Device for rapidly detecting deformation and deformation recovery of asphalt and test method

A technology of deformation recovery and test method, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., to achieve the effect of rapid evaluation and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

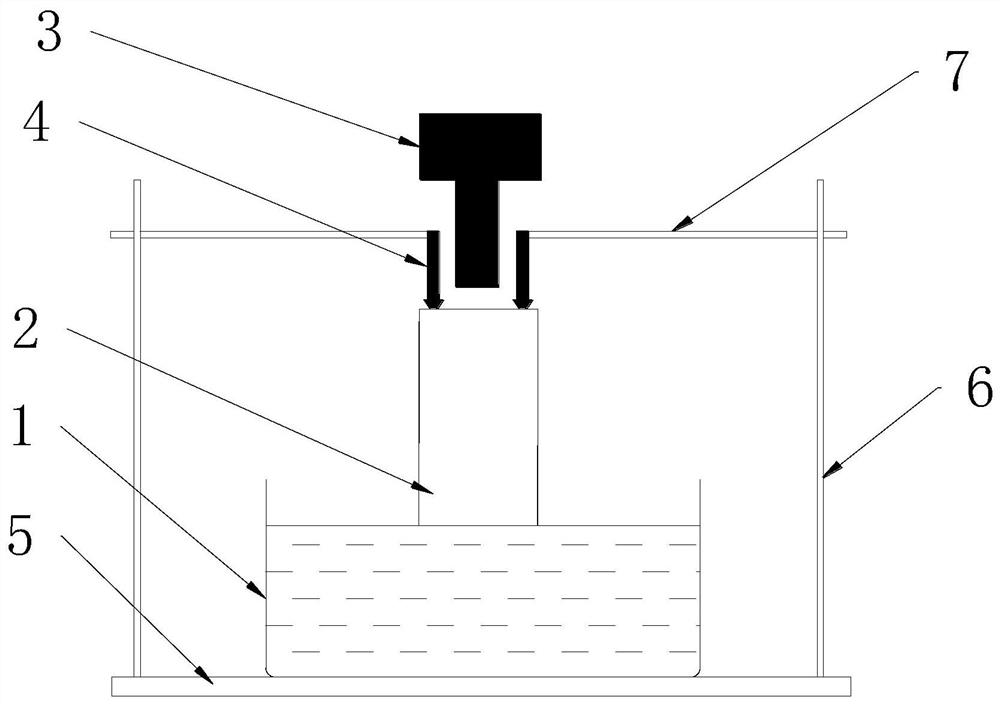

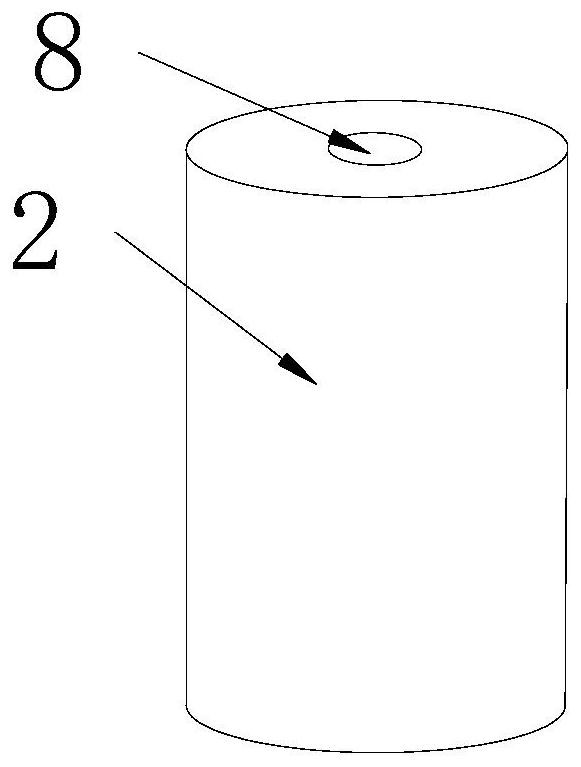

[0044] as attached figure 1 As shown, the device for quickly detecting asphalt deformation and deformation recovery of the present invention has a structure including a frame body, an asphalt storage box 1 is installed at the bottom of the frame body, an indenter 2 is installed above the asphalt storage box 1, and an indenter 2 is installed on the top of the asphalt storage box 1. A universal press pressure head 3 is installed above, and a displacement sensor 4 (LVDT) is installed on both sides of the universal press pressure head 3 respectively. The asphalt storage box 1 is made of a high-strength aluminum alloy box; the penetration head 2 is made of a high-strength light aluminum alloy head.

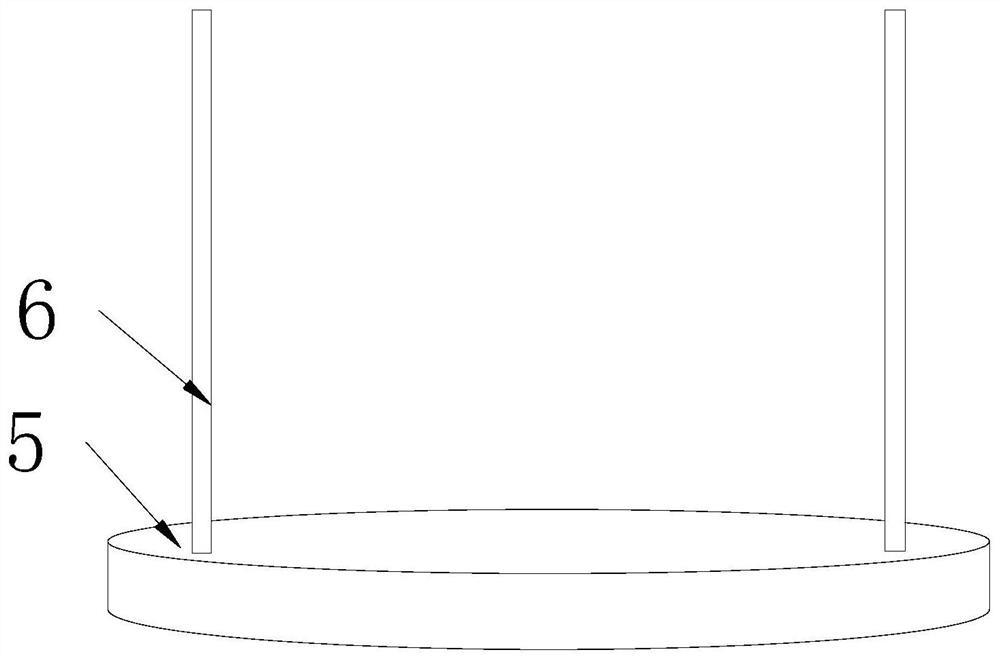

[0045] as attached image 3 As shown, the frame body in this embodiment includes a bracket base 5, two vertical brackets 6 are installed on the bracket base 5, a horizontal bracket connecting rod 7 is respectively installed on the upper ends of the two vertical brackets 6, and the pre...

Embodiment 2

[0048] The test method of rapid detection asphalt deformation and deformation recovery of the present invention, the method is specifically as follows:

[0049] S1. Melt any type of asphalt to be tested and pour it into the asphalt storage box 1, and add the asphalt to a height of 2 / 3 of the body of the asphalt storage box 1;

[0050] S2. Put the asphalt in the asphalt storage box 1 into a high and low temperature temperature box for heat preservation, so that the asphalt reaches the required temperature; wherein, the temperature can be 20°C or -5°C respectively;

[0051]S3. Put the frame as a whole on the universal press, and fix the LVDT on the horizontal bracket with 7 bars;

[0052] S4. Place the insulated asphalt storage box 1 in the center of the support base 5, place the penetration indenter 2 in the center of the asphalt in the asphalt storage box 1, and gently press the LVDT against both sides of the upper end of the penetration indenter, and place the LVDT zeroing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com