Crystalline polyamide based resin composition

一种聚酰胺树脂、树脂组合物的技术,应用在建筑物构造、建筑物紧固器件、门等方向,能够解决机械强度下降、模压加工性差、用途限制等问题,达到良好模压加工性、优异滑动耐久性、耐受性不退化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

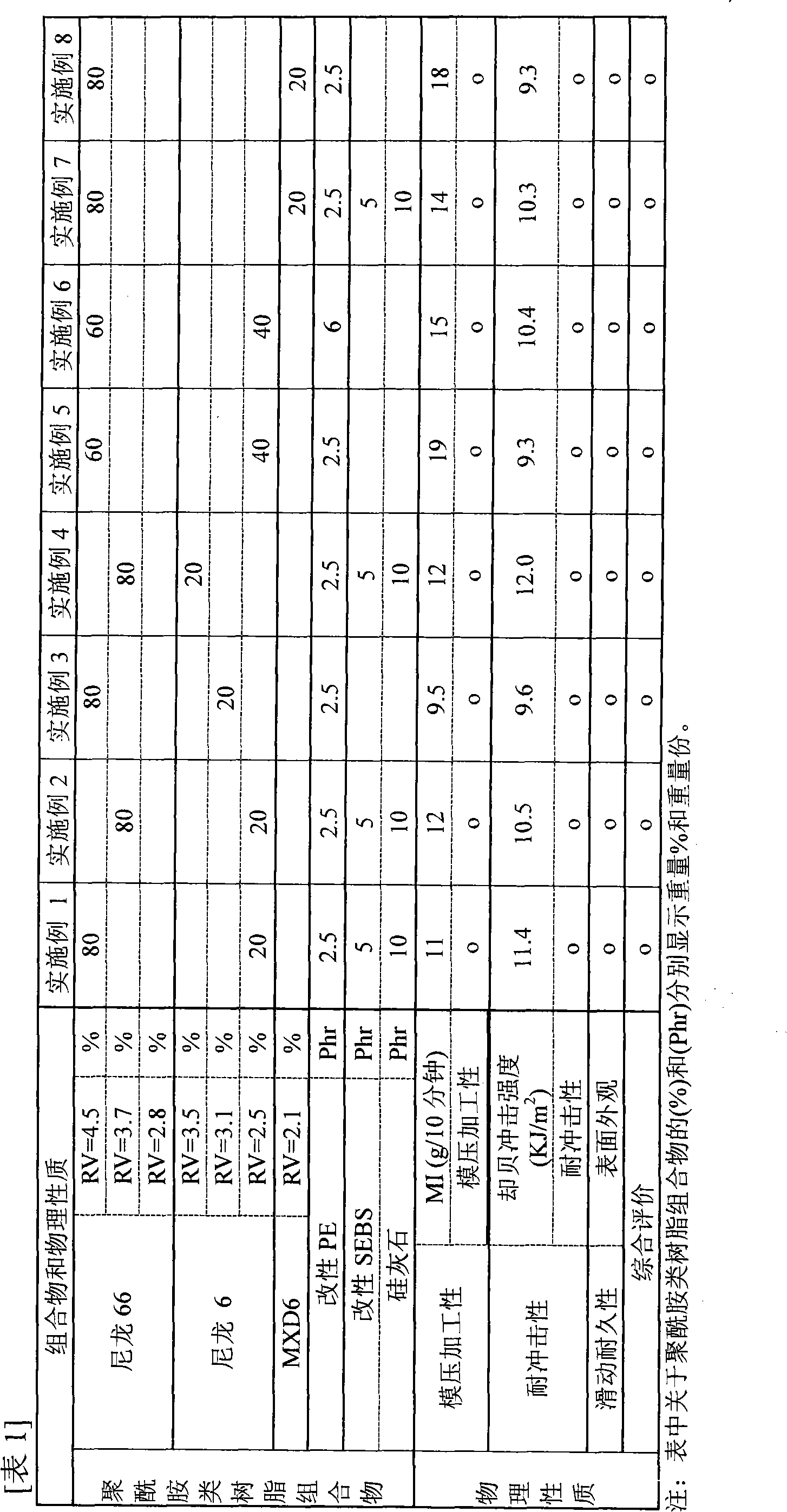

[0040] Now, the present invention will be described more specifically by using the following examples, but the present invention is not limited to the examples.

[0041] The raw materials used in Examples and Comparative Examples of the present invention are as follows.

[0042] For the crystalline polyamide resin, the following (a) to (f) are used.

[0043] (a) Polyamide 66 (RV=4.5, melting point=266°C): Ultramide A5 (BASF)

[0044] (b) Polyamide 66 (RV=3.7, melting point=265°C): Amiran CM 3036 (Toray)

[0045] (c) Polyamide 66 (RV=2.8, melting point=265°C): Amiran CM 3001N (Toray)

[0046] (d) Polyamide 6 (RV=3.5, melting point=234°C): Toyobo Nylon T-850 (Toyobo)

[0047] (e) Polyamide 6 (RV=3.1, melting point=233°C): Toyobo Nylon T-820 (Toyobo)

[0048] (f) Polyamide 6 (RV=2.5, melting point=233° C.): Toyobo Nylon T-800 (Toyobo)

[0049] (g) MXD 6 (RV=2.1, melting point=242°C): Toyobo Nylon T-600 (Toyobo)

[0050] In addition, acid-modified PE [MME 001 (Grand Polypro)...

Embodiment 6

[0061] Example 6 is a composition in which the added amount of modified polyethylene was increased, but moldability, impact resistance, and sliding durability all had good results.

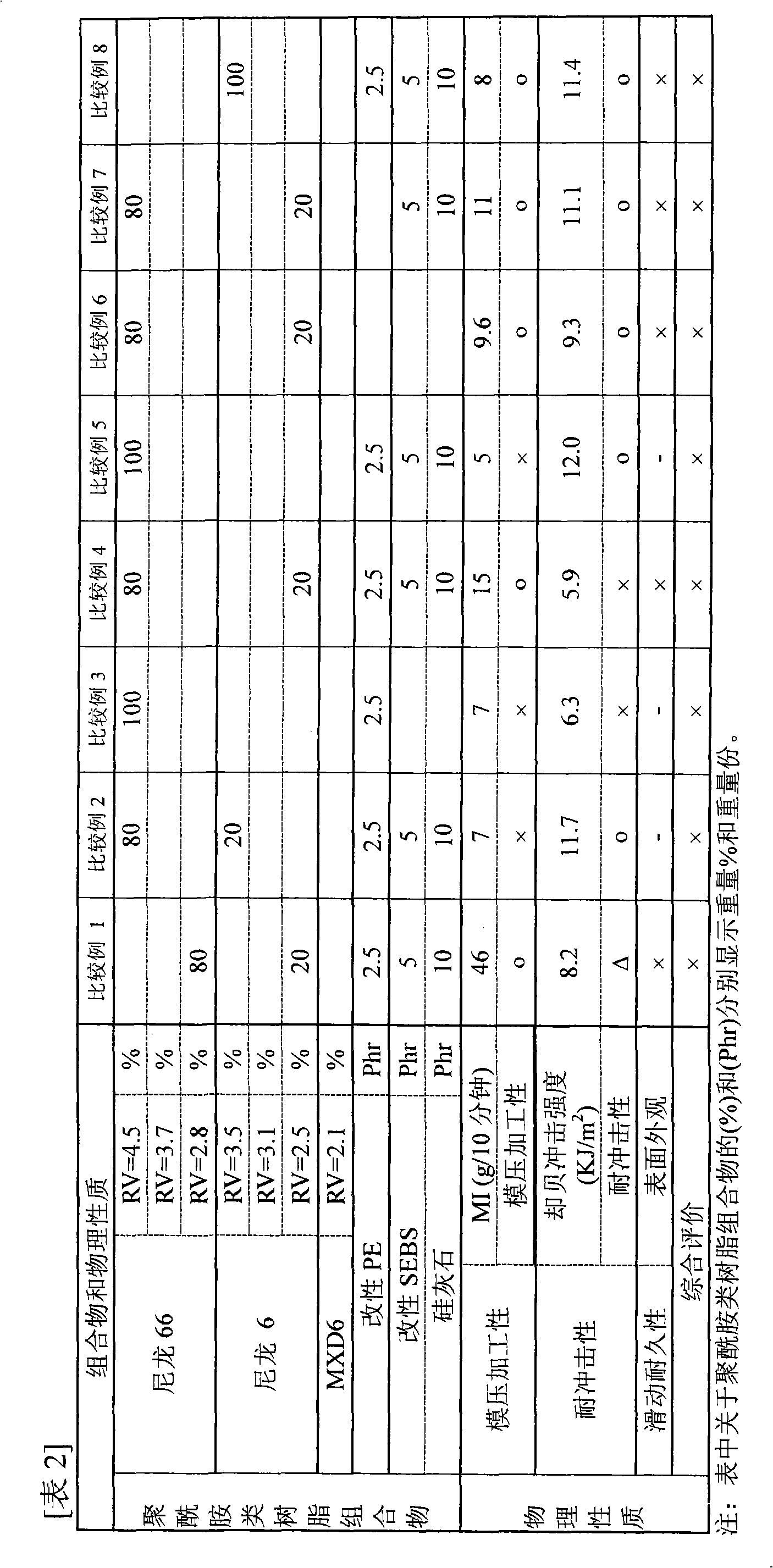

[0062] On the other hand, Comparative Example 1 is a composition in which the relative viscosity RV of polyamide 66 is low. Although the moldability was good, the sliding durability was poor, and significant removal of the surface occurred on the sliding surface. Due to the significant deterioration in this property, it cannot be used for a door opening limiter. Comparative Example 2 is a composition in which the relative viscosity RV of polyamide 6 is high, but in this system, fluidity is poor, whereby a door opening stopper cannot be produced and evaluation of sliding durability of an actual product cannot be performed. Comparative Examples 3 and 5 are compositions of the polyamide 66 system alone having a high relative viscosity, however, due to its poor moldability, sliding durability evaluat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com