A processing device for galvanized wire and its processing technology

A processing device and galvanizing tank technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of dip galvanizing quality reduction, doping, falling impurities, etc., to achieve extended cooling Effects of time, uniform heating, and slowing down of inflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

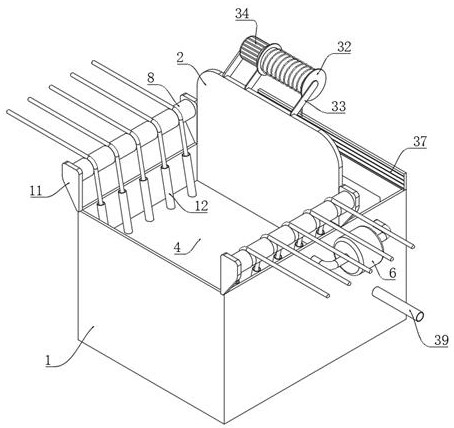

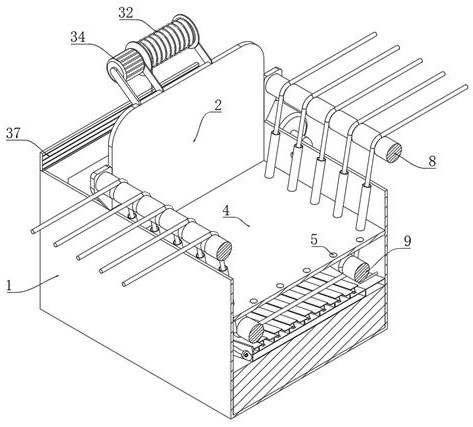

[0046] like Figure 1-9 A processing device for galvanized wire shown includes a galvanizing tank 1, a partition 2 is vertically fixed inside the galvanizing tank 1, and the partition 2 divides the inner space of the galvanizing tank 1 into a heating chamber and a galvanizing chamber, A slag discharge port 3 is provided at the bottom of the partition 2, and the slag discharge port 3 is used to connect the heating chamber and the galvanizing chamber;

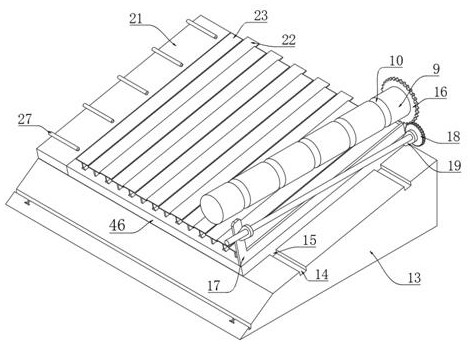

[0047] A heat shield 4 is horizontally fixed inside the galvanizing chamber. A plurality of zinc discharge through holes 5 are provided on the top surface of the heat shield 4 away from the partition 2. A zinc pump 6 is fixed on the side of the galvanizing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com