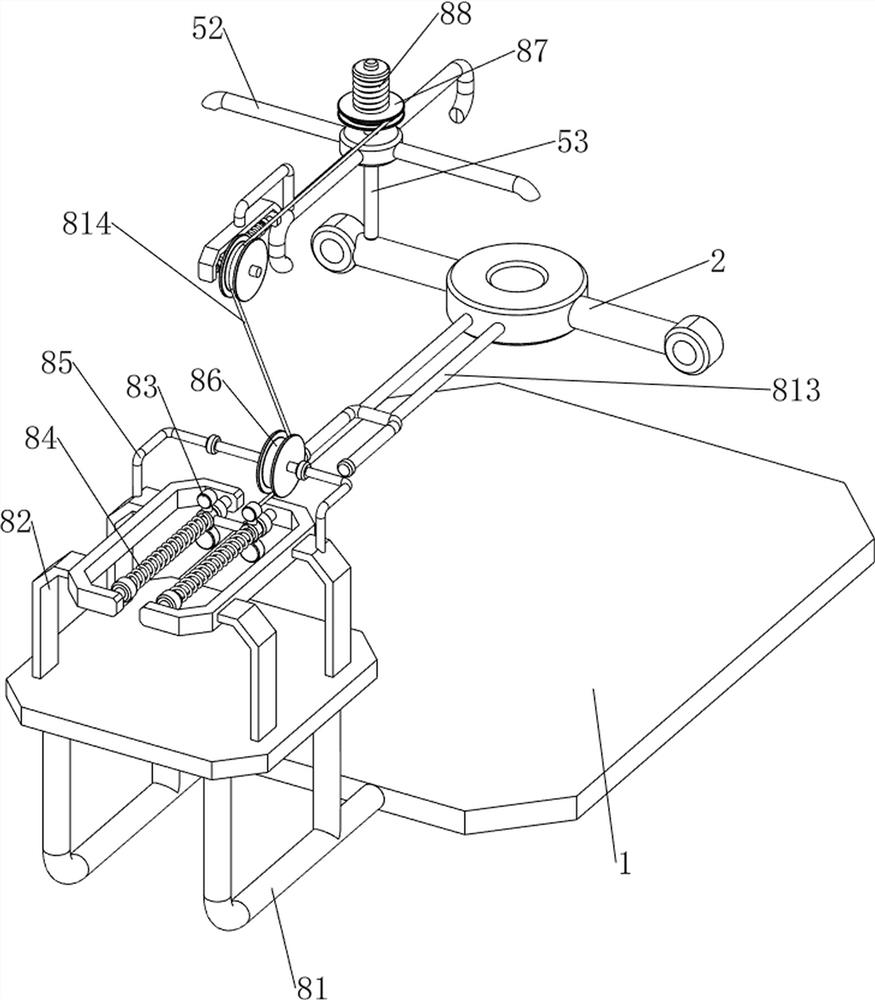

[0081] A bamboo tube peeling device for microcarving, such as figure 1 As shown, it includes a base plate 1, a first support frame 2, a second support frame 3, a grinding wheel 31, a drive mechanism 4 and a rotation mechanism 5, the base plate 1 is provided with a drive mechanism 4, and the drive mechanism 4 is slidably provided with a second A supporting frame 2, a second supporting frame 3 is arranged in the middle of the upper part of the first supporting frame 2, a rotating mechanism 5 is arranged on the driving mechanism 4, and a grinding wheel 31 is arranged on the rotating mechanism 5.

[0082] When the worker needs to remove the skin of the bamboo tube, the worker can first place the bamboo tube on the first support frame 2, the second support frame 3 can stabilize the bamboo tube, and then the worker can start the driving mechanism 4, and then the driving mechanism 4 will move the bamboo tube When contacting with the grinding wheel 31, the worker can make the rotating...

Embodiment 2

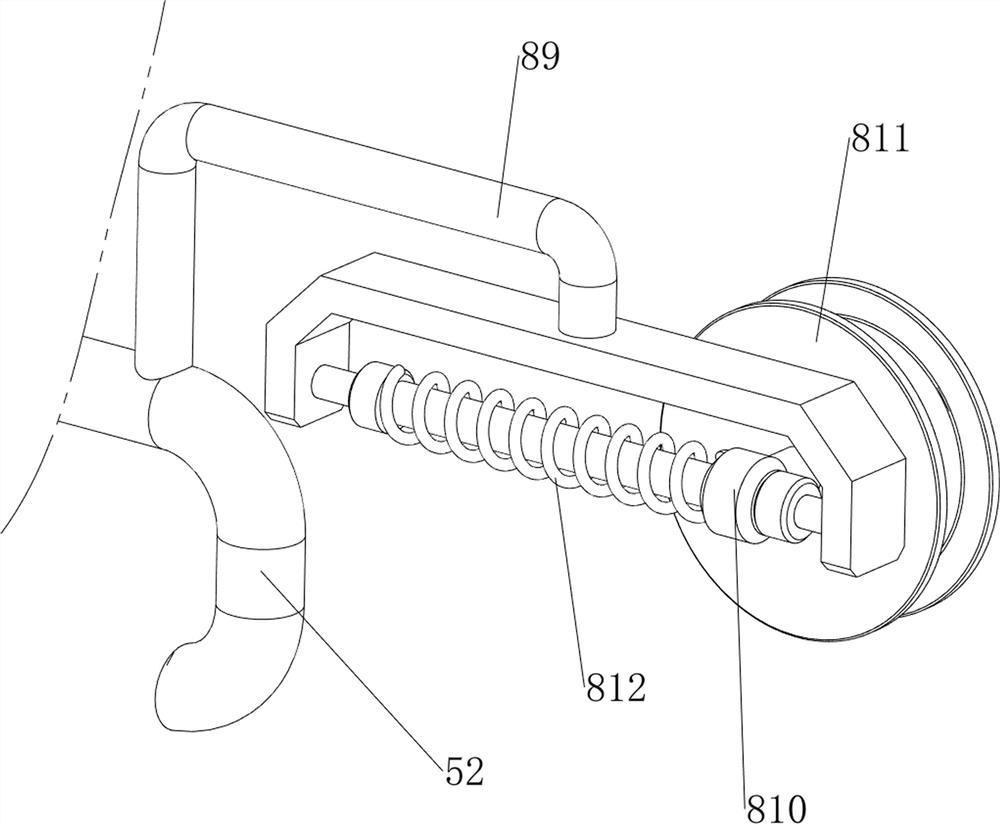

[0084] In a preferred embodiment of the present invention, as figure 2 and image 3 As shown, the driving mechanism 4 includes a third support frame 41, a first slide rail 42, a first spring 43, a first connecting block 44, a cylinder 45 and a second connecting block 46, and the left and right sides of the bottom plate 1 are symmetrically provided with the second Three support frames 41, two third support frames 41 are provided with first slide rails 42, the first slide rails 42 are slidably connected with the first support frame 2, and the upper rear sides of the two first slide rails 42 are all socketed There is a first spring 43, the two ends of the first spring 43 are respectively connected on the first support frame 2 and the first slide rail 42, the rear sides of the two third support frames 41 are connected with the first connecting block 44, and the two first A cylinder 45 is fixedly connected between the connection blocks 44 by bolts, and the telescoping rod of the ...

Embodiment 3

[0089] In a preferred embodiment of the present invention, as Figure 4-Figure 8 As shown, a fixing mechanism 6 is also included. The fixing mechanism 6 includes a sixth support frame 61, a first stop block 62, a second spring 63, a pressing block 64 and a third spring 65. There is a sixth support frame 61, on which the sixth support frame 61 is slidably provided with a first limiter 62, the lower part of the first limiter 62 is sleeved with a second spring 63, and the upper end of the second spring 63 is connected to the sixth support frame 61, the top of the second support frame 3 is evenly slidable and is provided with a briquetting block 64, the quantity of the briquetting block 64 is four, the briquetting block 64 is sleeved with a third spring 65, and the two ends of the third spring 65 are respectively connected to the briquetting block 64 and the second support frame 3 , the first limiting block 62 cooperates with the pressure block 64 .

[0090] After the worker plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com