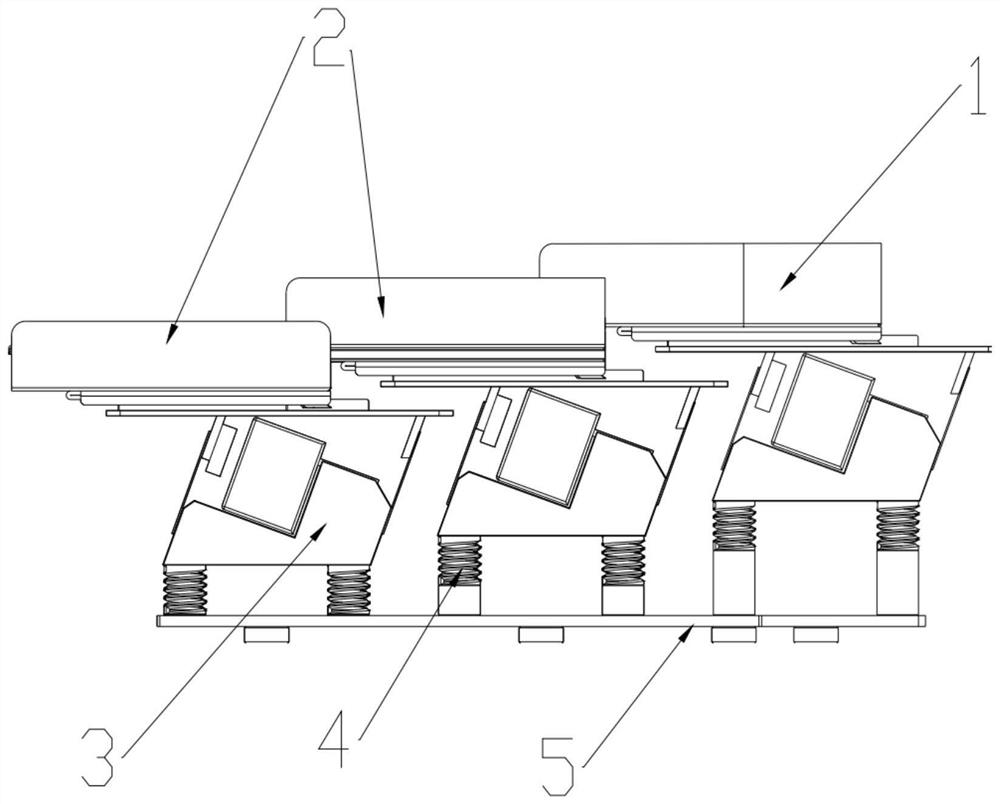

High-precision multi-stage vibration feeding device and method

A feeding device, high-precision technology, applied in the direction of measuring device, vibrating conveyor, transportation and packaging, etc., can solve the problems of drug weight control, total amount error of packaging samples, etc., and achieve the effect of controlling weighing error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

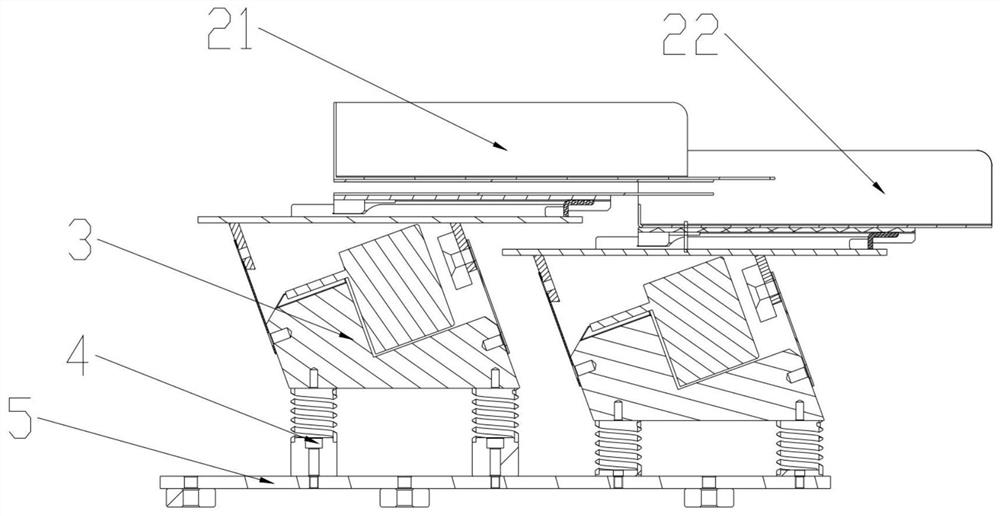

[0032] Example 1: If the weight of one portion is 10g, then set the first preset weight to 9.5g-9.8g, and the second preset weight to 10g; when the weight of the material sensed by the weighing bucket reaches 9.5g-9.8g, the control terminal controls The vibrating component 3 stops the vibrating feeding of the primary feeding trough 1, and when the weight of the material sensed by the weighing bucket reaches 10g, the control end controls the vibrating component 3 to stop the vibration completely.

Embodiment 2

[0033] Example 2: If the weight of one portion is 1g, then set the first preset weight to 0.6g-0.8g, and the second preset weight to 1g; when the weight of the material sensed by the weighing bucket reaches 0.6g-0.8g, the control terminal controls The vibration component 3 stops the vibration feeding of the primary feed tank 1, and when the weight of the material sensed by the weighing bucket reaches 1g, the control end controls the vibration component 3 to stop the vibration completely.

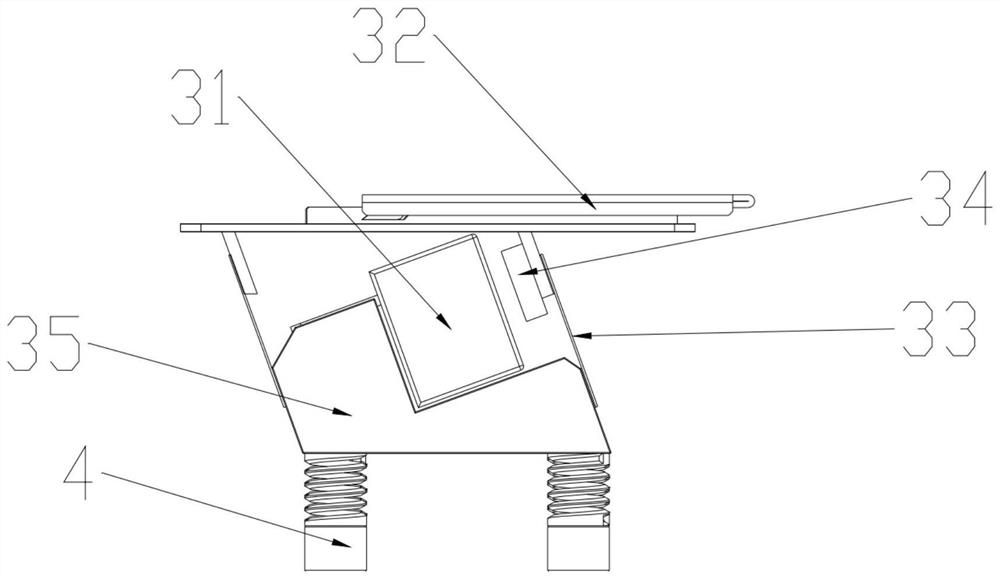

[0034] A high-precision multi-stage vibration feeding method, please refer to Figure 1-Figure 5 , applied to a high-precision multi-stage vibration feeding device, comprising the following steps:

[0035] The primary feeding tank 1 receives the material from the collecting hopper, and all the vibrating components 3 are simultaneously activated to control the primary feeding tank 1 to vibrate and feed the material into the fine-tuning feeding tank 2;

[0036] The fine-tuning feeding trough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com