Preparation method and stripping method of heat-resistant flame-retardant conductive peelable pressure-sensitive adhesive

A pressure-sensitive adhesive and heat-resistant technology, applied in the direction of conductive adhesives, adhesives, adhesive additives, etc., can solve the problem that it is difficult to ensure that the protected object is not damaged, and achieve long environmental protection storage time, good heat resistance and flame retardancy , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

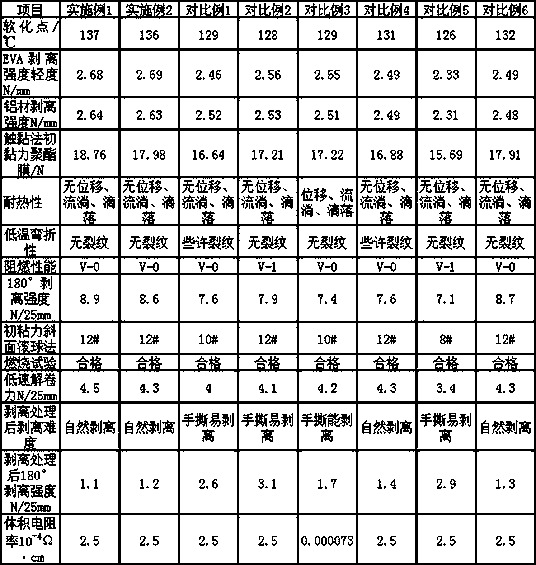

Examples

Embodiment 1

[0023] A preparation method of heat-resistant and flame-retardant conductive peelable pressure-sensitive adhesive, comprising the steps of:

[0024] (1) Add 120 parts of a mixture of methylcyclohexyl diisocyanate and lysine methyl diisocyanate in a ratio of 70:30 by weight to the reactor, slowly add 130 parts of 2-ethylhexanol and N-ethylhexanol 0.8 parts of morpholine and 0.2 parts of stannous octoate were cooled outside the reactor to control the temperature at 100°C, then 14 parts of nitrile rubber and 0.08 parts of dibutyltin lauryl were added and reacted at 120°C for 30 minutes to obtain prepolymer A ;

[0025] (2) Under nitrogen protection and stirring, add 2.8 parts of n-butyllithium n-hexane solution dropwise to 25 parts of ferrocene and 93 parts of n-hexane evenly dispersed, then add 1.5 parts of tetramethylethylenediamine, and stir the mixture React for 3 hours, filter under a nitrogen atmosphere, wash with n-hexane, remove the n-hexane solvent by rotary evaporation...

Embodiment 2

[0036] A preparation method of heat-resistant and flame-retardant conductive peelable pressure-sensitive adhesive, comprising the steps of:

[0037] (1) Add 154 parts of a mixture of methylcyclohexyl diisocyanate and lysine methyl diisocyanate in a ratio of 60:40 by weight to the reactor, slowly add 110 parts of 2-ethylhexanol and N-ethylhexanol 0.8 parts of morpholine and 0.2 parts of stannous octoate were cooled outside the reactor to control the temperature at 100°C, then 14 parts of nitrile rubber and 0.08 parts of dibutyltin lauryl were added and reacted at 120°C for 30 minutes to obtain prepolymer A ;

[0038] (2) Under nitrogen protection and stirring, add 2.8 parts of n-butyllithium n-hexane solution dropwise to 22 parts of ferrocene and 93 parts of n-hexane evenly dispersed, then add 0.5 parts of tetramethylethylenediamine, and stir the mixture React for 3 hours, filter under a nitrogen atmosphere, wash with n-hexane, remove the n-hexane solvent by rotary evaporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com