Sliding base-isolation device

A shock isolation, sliding surface technology, applied in shockproof, clothing, spring/shock absorber, etc., can solve the problems of reduced use frequency, heavier weight, lower cost competitiveness, etc., to achieve the effect of excellent sliding durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

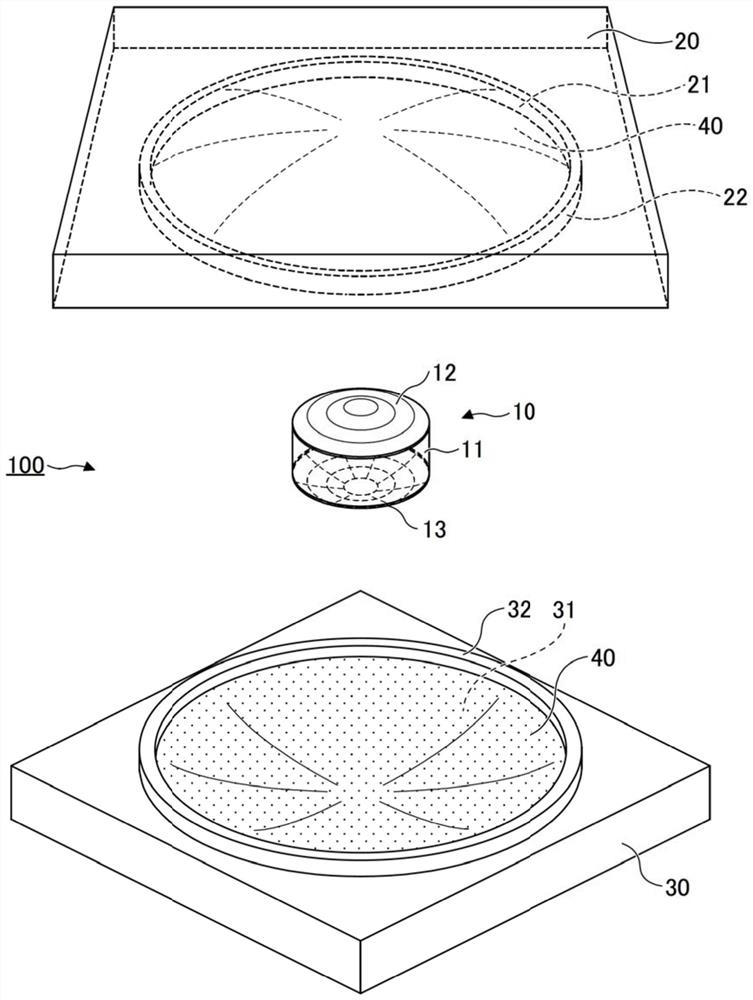

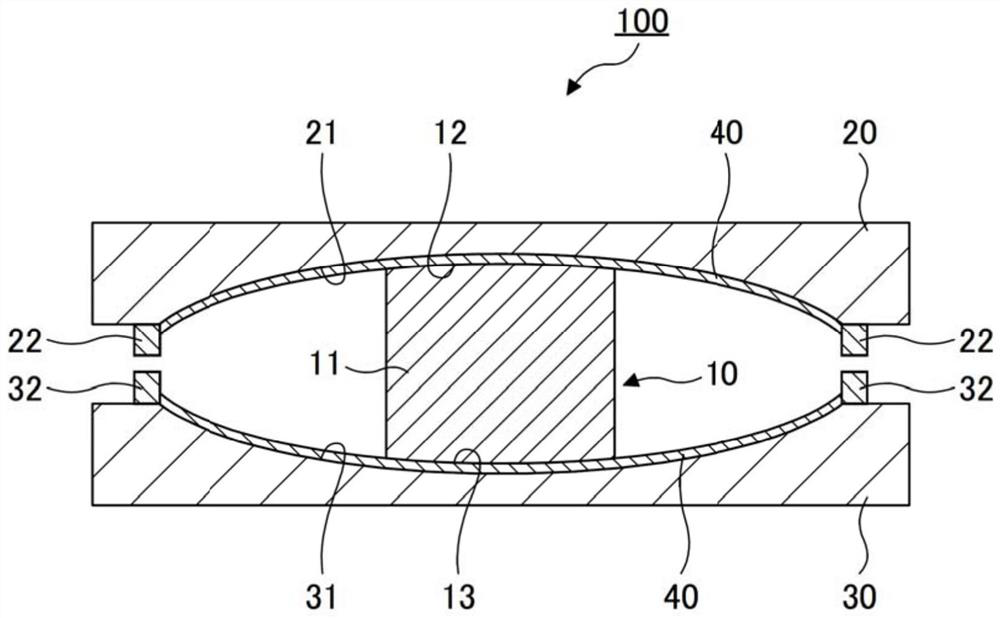

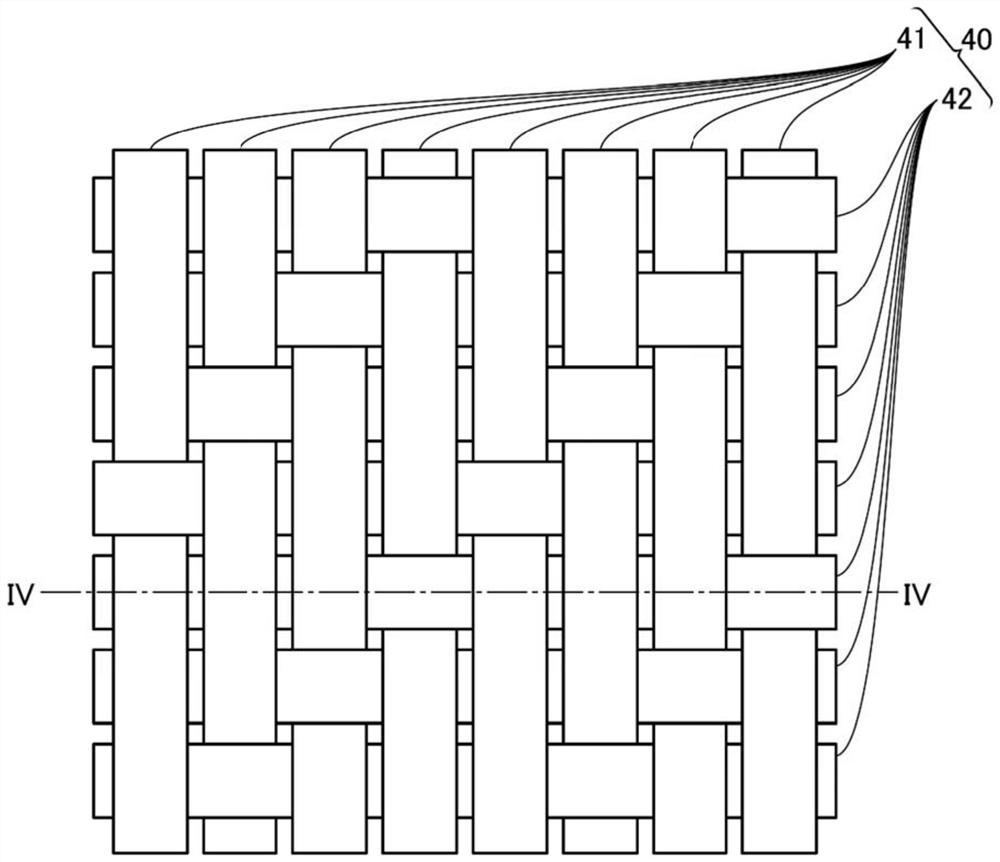

[0043] Next, the sliding vibration isolation device according to each embodiment will be described with reference to the drawings. In addition, in this specification and drawing, the same code|symbol is attached|subjected to the substantially same structural element, and the overlapping description may be omitted.

[0044] [Sliding vibration isolation device of the first embodiment]

[0045] First, refer to Figure 1 to Figure 4 An example of the sliding vibration isolation device according to the embodiment will be described. here, figure 1 It is an exploded perspective view of the sliding vibration isolation device of the first embodiment, figure 2 It is a longitudinal sectional view of the sliding vibration isolation device of the first embodiment. also, image 3 is a plan view of a friction material composed of a single layer of fabric viewed from above, Figure 4 is along image 3 The cross-sectional view cut along the line IV-IV in , is a diagram illustrating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com