Hot plug structure based on NMOS pull-up driver

A hot-swapping and driver technology, applied in the direction of logic circuit coupling/interface, electrical components, logic circuit connection/interface arrangement using field effect transistors, etc., can solve the problem of burning out the buffer circuit and failing to meet the hot-swapping function of the circuit , affecting the bus signal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

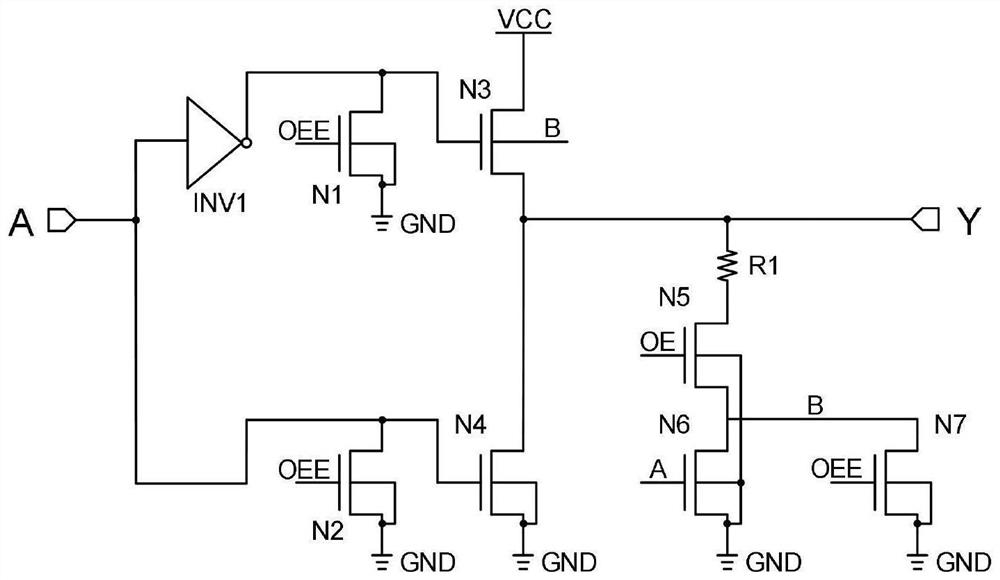

[0015] The present invention provides a hot-swap structure based on NMOS pull-up driver, its structure is as follows figure 1 As shown, it includes input terminal A, output terminal Y, NMOS transistors N1~N7, inverter INV1 and resistor R1; input terminal A is connected to the input terminal of inverter INV1, and the output terminal of the inverter INV1 is connected to NMOS at the same time The drain terminal of the tube N1 and the gate terminal of the NMOS tube N3; the drain terminal of the NMOS tube N3 is connected to the power supply VCC, and the source terminal is connected to the drain terminal of the NMOS tube N4 and the output terminal Y;

[0016] The input terminal A is connected to the drain terminal of the NMOS transistor N2 and the gate terminal of the NMOS transistor N4, and the drain terminal of the NMOS transistor N4 is connected to the source terminal of the NMOS transistor N3 and the output terminal Y;

[0017] The output terminal Y is connected to one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com